Resin composite board and production method thereof

A technology of resin compounding and production method, applied in synthetic resin layered products, chemical instruments and methods, paper/cardboard layered products, etc., can solve the problems of long production cycle, low interface bond strength, inconsistent shrinkage rate, etc. To achieve the effect of reducing material loss, reducing material turnover, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Exemplary embodiments of the present invention are described below with reference to the drawings. It should be understood that the following description of the present invention is only used to illustrate the principle and exemplary implementation of the present invention, and is not intended to limit the scope of the present invention.

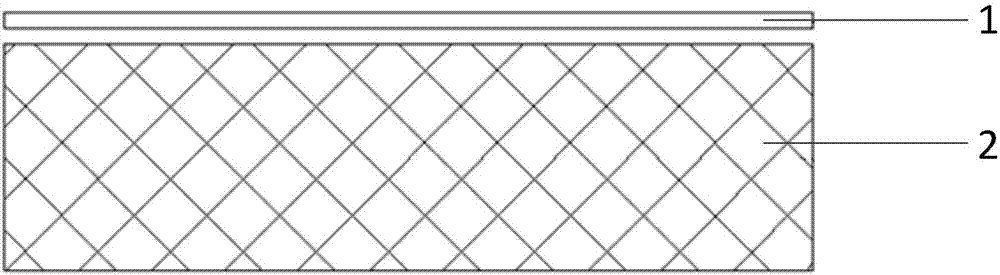

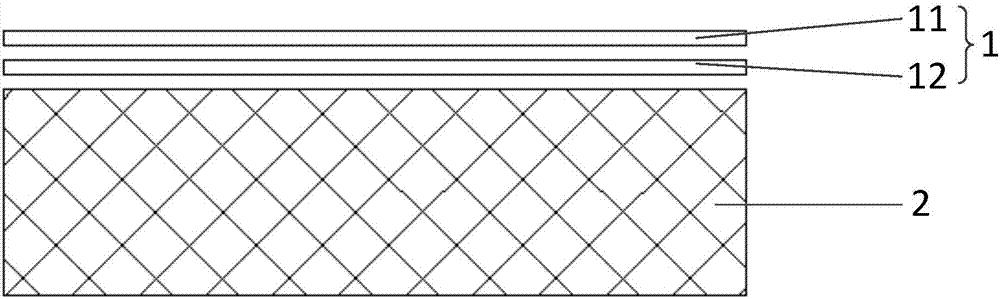

[0047] refer to figure 1 , in the first embodiment of the present invention, the resin composite board includes two layers, namely, the surface layer 1 and the resin substrate layer (ie, the resin composite substrate) 2 . The surface layer 1 can be formed by one or more of plastic film, bamboo chips, wood chips, wear-resistant materials, rubber, paper, leather, metal, cloth, carpet, cork, composite materials and the like. The resin base layer 2 is mainly composed of resin powder.

[0048] In this embodiment, the resin base material layer (ie, the resin composite base material) 2 may be expressed in the form of three layers of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com