Cambered surface type two-degree-of-freedom permanent magnet in-wheel motor

A technology of in-wheel motors and degrees of freedom, applied in motors, synchronous motors with stationary armatures and rotating magnets, electric vehicles, etc., can solve problems such as occupancy, large vehicle space, and increased vehicle unsprung mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

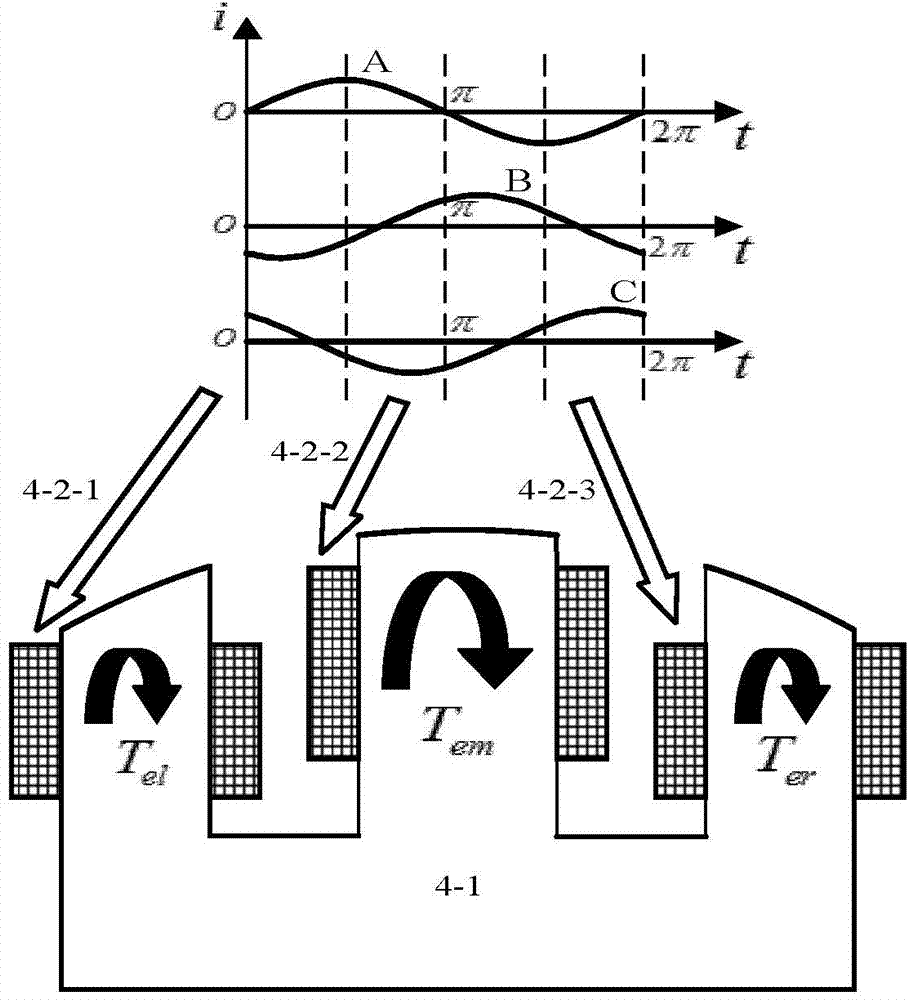

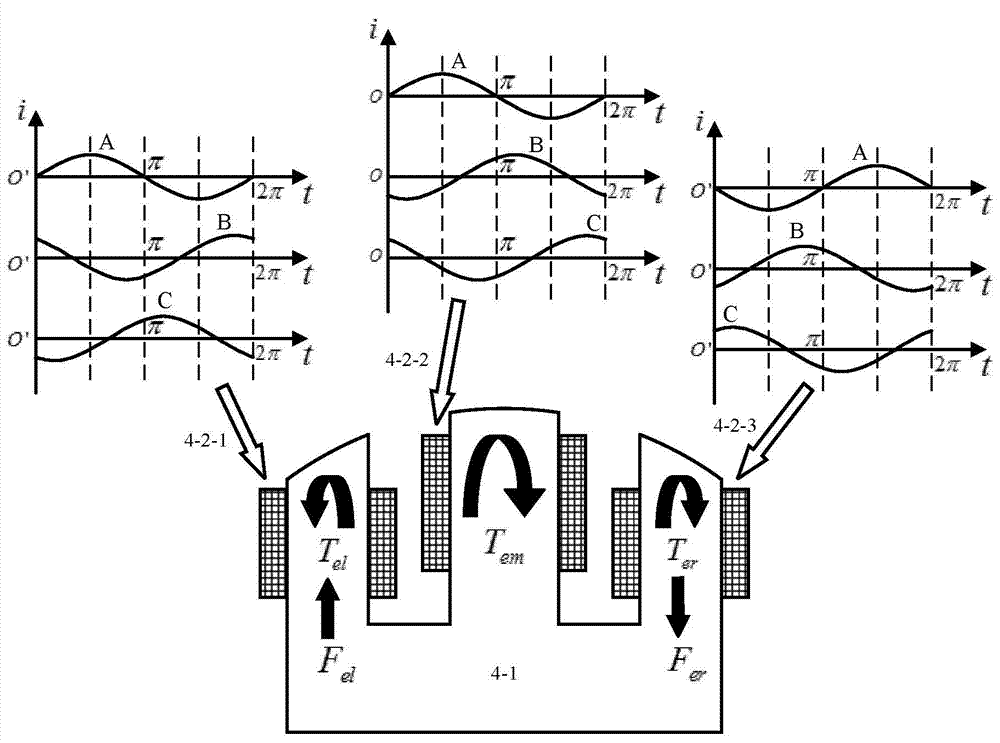

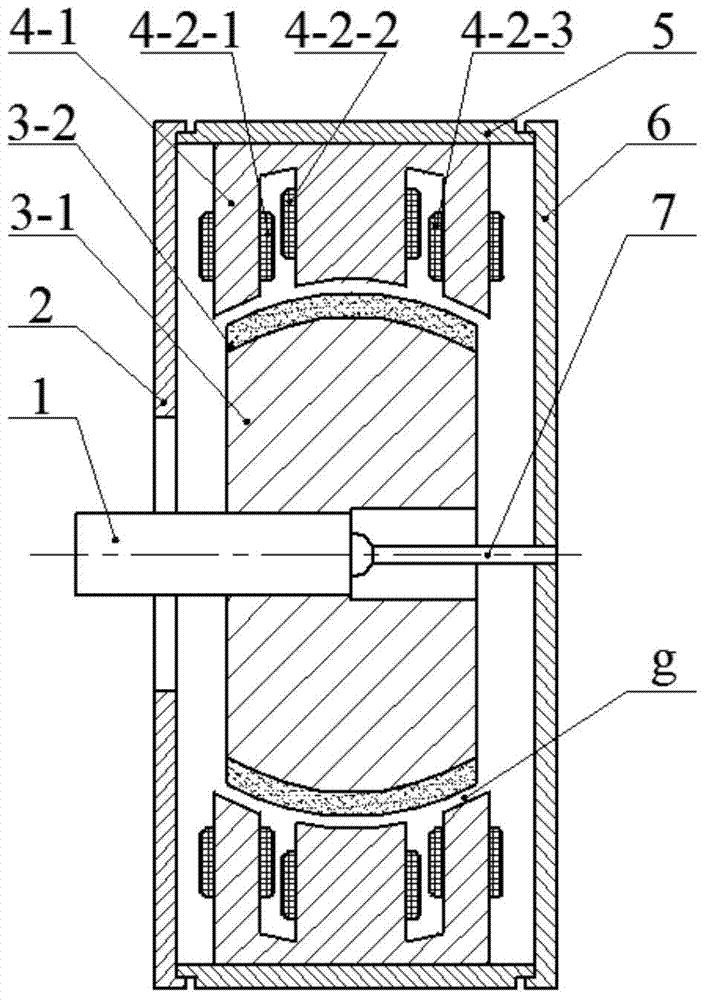

[0025] Specific implementation mode 1, refer to Figure 3 to Figure 9 Describe this embodiment in detail, the arc surface two-degree-of-freedom permanent magnet hub motor described in this embodiment includes a rotor, a stator, a shaft 1, a left end cover 2, a housing 5, a right end cover 6 and a bearing 7; the rotor includes a rotor iron Core 3-1 and permanent magnet 3-2, the stator includes stator iron core 4-1 and stator winding 4-2; stator winding 4-2 includes left yaw winding 4-2-1, drive winding 4-2-2 and Right swing winding 4-2-3;

[0026] The two end faces of the housing 5 are respectively provided with a left end cover 2 and a right end cover 6, the left end of the shaft 1 protrudes from the left end cover 2, and the right end of the shaft 1 is movably connected with the right end cover 6 through a bearing 7;

[0027] The rotor or stator is fixed on the shaft 1, and the inner wall of the housing 5 is correspondingly provided with a stator or rotor; and there is a uni...

specific Embodiment approach 2

[0029] Specific embodiment 2. This specific embodiment is a further description of the arc surface two-degree-of-freedom permanent magnet hub motor described in specific embodiment 1. In this embodiment, the stator core 4-1 is divided into three parts along the axial direction. Each part is configured with an armature winding, wherein the middle part is configured with a drive winding 4-2-2, and the parts on both sides are respectively configured with a left yaw winding 4-2-1 and a right yaw winding 4-2-3.

specific Embodiment approach 3

[0030] Specific embodiment three. This specific embodiment is a further description of the arc surface two-degree-of-freedom permanent magnet hub motor described in specific embodiment two. In this embodiment, the left yaw winding 4-2-1, the drive winding 4- 2-2 and the right swing winding 4-2-3 have the same equivalent number of poles of the exciting magnetic field, and both are realized by adopting concentrated winding or distributed winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com