Magnetic levitation spherical motor

A magnetic levitation and spherical motor technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of inability to achieve 360-degree travel, reduce the flexibility of the robot, and limit the rotation angle, and achieve rapid response, simple structure, and convenient steering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

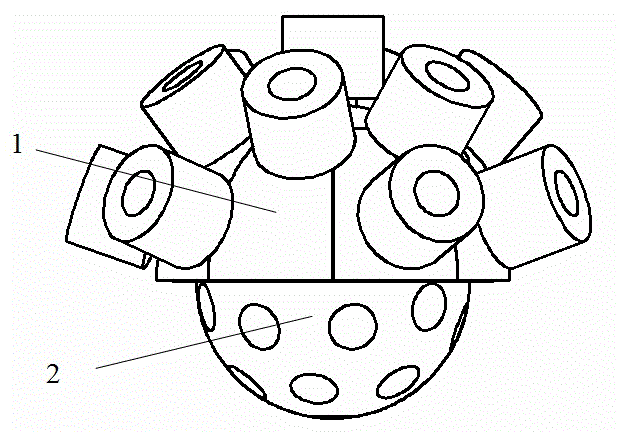

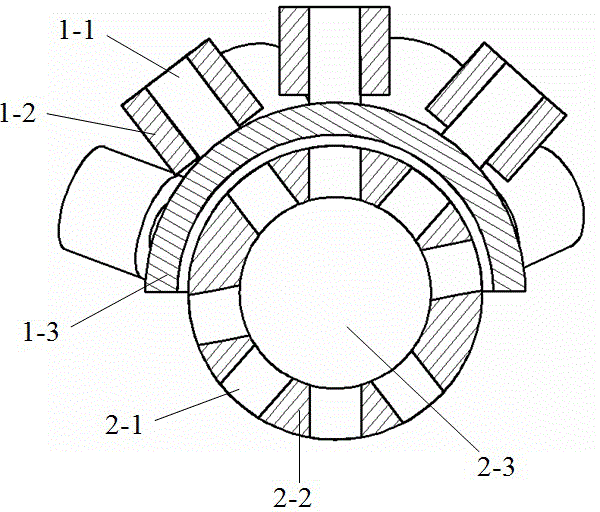

[0026] As shown in the figure, the main embodiment of a spherical motor of the present invention is mainly composed of a stator 1 and a mover 2 matched therewith.

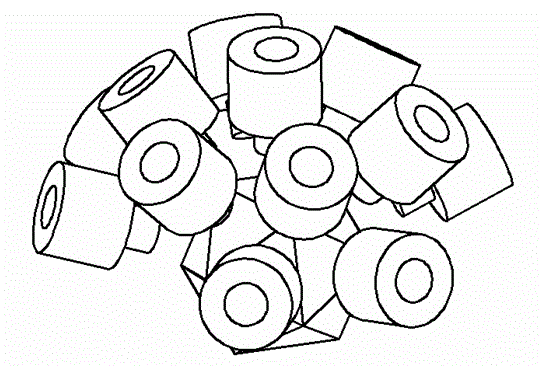

[0027] The mover 2 is a sphere, and the permanent magnet 2-1 is distributed in the sphere of the mover 2. The distribution method is: distributed on all surfaces of the icosahedron 0, and the assembly direction of the magnetic poles points to the center of the mover 2. This The specific embodiment takes the icosahedron as an example, but it is not limited to the icosahedron, and other regular polyhedrons are also applicable. The material of the permanent magnet 2-1 is a rare earth NdFeB permanent magnet. The permanent magnet 2-1 is fixed on the support body 2-3 made of a spherical aluminum plate, and the filling material 2-2 fills the space between the permanent magnet and the support body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com