Automated building block production line

A production line and block technology, applied in the field of operation and transportation, can solve the problems of inaccurate feeding control, complex structure of the turning machine, and insufficient system stability, etc., and achieve the effects of simple structure, improved system stability, and stable motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

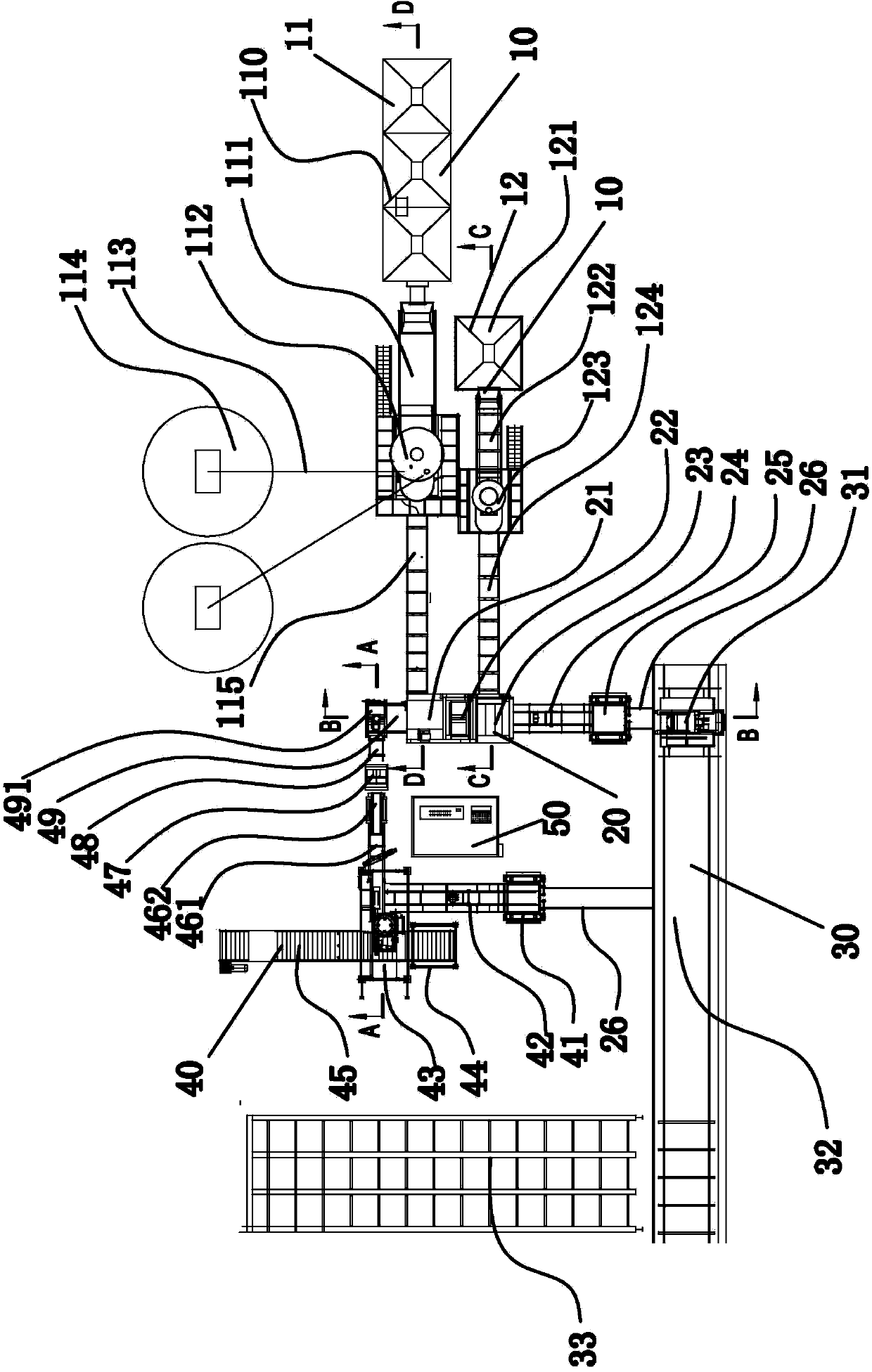

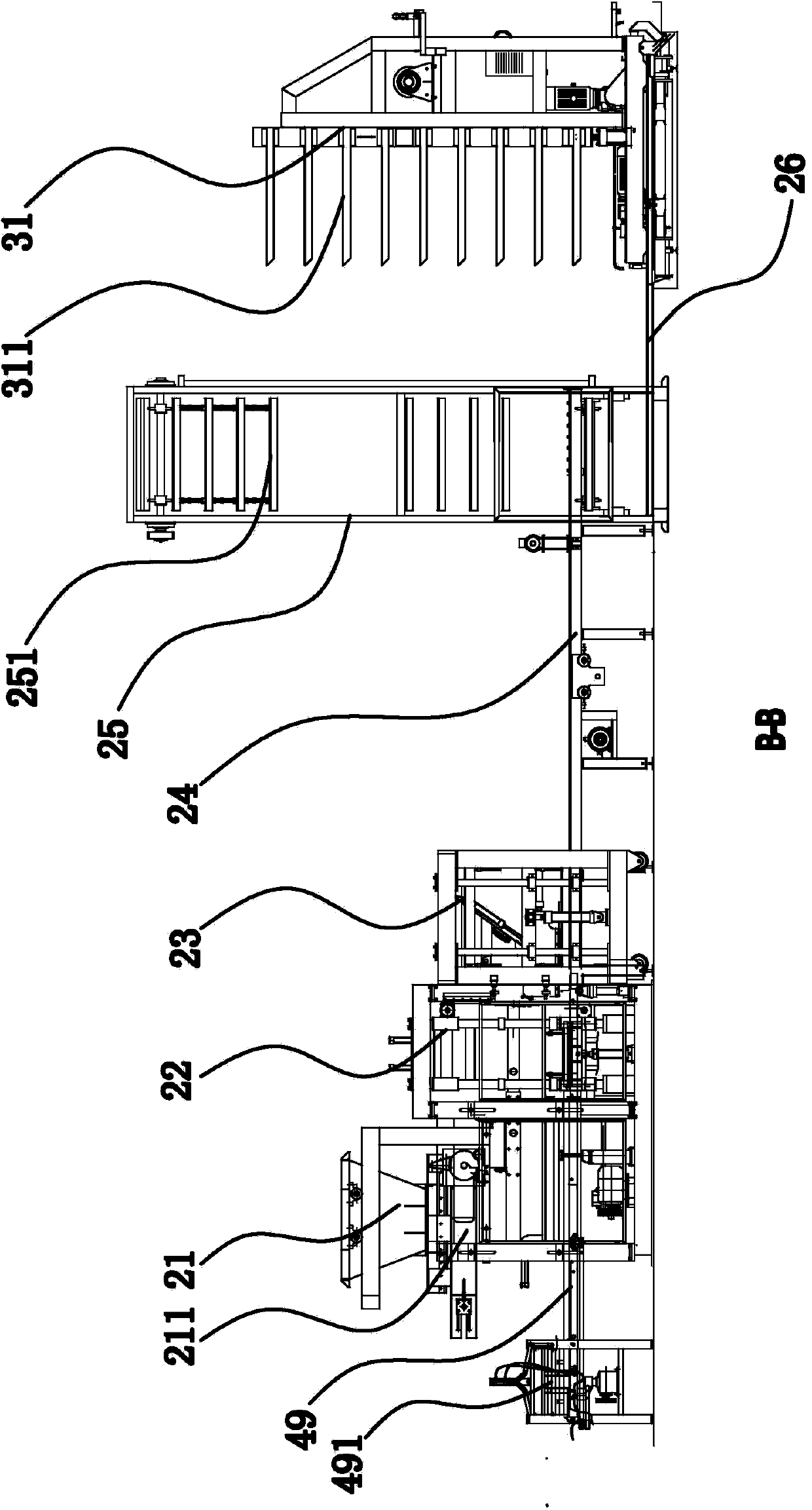

[0042] like figure 1 As shown, the present invention includes a batching system 10 , a block forming system 20 , a maintenance system 30 , a pallet recycling system 40 and an automatic control system 50 .

