Spherical motor

A spherical, spherical center technology, applied in the field of electric vehicles, can solve the problem that the in-wheel motor cannot meet the use of occasions with high energy conversion efficiency, and achieve the effect of being conducive to heat dissipation, high energy conversion rate, and good heat dissipation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

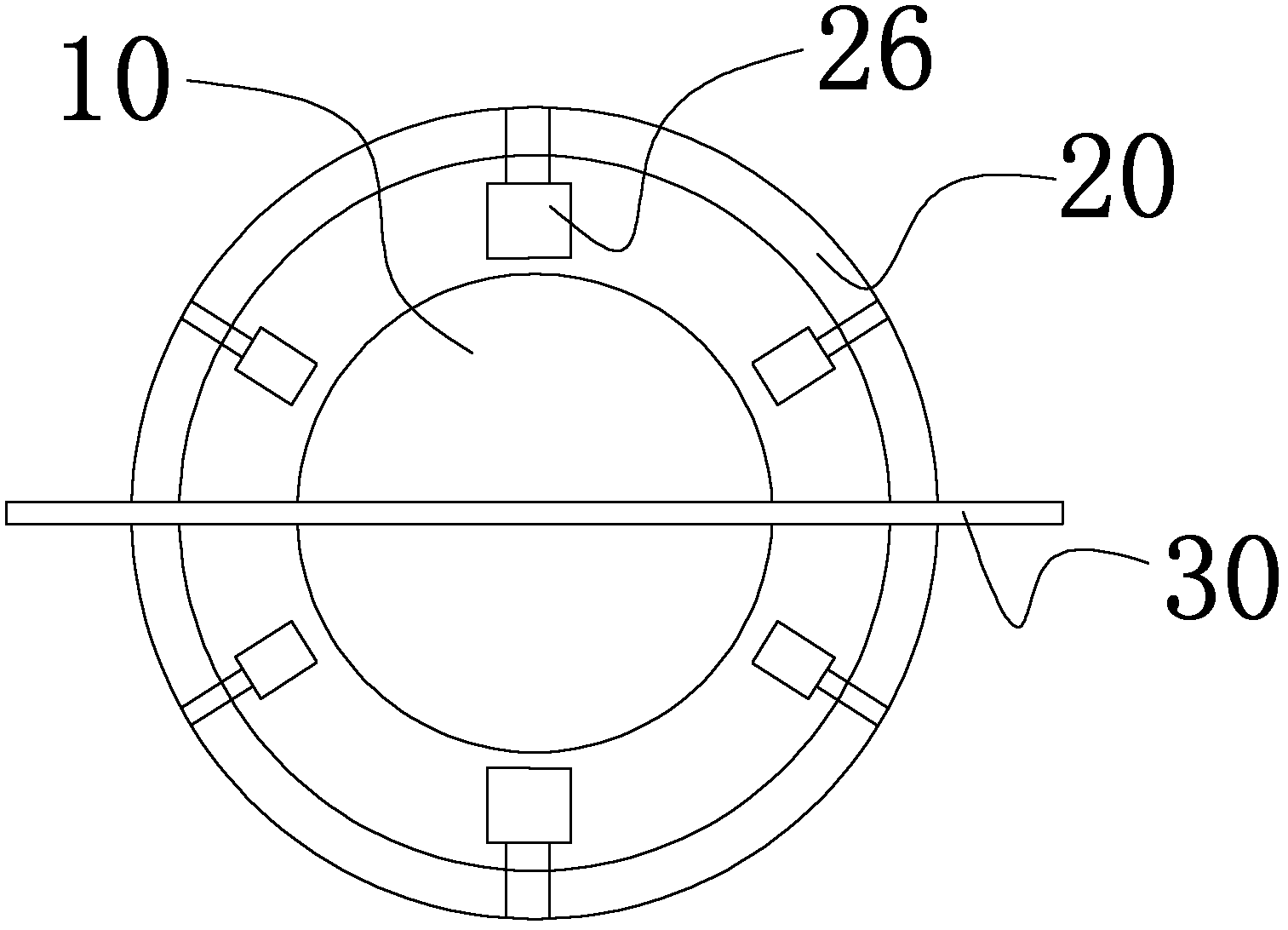

