Modulation assembly movement mechanism and beverage machine comprising the same

A motion mechanism and component technology, applied in beverage preparation devices, home appliances, applications, etc., can solve problems such as easy locking, uncoordinated motion of extraction cylinder and ejector, and motion blockage, so as to achieve smooth motion and not easy Faults, effects of motor coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

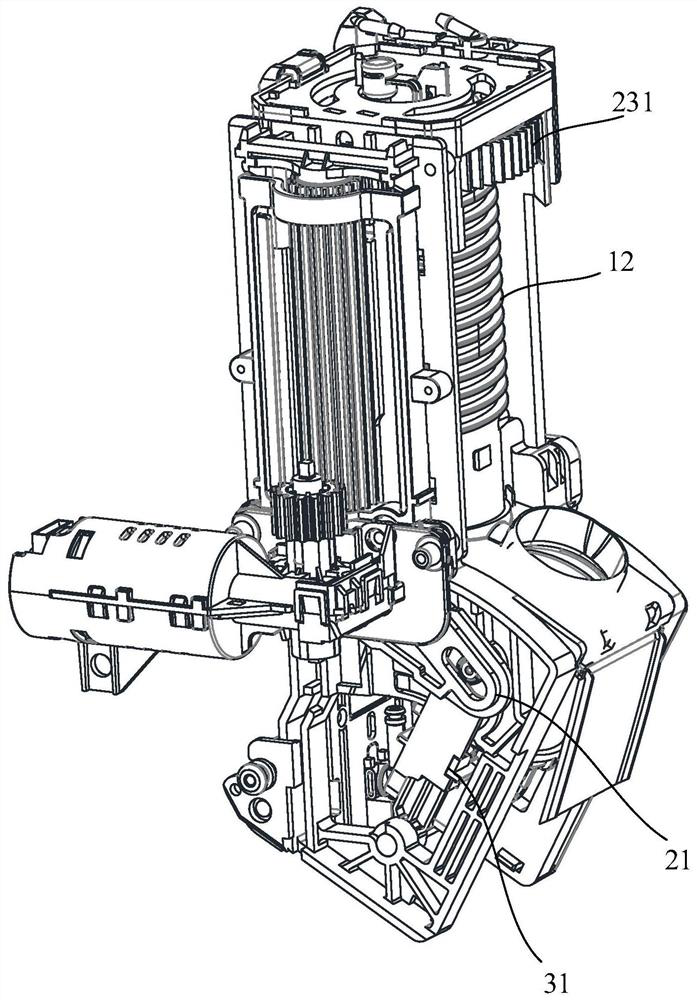

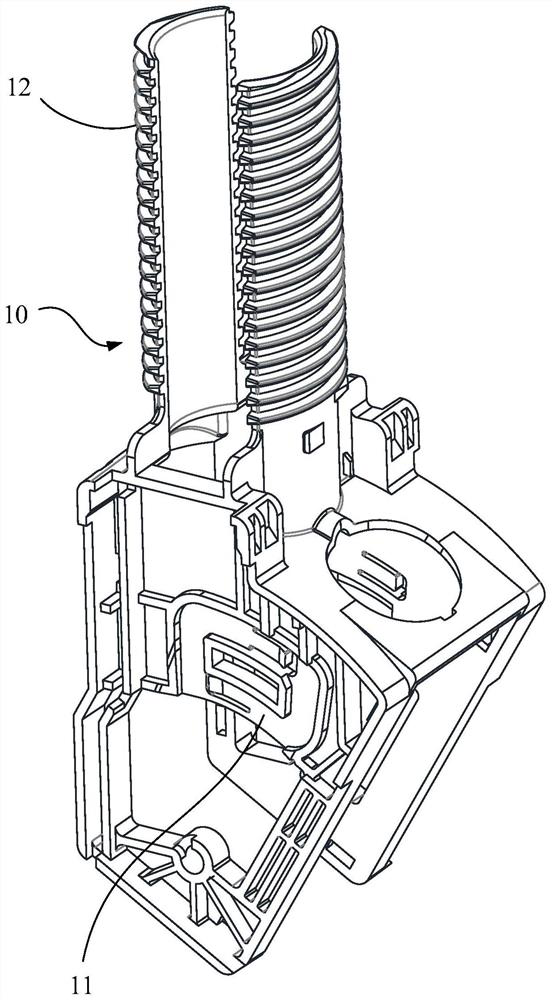

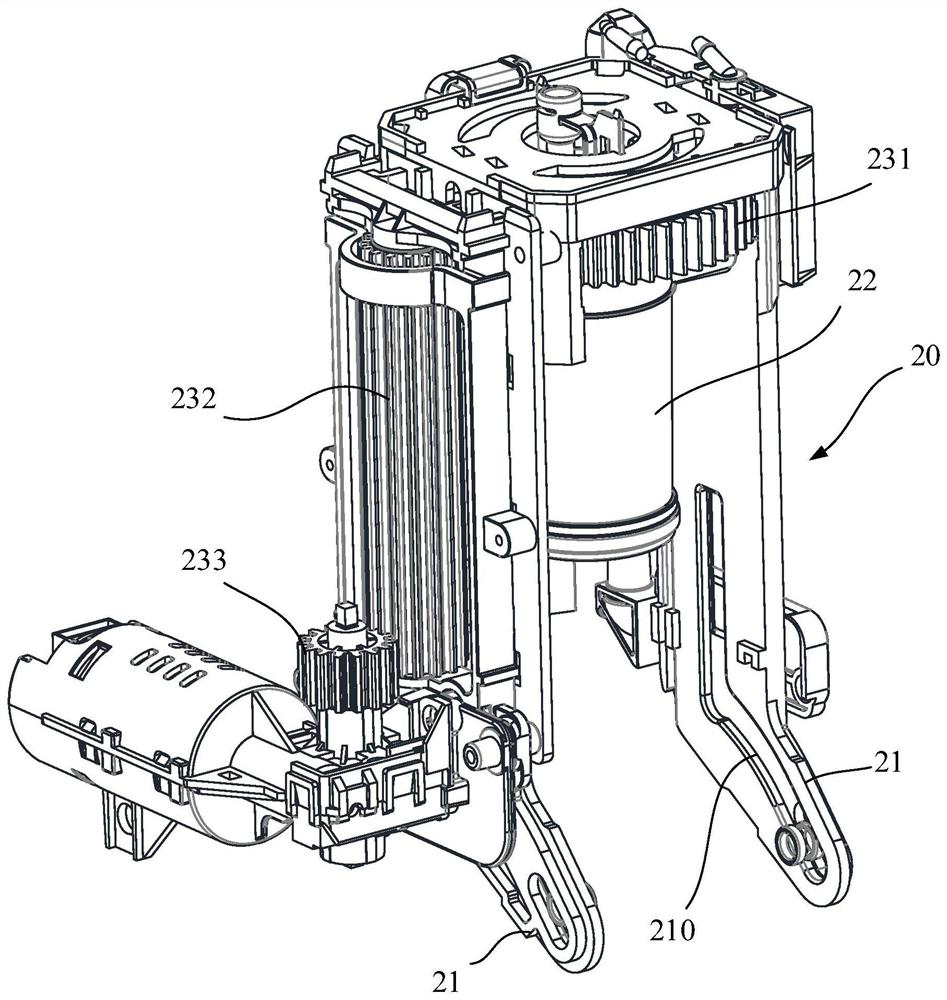

[0036] Such as Figure 1-Figure 11 As shown, the present embodiment discloses a brewing assembly movement mechanism. The brewing assembly movement mechanism includes a brewing unit 20 having an outer track part 21 and a compacting part 22, an accommodating unit 30 and a main body support 10. The brewing unit 20 is relatively The main frame 10 moves up and down, and the accommodating unit 30 rotates relative to the main frame 10 .

[0037] Such as Figure 1-Figure 3 As shown, the main body bracket 10 of this embodiment includes a threaded portion 12 , and the brewing unit 20 further includes a driving gear 233 , a driving gear 232 , and a driving gear 231 . Wherein, the compacting part 22, the outer track part 21 and the driving gear 231 are taken as a whole. The inner thread of the driving gear 231 is engaged with the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com