Damaged film gathering method

A technology for picking up residual film and residual film, which is applied in the direction of applications, collectors, agricultural machinery and implements, etc., can solve the problems of residual film winding and failure to solve, and achieve high work reliability, good film picking performance and simplified process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

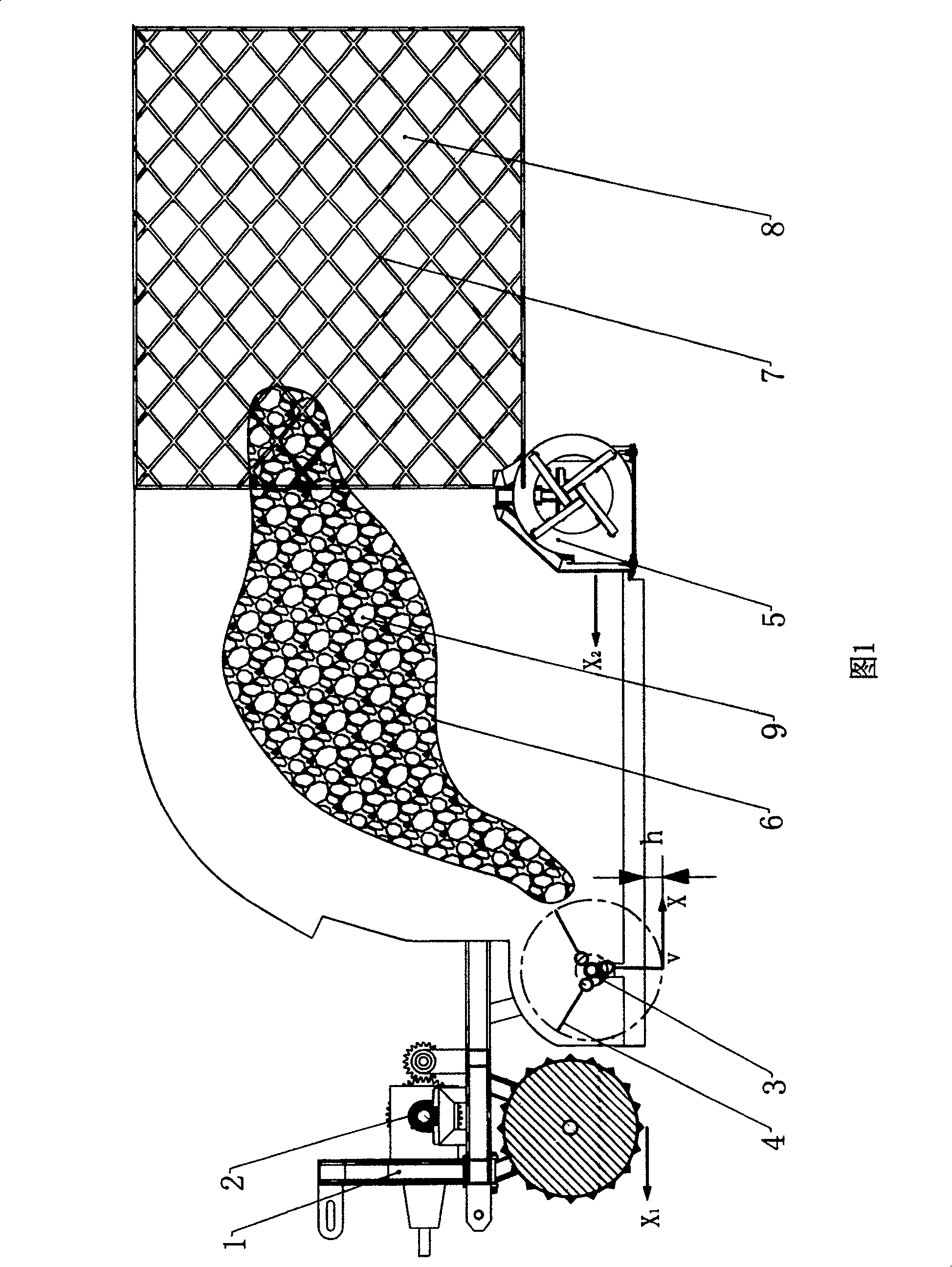

[0021] Example: A method for picking up residual film

[0022] Including the following steps:

[0023] (1), film picking: driven by the transmission mechanism 2 installed on the frame 1, the film picking device 3 with a higher speed drives the three rows of spring teeth 4 arranged on the film picking device, and the diameter of the spring teeth is 5 mm , when the spring tooth 4 enters the soil and is perpendicular to the ground, the linear velocity direction X at the top of the spring tooth and the forward direction X of the film picker 1 On the contrary, the linear velocity v=25 m / s at the top of the spring teeth, the depth of the spring teeth h=5 to 10 cm, most of the residues in the soil will be dislodged by the deformation of the spring teeth and its high linear velocity during work. The membrane is lifted into the air to achieve the separation between the membrane and the soil;

[0024] (2) Film collection: The fan 5 at a distance of 1.0 meters from the film picking dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com