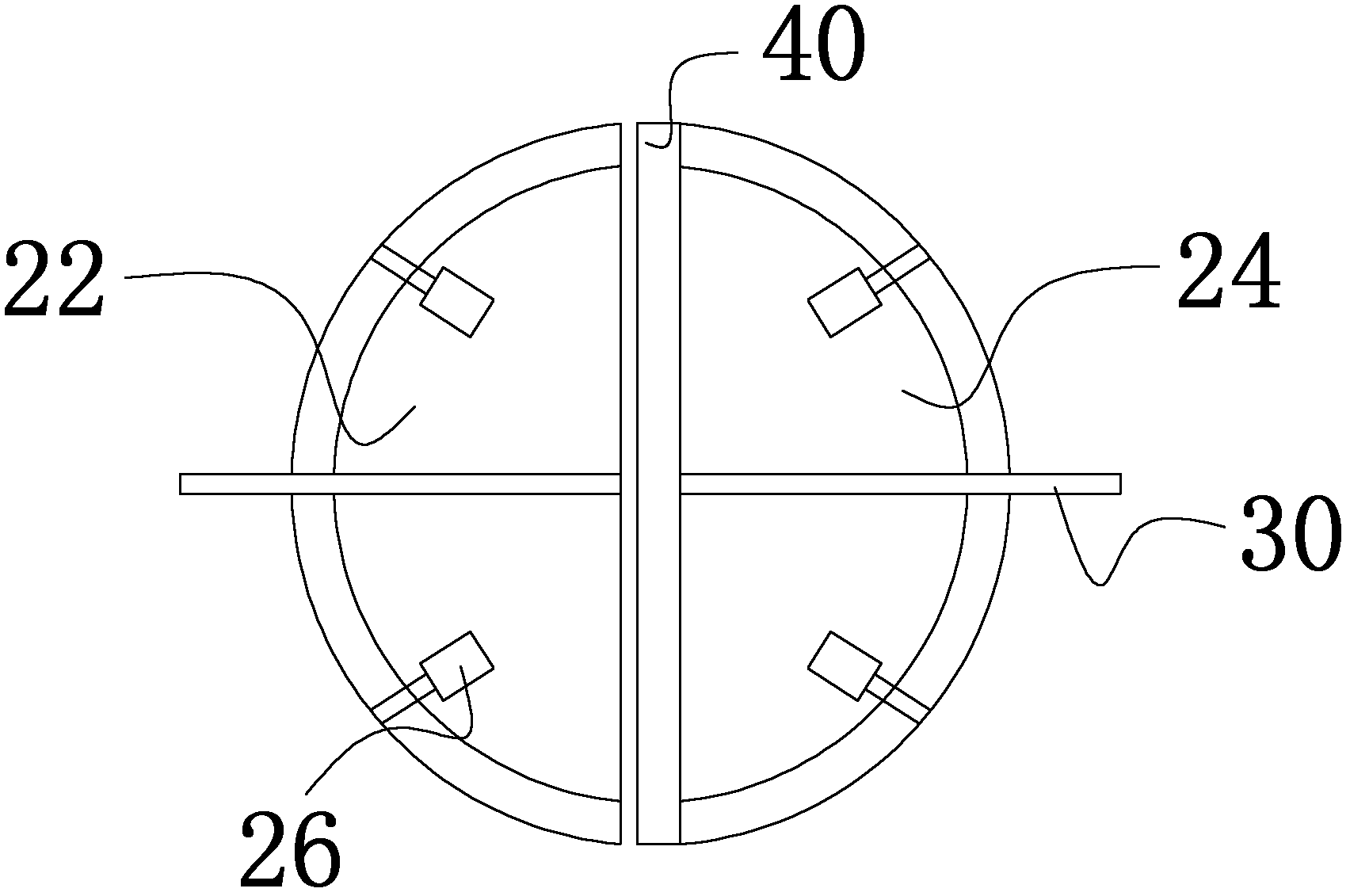

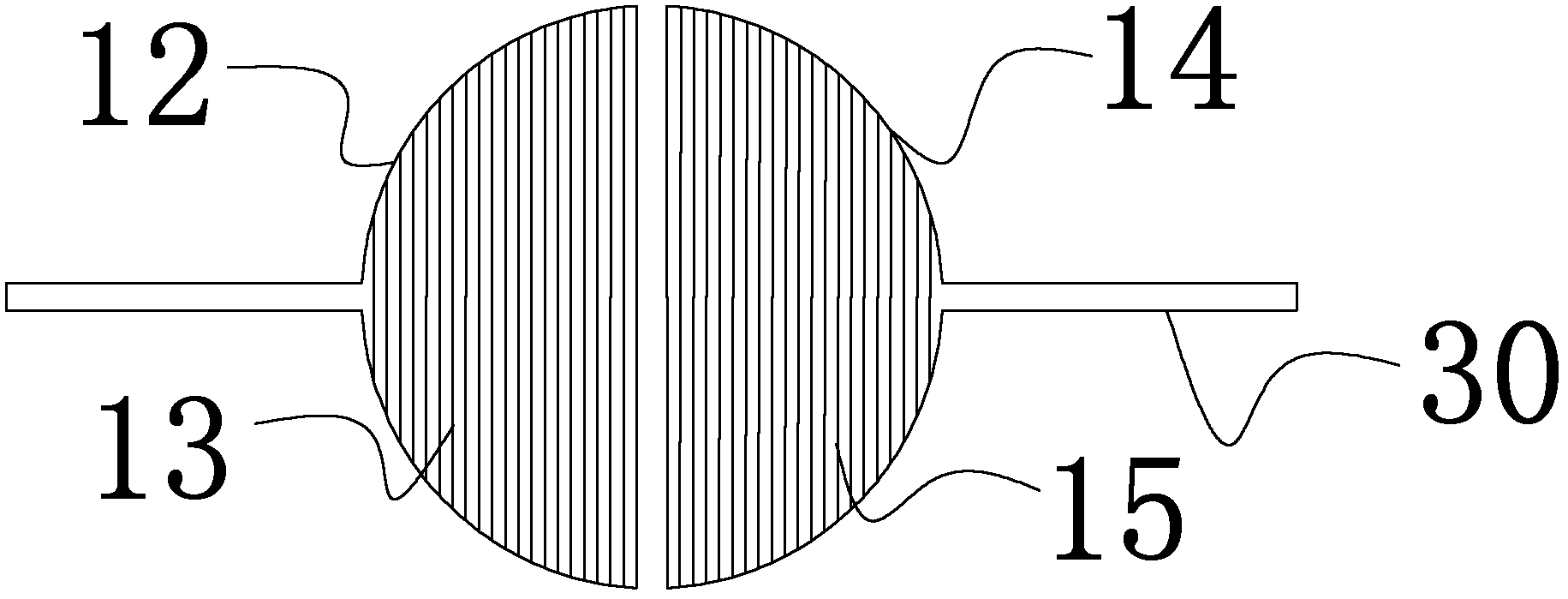

[0026] as attached figure 1 As shown, a kind of spherical motor of the present invention includes a stator 10 fixed on a fixed shaft 30, a rotor 20 that can rotate circumferentially around the fixed shaft 30, and the stator 10 is provided with a winding group ( figure 1 not shown in), the rotor 20 is provided with a plurality of permanent magnets 26, the rotor 20 is hollow spherical, the permanent magnets 26 are fixed on the hollow inner shell of the rotor 20, and the fixed shaft 30 passes through through the center of the sphere of the rotor 20; the stator 10 is a solid sphere with a winding group inside, and the fixed shaft 30 passes through the center of the sphere of the stator 10; the radius of the stator 10 is smaller than that of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com