Torque control strategy for three degree-of-freedom permanent magnet spherical motor

A spherical motor, torque control technology, applied in motor generator control, AC motor control, electronic commutation motor control and other directions, can solve the problem of inability to reduce operation time, avoid stator current, simplify structure, reduce Effects of Torque Ripple Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

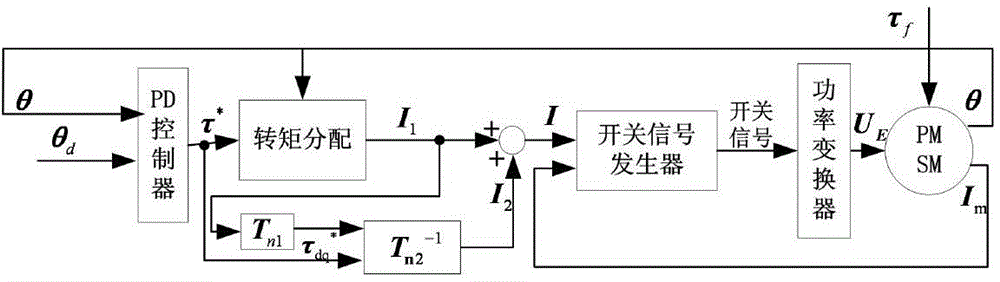

[0043] The invention is a new torque distribution control strategy proposed for a new type of permanent magnet spherical motor, which can improve the calculation time of the stator control current when realizing the decoupling control of the motor's self-rotating motion and tilting motion and reducing torque ripple.

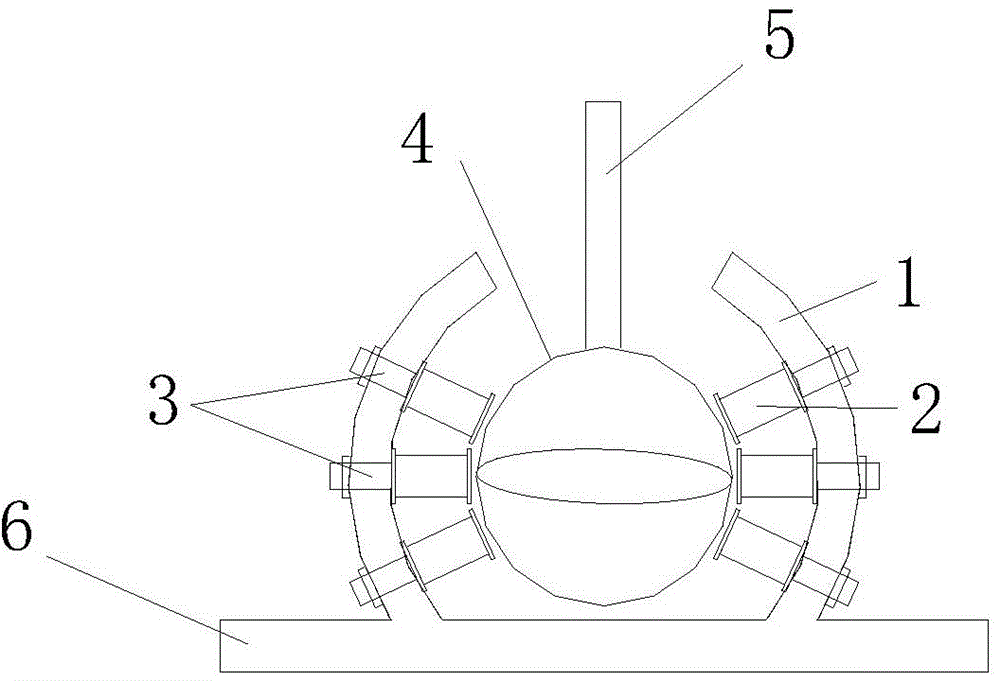

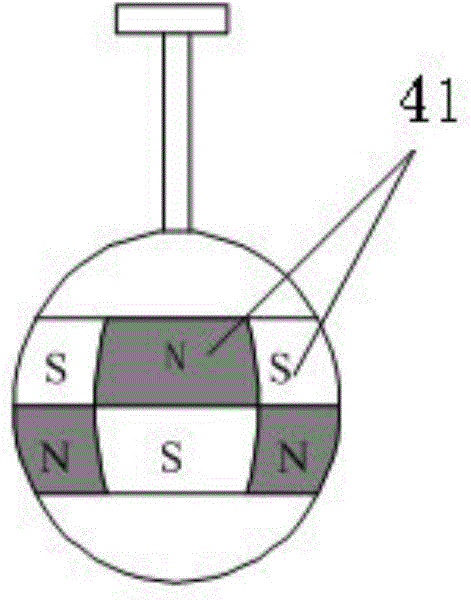

[0044] The basic structure of the motor is shown in Figure 1. The three-degree-of-freedom permanent magnet spherical motor applicable to the present invention includes four parts: a support part, a stator and a spherical rotor sensor, wherein the support part includes a stator wall 1, a base 6, and the stator includes a hollow coil 2, coil bolts (3), and a spherical rotor 4 The output shaft 5 is fixed on the top, the rotor 4 is located in the stator wall 1, and the rotor output shaft 5 protrudes from the opening above the stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com