3D printing system and method for controlling size of molten pool formed during printing process

A technology of printing process and printing system, which is applied in the direction of manufacturing tools, additive manufacturing, energy efficiency improvement, etc., can solve the problem of not developing real-time control of molten pool, etc., and achieve the effect of improving quality and process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present disclosure will be described in detail with reference to the accompanying drawings. The present disclosure can be implemented in various forms and is not limited to the embodiments described here. In the drawings, in order to clearly describe the present disclosure, parts irrelevant to the description are omitted, and the same reference numerals designate the same or similar elements throughout the specification.

[0039] A 3D printing system according to an embodiment of the present disclosure is a system capable of melting a substrate using a laser to form a three-dimensional object, and also estimating the temperature of a melted melt pool during 3D printing in real time. In this case, the 3D printing system according to an embodiment of the present disclosure may be a DED type 3D printing system capable of forming a 3D object by melting metal powder or metal wire with a laser.

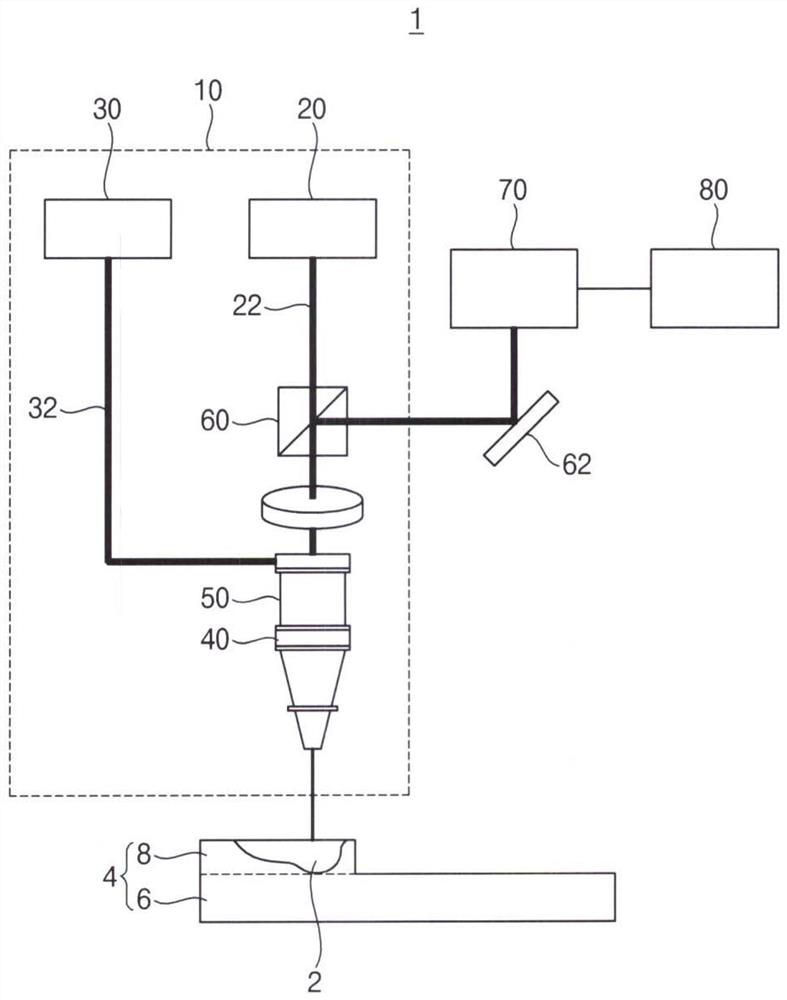

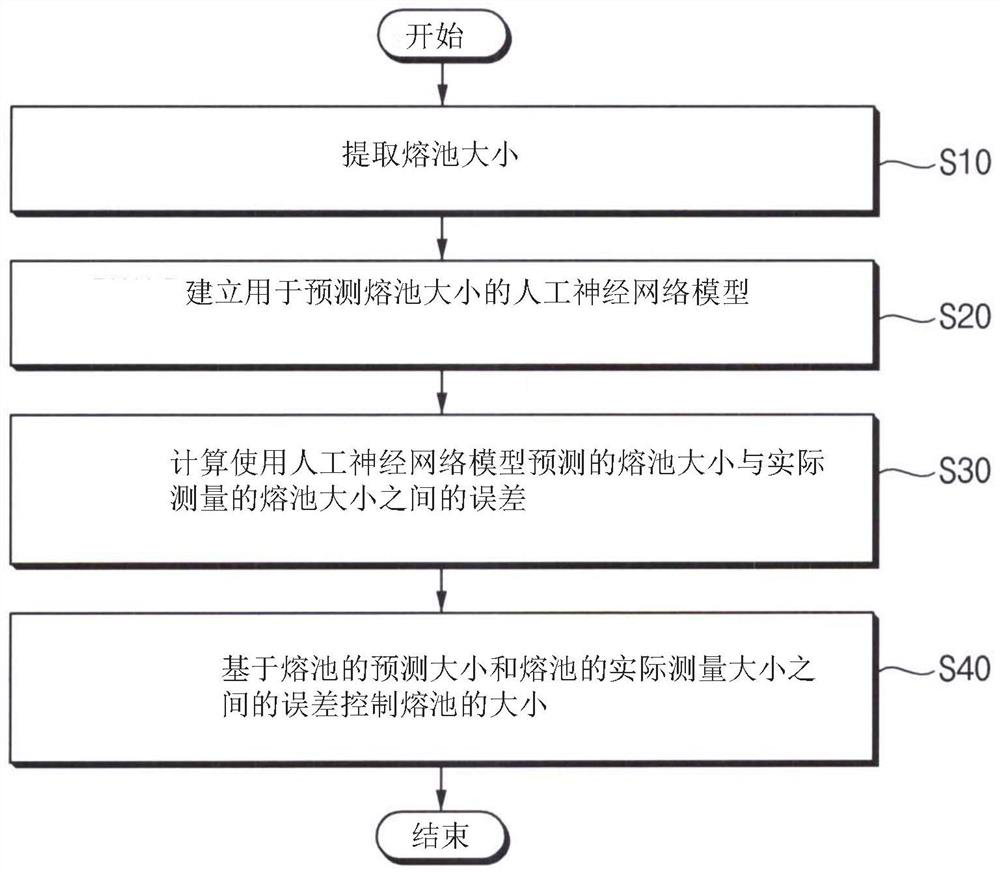

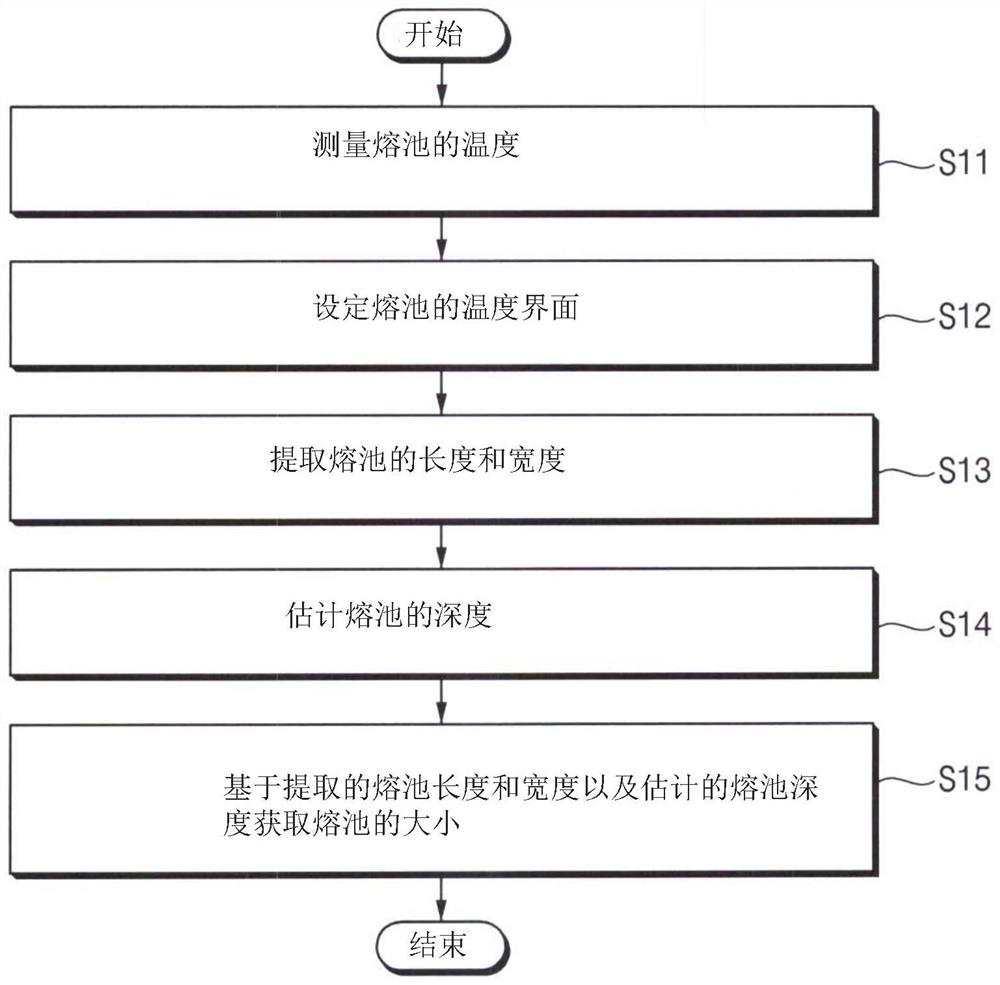

[0040] figure 1 A configuration of a 3D printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com