Full-automatic plate cleaning system

A fully automatic, control system technology, applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems of high labor cost and large amount of labor, and achieve the effect of reducing labor intensity, reducing labor cost and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

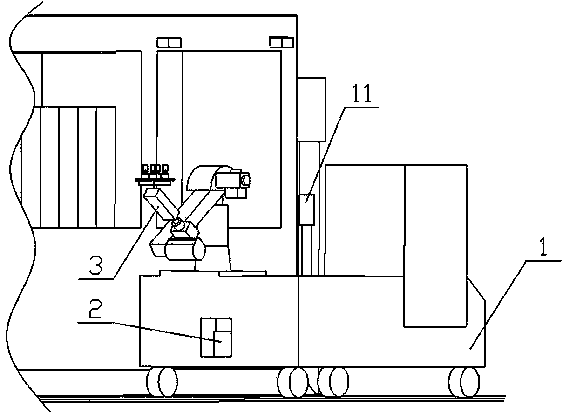

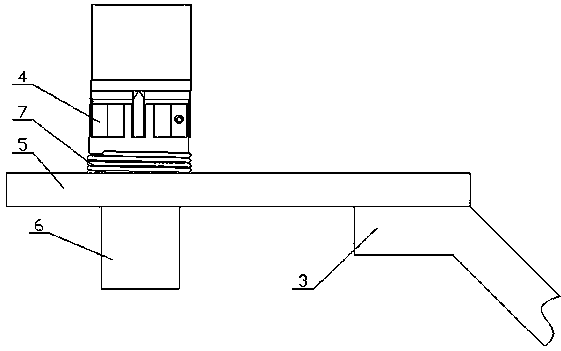

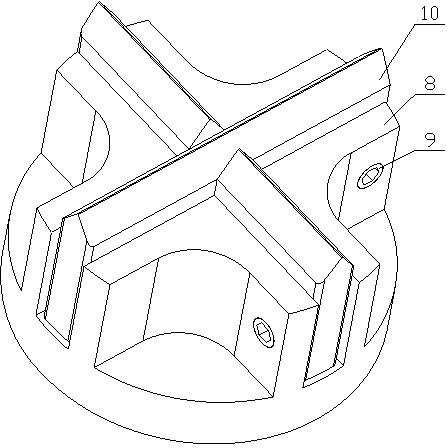

[0017] Such as figure 1 It shows an embodiment of the automatic plate cleaning system of the present invention, including an AGV car 1, the AGV car 1 is equipped with a laser navigation system 11, the front and rear parts of the AGV car 1 are equipped with a radar scanning head 2, and the AGV car 1 is equipped with There is a robot, and the front end of the robot is equipped with a scraper combination device; the robot includes a control system and a six-joint swing arm 3; as figure 2 As shown, the scraper combination device includes four cleaning blades 4, and the four cleaning blades 4 are all fixed on the positioning plate 5, and the positioning plate 5 is connected with the robot. Drive described clearing board cutter head 4, all be provided with adjustable spring 7 between each clearing board cutter head 4 and positioning plate 5; image 3 As shown, each cleaning cutter head 4 is provided with a fixture 8, and a spatula 10 is connected to the fixture 8 through a top wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com