Coupling transmission mechanism of dexterous hand finger joint gear of robot

A transmission mechanism and dexterous hand technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as poor motion coordination, coupling gap, complex structure, etc., to achieve stable motion, improve motion accuracy, and good motion coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

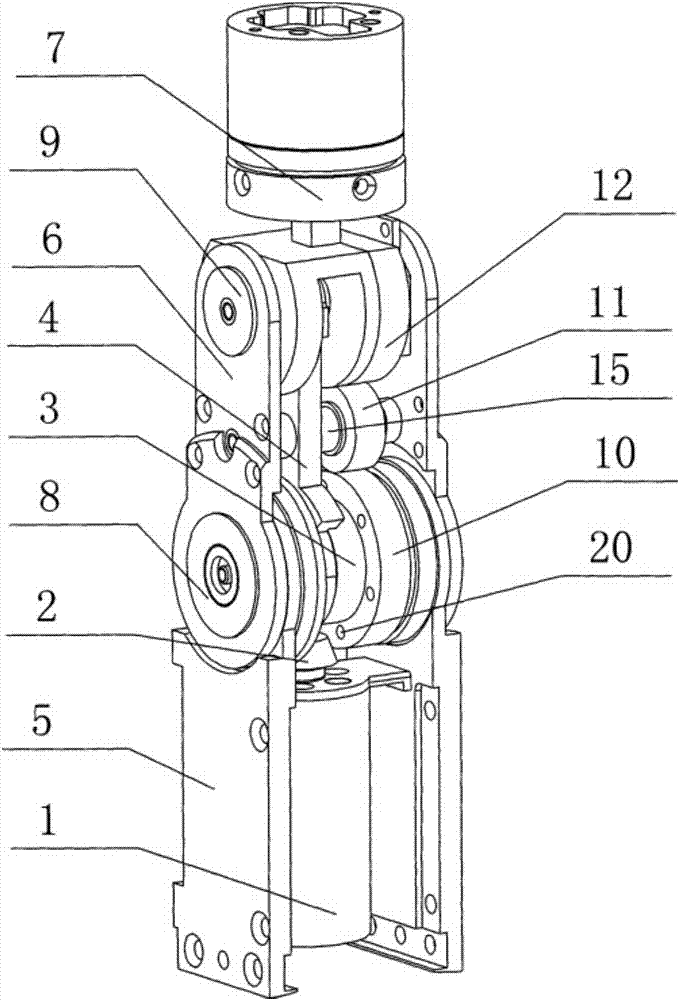

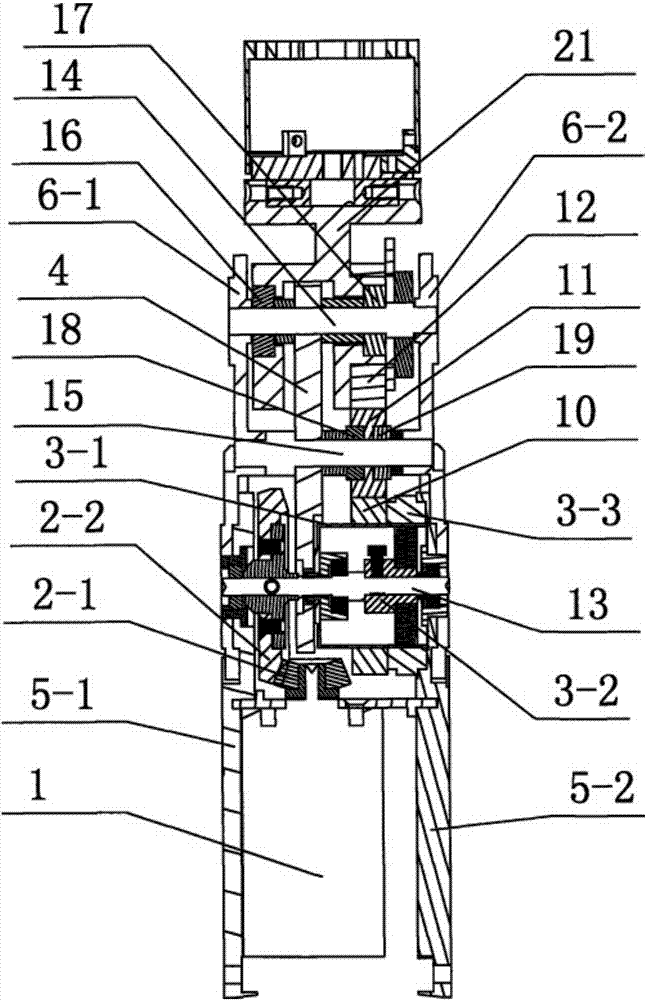

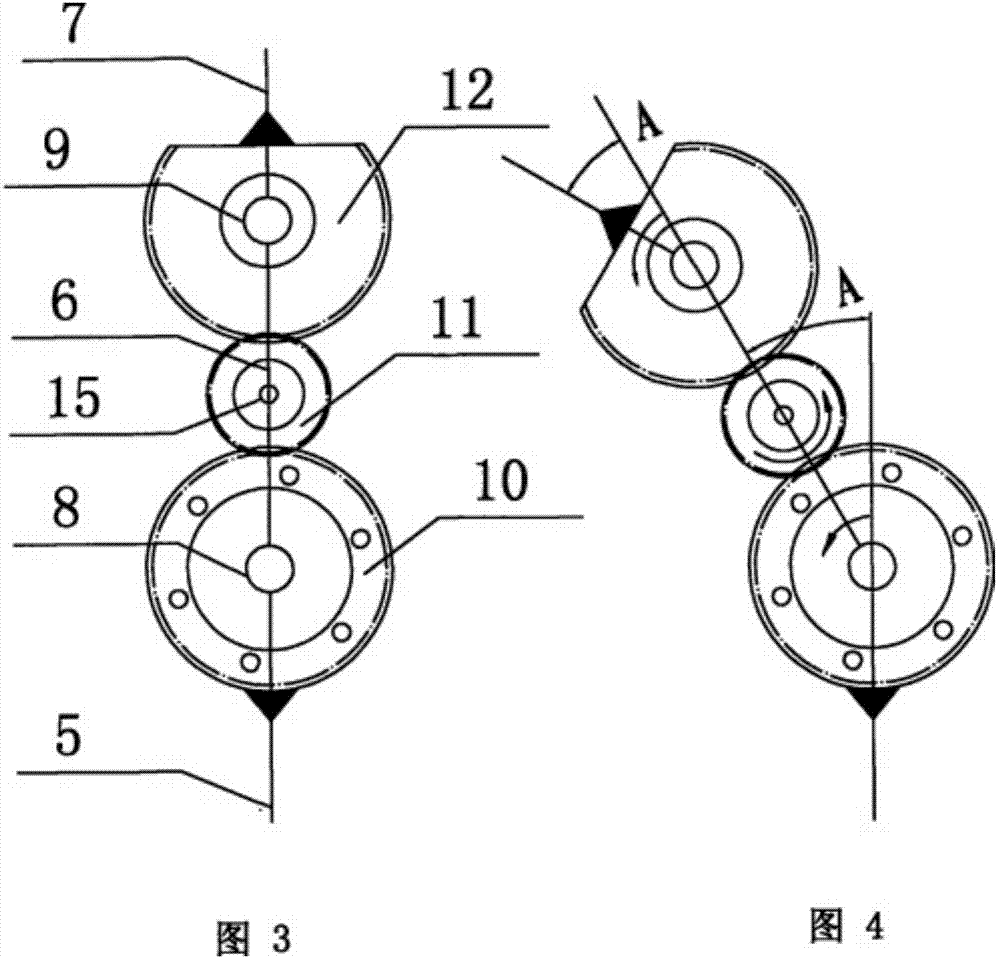

[0008] Specific implementation mode one: as Figure 1~4 As shown, the robot dexterous finger joint gear coupling transmission mechanism described in this embodiment is composed of a fixed spur gear 10, an intermediate gear 11, a driven spur gear 12, and an intermediate gear support shaft 15. The fixed spur gear 10, the intermediate gear 11 has the same modulus as the driven spur gear 12, the fixed spur gear 10 has the same number of teeth as the driven spur gear 12, and the intermediate gear 11 meshes with the fixed spur gear 10 and the driven spur gear 12 respectively; the fixed spur gear 10 is set on On the flexible wheel 3-1 of the harmonic reducer 3, the fixed spur gear 10 is fixed together with the rigid wheel 3-3 of the harmonic reducer 3 and the right side wall 5-2 of the first knuckle, and the fixed spur gear 10 is coaxial with the middle joint 8 (the shaft refers to the middle joint rotation shaft 13), the middle gear support shaft 15 is located in the middle knuckle ...

specific Embodiment approach 2

[0010] Specific implementation mode two: as Figure 1~4 As shown, the axial distance between the fixed spur gear 10 and the intermediate gear 11 in this embodiment is the same as the axial distance between the driven spur gear 12 and the intermediate gear 11 , which is equal to 1 / 2 of the length of the middle knuckle 6 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: as Figure 1~4 As shown, this embodiment is an embodiment in which the finger joint gear coupling transmission mechanism of the present invention is installed in the finger of a robot dexterous hand:

[0012] The robot dexterous hand finger after installing the present invention mainly comprises gear coupling transmission mechanism (the present invention), first knuckle 5, middle knuckle 6, terminal knuckle 7, middle joint 8, terminal joint 9, driving motor 1, transmission umbrella Gear pair 2, harmonic reducer 3, middle knuckle transmission part 4, fingertip one-dimensional torque sensor 21, described transmission bevel gear pair 2 is made up of small transmission bevel gear 2-1 and large transmission bevel gear 2-2, Described gear coupling transmission mechanism is made up of fixed spur gear 10, intermediate gear 11, driven spur gear 12, intermediate gear support shaft 15, and the module of described fixed spur gear 10, intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com