Method for the optimized movement coordination of measuring machines or machine tools having redundant translatory axes

A translational motion, motion coordination technology, applied in computer control, general control system, control/regulation system, etc., can solve problems such as unsuitable application occasions, realization, maximum speed reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

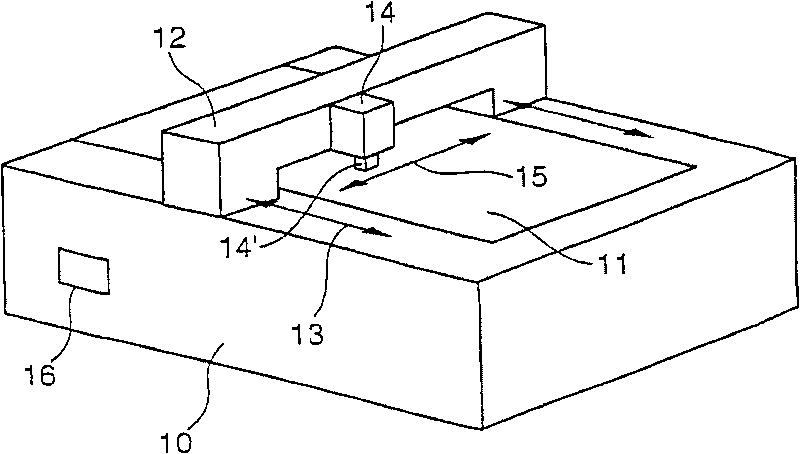

[0058] figure 1 A machine tool 10 is shown in which a workpiece 11 is arranged in a stationary manner. The gantry 12 can move along the axial direction 13 . On this gantry 12, be provided with device 14, be provided with tool holder 14 ' again on this device 14, this tool holder 14 ' can hold cutter. The device 14 (and thus the toolholder 14' together with the tool) is movable in an axial direction 15. The toolholder 14' is also movable relative to the device 14 in the axial direction 13. Depend on figure 1 It can be seen that the toolholder 14' (with the tool) has a lower mass than the device 14, which can be called a slide. The gantry 12 with the associated drive is the first partial shaft acting in the direction 13 and is referred to as the base shaft, while the toolholder 14' with the associated drive is the second partial shaft acting in the axial direction 13, i.e. additional axis. The base axis has a larger range of motion and lower acceleration than the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com