A preparation method of molybdenum disulfide microcapsules, positive electrode of magnesium ion battery, magnesium ion battery

A magnesium ion battery, molybdenum disulfide technology, applied in the direction of molybdenum sulfide, battery electrodes, secondary batteries, etc., can solve the problems of poor conductivity and low loading of microcapsules, achieve high reproducibility, improve conductivity, and improve The effect of cycle capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A preparation method for molybdenum disulfide microcapsules, comprising the following steps:

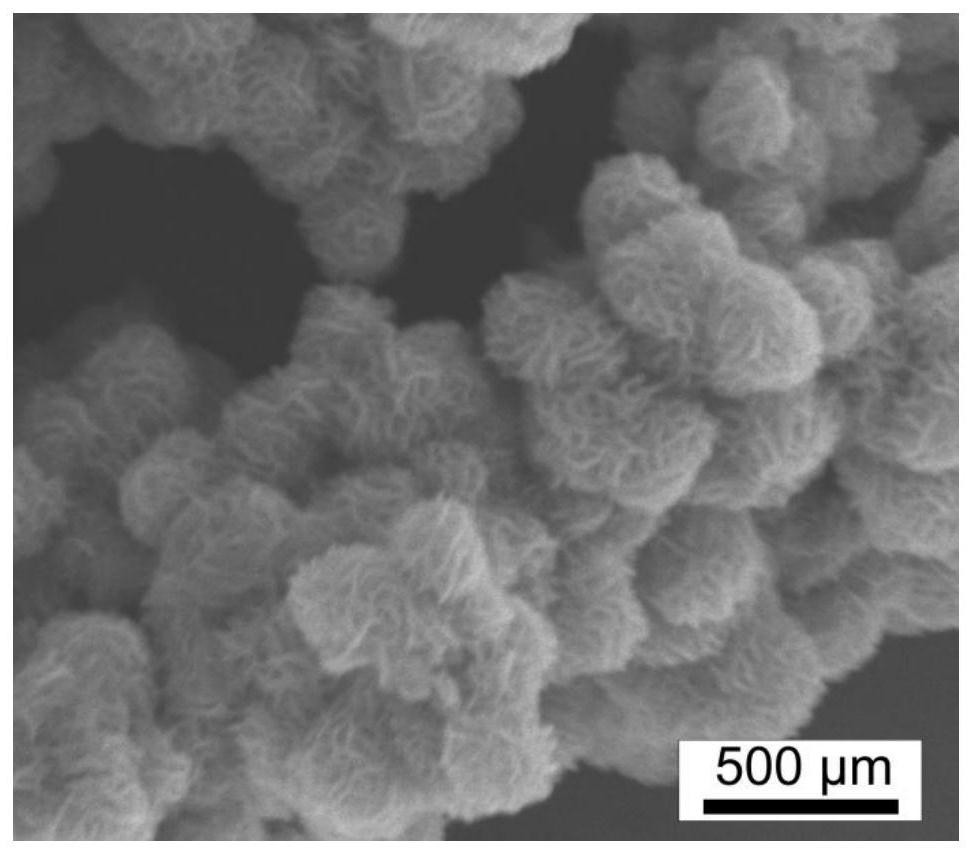

[0057] (1) Hydrothermal process: Weigh 0.9g of ammonium molybdate tetrahydrate and 1.0g of thioacetamide dissolved in 30mL of deionized water, then add 0.5g of polyethylene glycol 750 monomethyl ether to the above solution, and continue to stir for 1h Then transfer to a 50mL polytetrafluoroethylene reactor and put it into an oven at 160°C for 24h. Naturally cooled to room temperature, deionized H 2 O was washed several times by centrifugation, and the precipitated product was collected. Its SEM picture is as follows figure 1 As shown, it can be seen from the figure that it is a nanosphere self-assembled by nanosheets, with a size of 500nm. Take 200mg of the product and ultrasonically disperse it in 10mL of 2wt% polyvinyl alcohol aqueous solution to obtain MoS with a concentration of 20mg / mL 2 solution.

[0058] (2) 0.2g photoinitiator 2-hydroxyl-2-methylpropiophenone is m...

Embodiment 2

[0062] A preparation method for molybdenum disulfide microcapsules, comprising the following steps:

[0063] (1) Hydrothermal process: Weigh 0.8g of ammonium molybdate tetrahydrate and 0.7g of thioacetamide and dissolve them in 30mL of deionized water, then add 0.5g of polyethylene glycol 750 monomethyl ether to the above solution, and continue stirring for 1h Then transfer to a 50mL polytetrafluoroethylene reactor and put it into an oven at 160°C for 24h. Naturally cooled to room temperature, deionized H 2 O was washed several times by centrifugation, and the precipitated product was collected. Take 200mg of the product and ultrasonically disperse it in 10mL of 2wt% polyvinyl alcohol aqueous solution to obtain MoS with a concentration of 20mg / mL 2 solution;

[0064] (2) Mix 0.4g photoinitiator 2-hydroxyl-2-methylpropiophenone with 20g organic photocurable material ETPTA to obtain a mixed solution A with a photoinitiator content of 2%;

[0065] (3) Using liquid flooding co...

Embodiment 3

[0068] A preparation method for molybdenum disulfide microcapsules, comprising the following steps:

[0069] (1) Hydrothermal process: Weigh 0.8g of ammonium molybdate tetrahydrate and 0.7g of thioacetamide and dissolve them in 30mL of deionized water, then add 0.5g of polyethylene glycol 750 monomethyl ether to the above solution, and continue stirring for 1h Then transfer to a 50mL polytetrafluoroethylene reactor and put it into an oven at 160°C for 24h. Naturally cooled to room temperature, deionized H 2 O was washed several times by centrifugation, and the precipitated product was collected. Take 800mg of the product and ultrasonically disperse it in 10mL of 2wt% polyvinyl alcohol aqueous solution to obtain MoS with a concentration of 80mg / mL 2 solution;

[0070] (2) 0.6g photoinitiator 2-hydroxyl-2-methylpropiophenone is mixed with 20g organic photocurable material ETPTA to obtain a mixed solution A in which the quality of photoinitiator is 3% of the organic photocurab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com