Six degrees of freedom permanent magnet synchronous magnetic suspension spherical motor

A permanent magnet synchronous, spherical motor technology, used in synchronous motors with rotating armatures and stationary magnets, electrical components, holding devices with magnetic attraction or thrust, etc. Complex structure and other problems, to achieve the effect of compact structure and high-precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

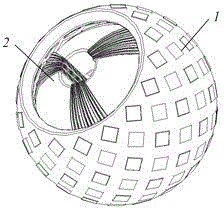

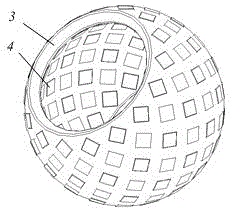

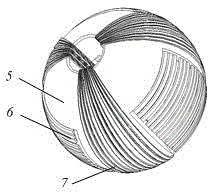

[0016] A six-degree-of-freedom permanent magnet synchronous magnetic levitation spherical motor, including: a spherical shell-shaped stator 1 and a spherical mover 2; wherein the spherical shell-shaped stator 1 includes: a stator shell 3 and a magnetic steel 4, and the spherical mover 2 includes: a mover ball Core 5, horizontal coil 6 and vertical coil 7.

[0017] The stator shell 3 is a hollow spherical shell with an inner diameter of 100 mm and an outer diameter of 118 mm, and the north and south poles of the stator shell 3 have a hollowed-out cross section. The magnetic steel 4 is a cube with a side length of 18 mm. Magnets, the magnetized surface of the magnetic steel 4 is perpendicular to the radius of the stator shell 3, and is distributed orthogonally along the latitude and longitude of the stator shell 3, forming a spherical two-dimensional NS type magnetic steel array with a pole pitch of 19.5mm, embedded in the stator shell 3.

[0018] The mover core 5 is spherical, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com