A grinding device for thread cutter tooth profile

A thread cutter and tooth profile technology, applied in the field of grinding and online measurement of tooth profile, can solve the problems of poor consistency of bolt fatigue strength, time-consuming and labor-intensive, unfavorable production, etc., and achieves good motion coordination, simple structure, improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

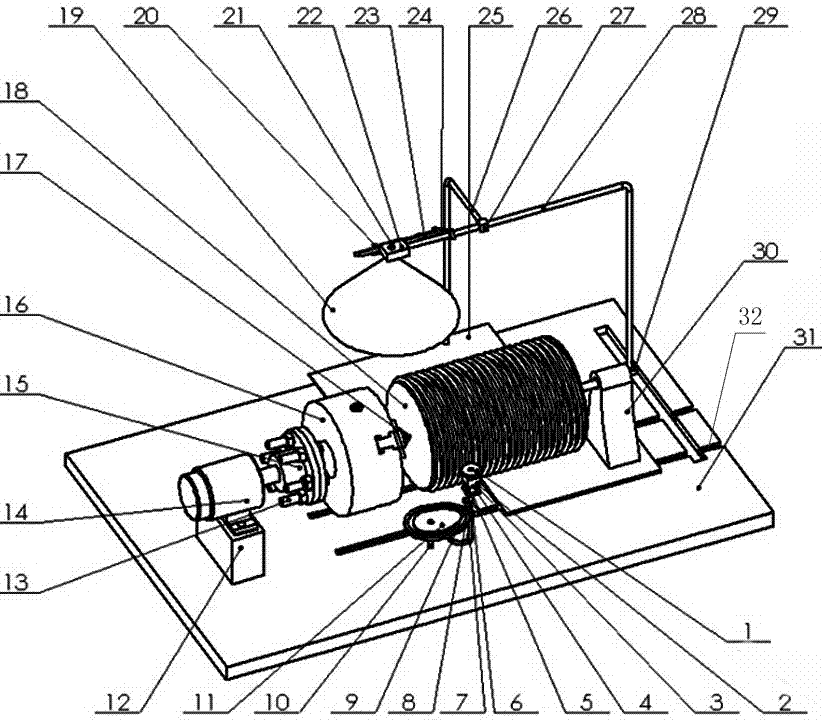

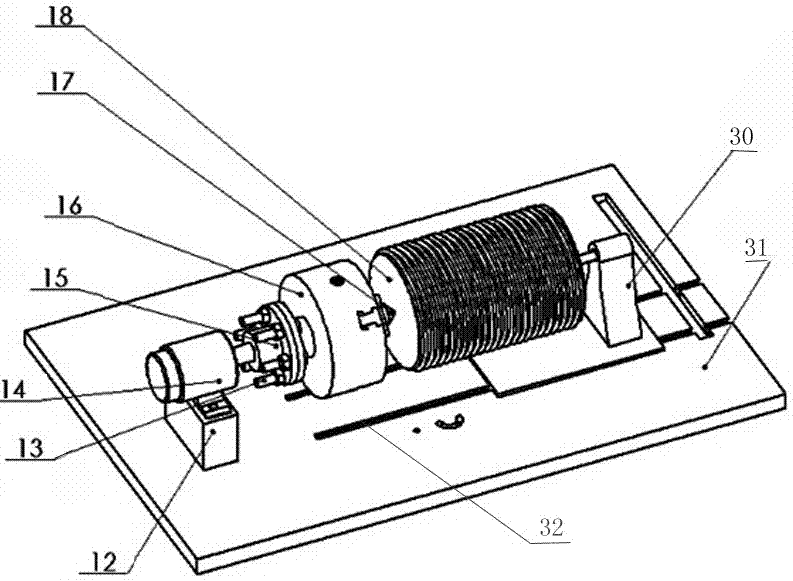

[0020] The invention is attached Figure 1-4 for further clarification.

[0021] A grinding device for tooth profiles of thread cutters, the device includes a working platform 31, a chute 32 is provided on the working platform 31, a power clamping mechanism and a tooth profile grinding mechanism are also provided on the working platform 31,

[0022] Wherein the power clamping mechanism includes a support 30 on the working platform 31, and the corresponding support 30 is provided with a rotating motor 14 at the other end of the working platform 31. The rotating motor 14 is erected on the spacer 12, and the rotating motor 14 is fixed by bolts 13. There is a coupling 15, the front end of the coupling 15 is provided with a chuck 16 and a top 17, and a thread cutter 18 is clamped between the support 30 and the top 17;

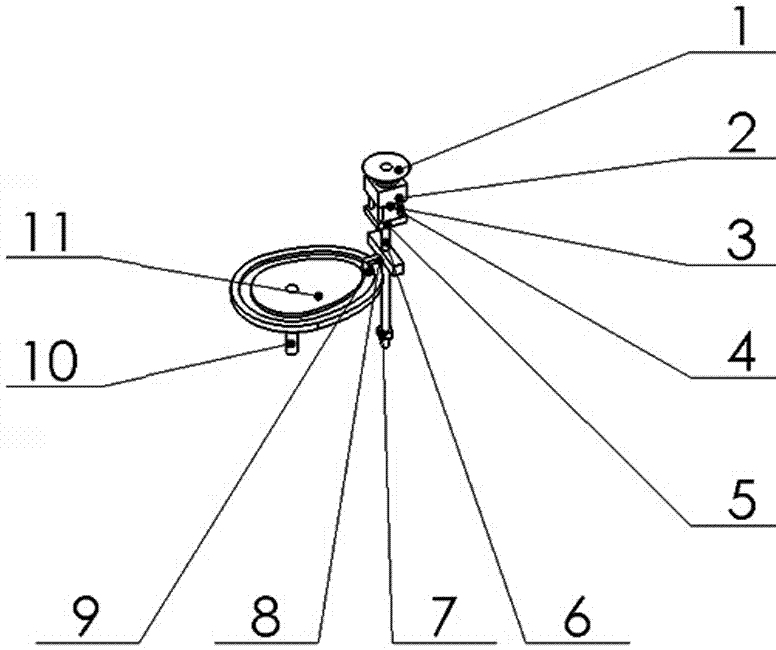

[0023] The tooth shape grinding mechanism includes a grinding wheel 1. During operation, the grinding wheel 1 is tangent to the outer circle of the thread cutter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com