Artificial hollow micro-nano motor and preparation method thereof

A micro-nano, hollow technology, applied in welding equipment, manufacturing tools, micro-structure technology and other directions, can solve problems such as poor loadability, achieve good load function, facilitate mass production, and have wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

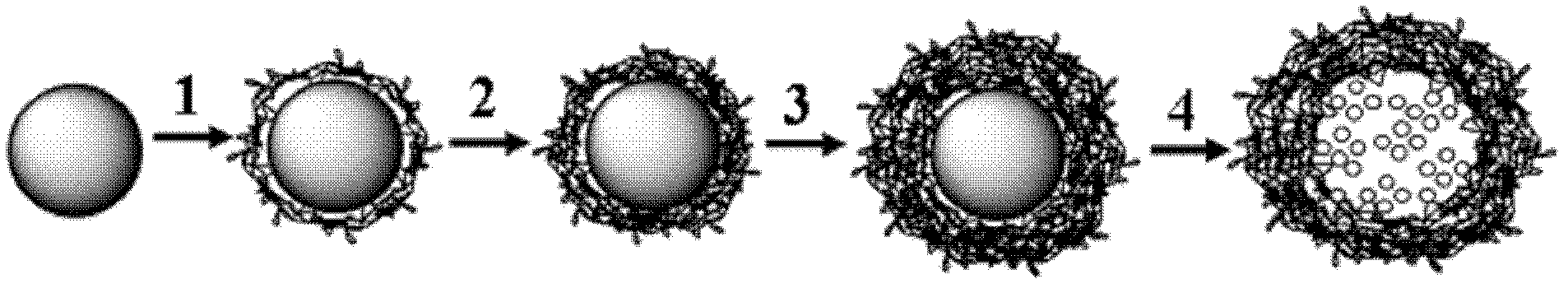

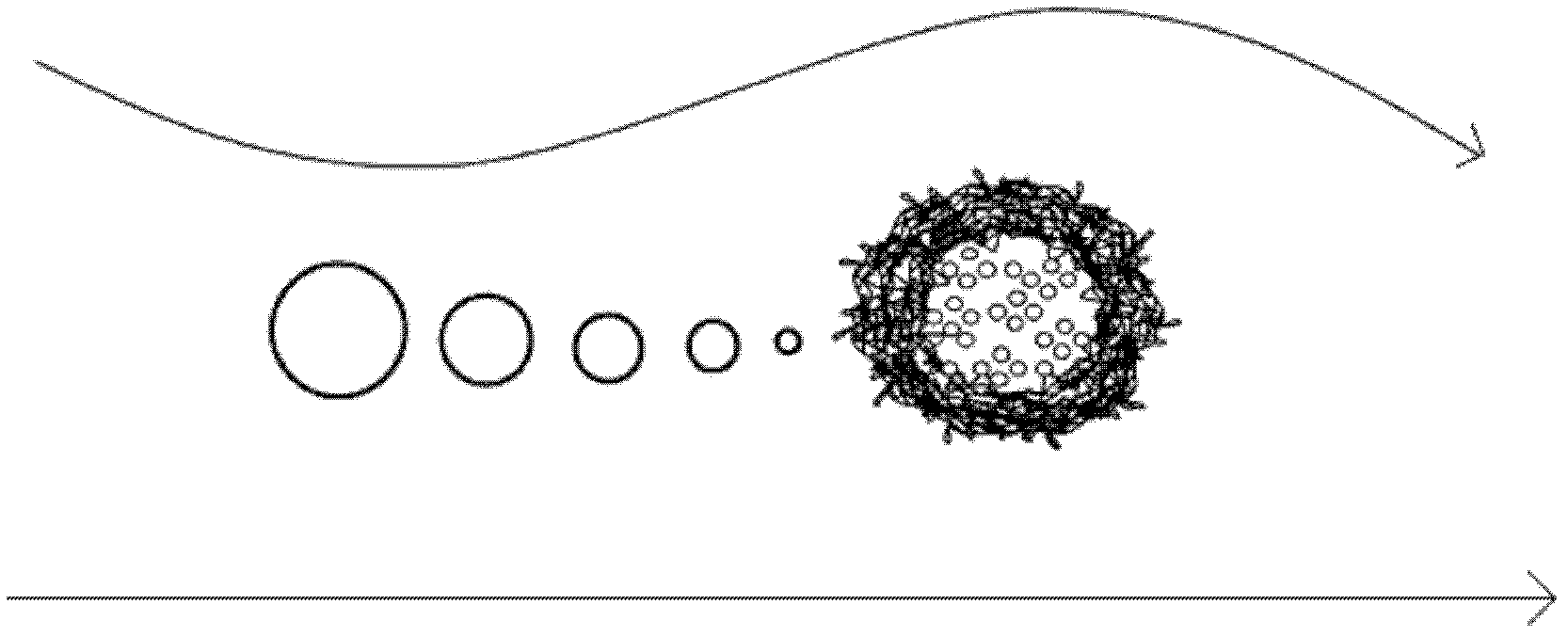

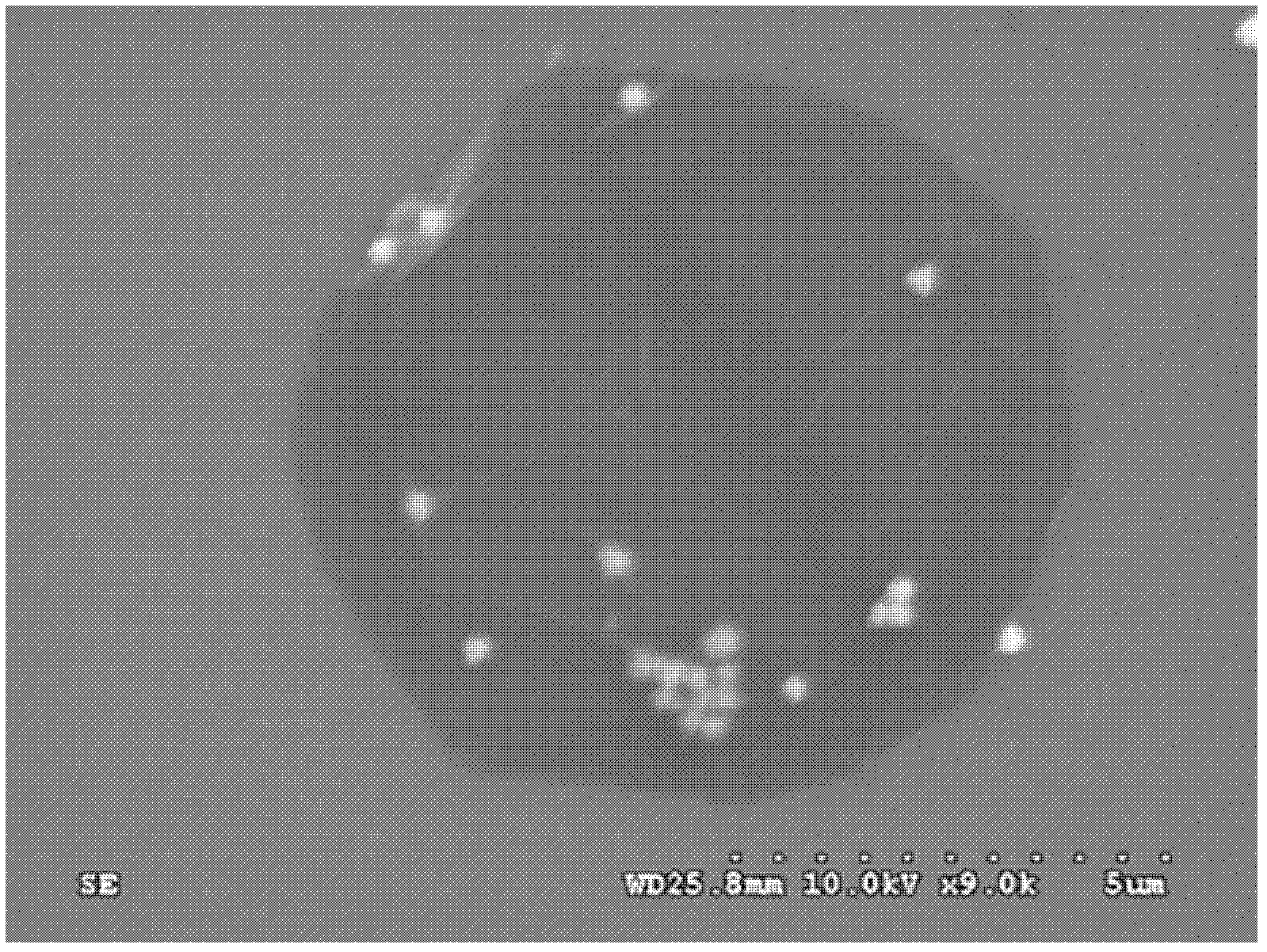

[0029] Specific Embodiment 1: In this embodiment, the artificial hollow micro-nano motor is composed of a hollow sac-shaped skeleton formed by 1 to 10 polyelectrolyte bilayers and micro-nano catalyst particles located in the capsule formed by the skeleton. The diameter of the capsule is 300nm-1000μm, and the particle diameter of the nano-catalyst particles is 3nm-60nm.

[0030] The artificial hollow micro-nano motor of this embodiment not only has good transportability, but also has a good load function, and has broad application prospects in the field of biomedicine, especially in drug release control, blood purification and clinical diagnosis.

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the micro-nano catalyst particles are platinum particles, gold particles, silver chloride particles or catalase. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the polyelectrolyte double layer is made up of cationic polyelectrolyte and anionic polyelectrolyte, wherein cationic polyelectrolyte is polyallylamine hydrochloride (PAH ), polyethyleneimine (PEI), polydimethyldiallylammonium chloride (PDADMAC), chitosan (CS), polyvinylamine (PVAM) or polylysine (PL); anionic poly The electrolyte is sodium polystyrene sulfonate (PSS), polyacrylic acid (PAA), polyglutamic acid (PGA), sodium alginate (SA), or deoxyribonucleic acid (DNA). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com