Automatic power supply production process

A technology of production process and power supply products, applied in the direction of electrical components, electrical components, etc., can solve the problems of troublesome transportation work, product inventory in process, difficulty in forming continuous operation, and low manual production efficiency, so as to achieve the quality of overcoming human factors problems, reduce logistics turnover, and reduce the effect of operating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] The invention integrates each segmented process into one flow layout, thereby improving production efficiency and effectively controlling product quality.

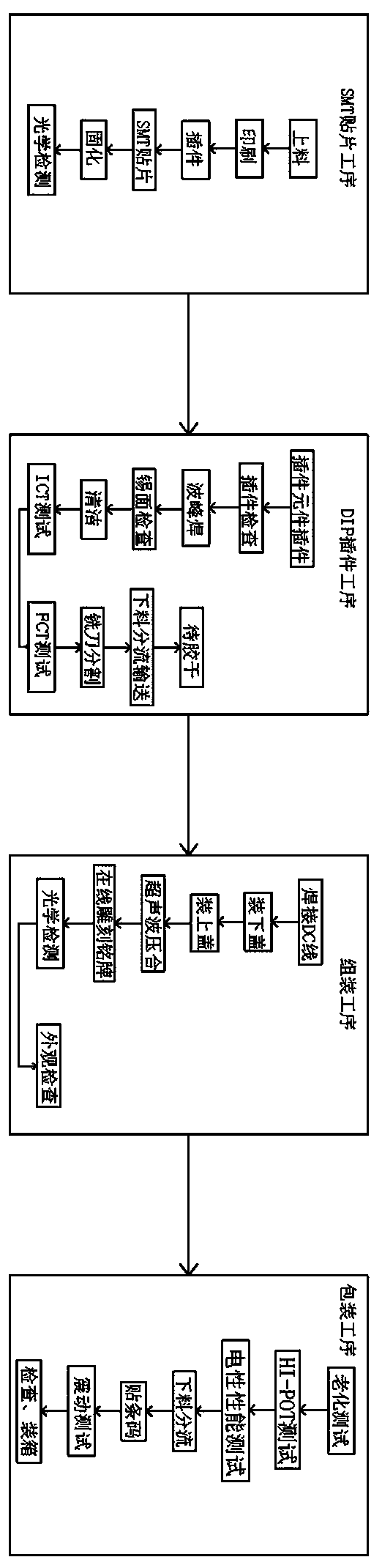

[0042] as attached figure 1 As shown, the present invention discloses a kind of automatic production process of power supply, comprising the following steps:

[0043] S1, SMT placement and AI, absorb the PCB board on the transmission track, and transport it to the SMT placement and AI process to perform SMT placement and automatic plug-in operation on the PCB board.

[0044] S2, DIP plug-in, transfers the PCB board from the SMT placement process to the transmission track through the connecting table assembly line, and transports it to the D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com