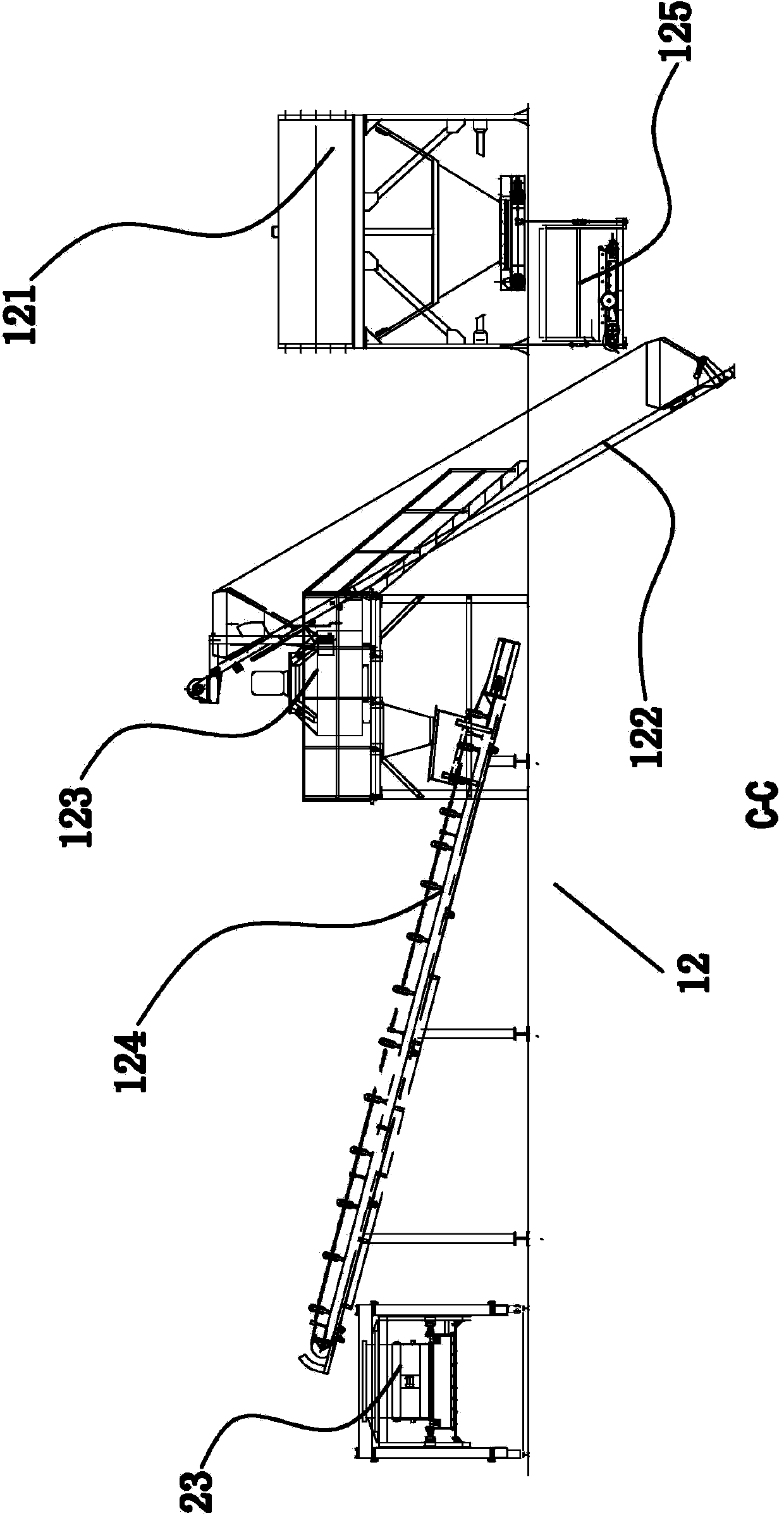

[0043] like figure 1 , figure 2 and Figure 4 As shown, the batching system 10 includes an aggregate conveying line 11 and a fabric conveying line 12, the aggregate conveying line 11 includes an aggregate bin 110 and a cement bin 114, and a discharge belt 116 is arranged at the lower part of the outlet of the aggregate bin 110, The discharge belt 116 is installed on the weighing belt 117, the lower part of the extension end of the discharge belt 116 is provided with an aggregate conveyor belt 111, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com