Three degree of freedom spherical motor with multiple physical field mixing driving

A hybrid drive and multi-physics technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of affecting the output power of the motor, strong noise, and limiting the output of the motor Torque and other issues, to reduce the number of stator windings, simplify the control system design, improve the effect of output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

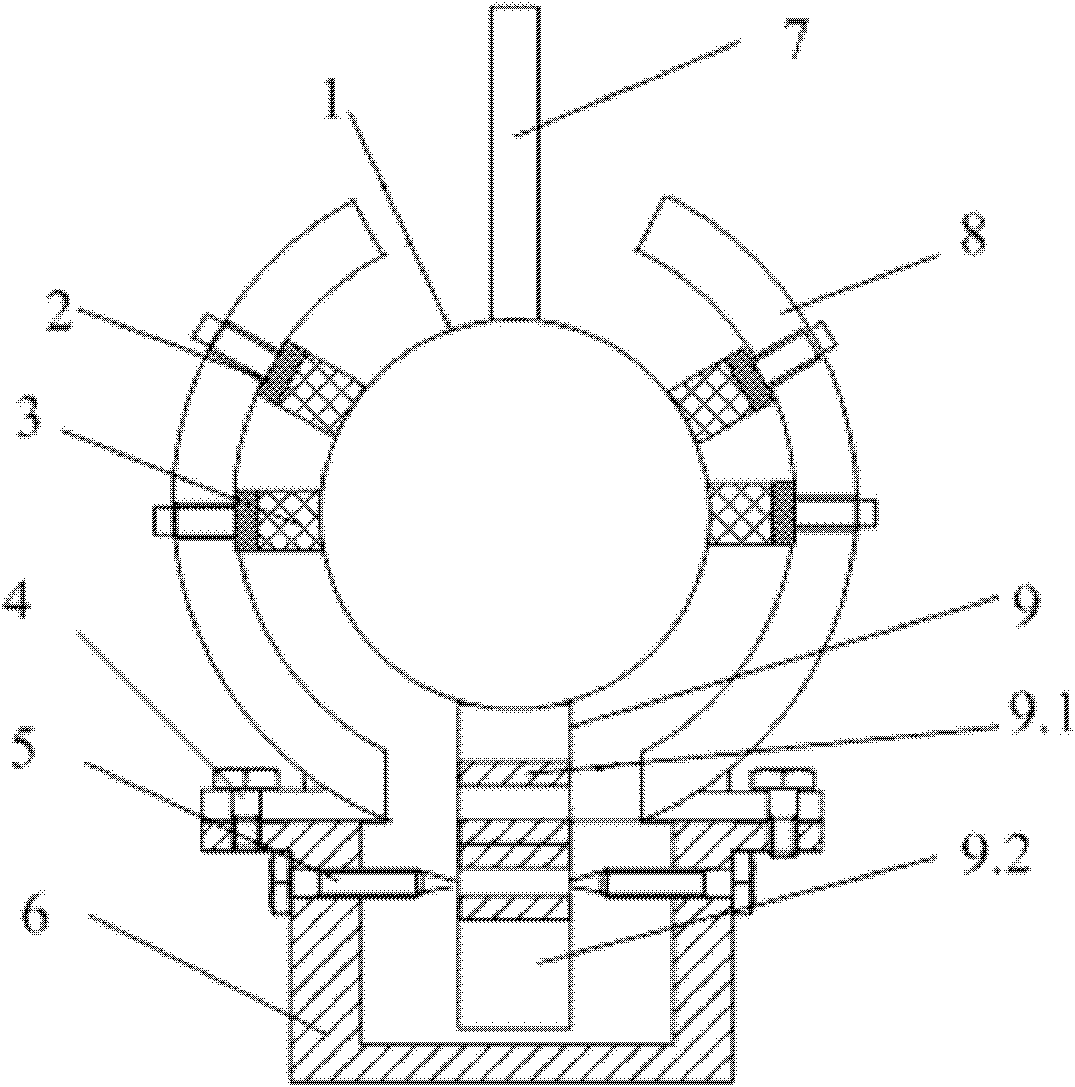

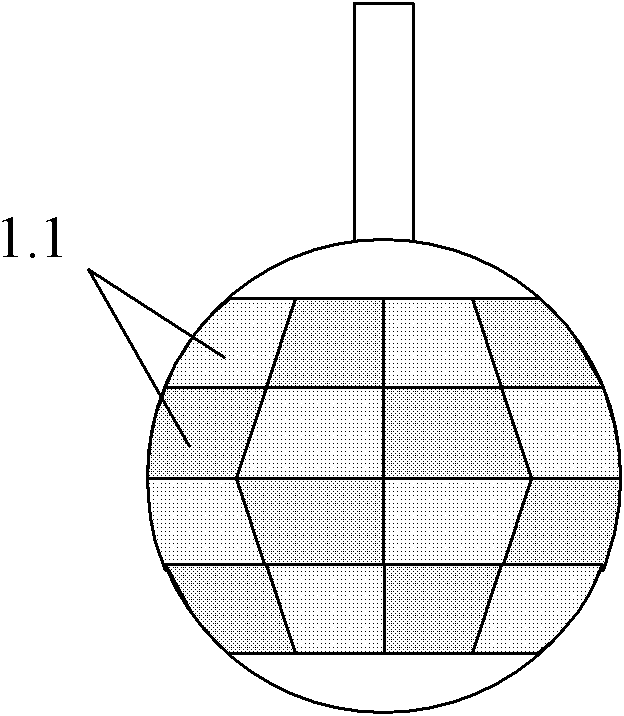

[0024] The multi-physics field hybrid drive three-degree-of-freedom spherical motor of the present invention includes three parts: a support part, a stator and a spherical rotor, wherein the support part includes a stator shell 8, a spring 2, a base 6 and a support bolt 5, and the stator includes a stator winding 3, an ultrasonic The vibrator 9 and the output shaft 7 are fixed on the spherical rotor 1. The basic structure of the motor is as figure 1 shown.

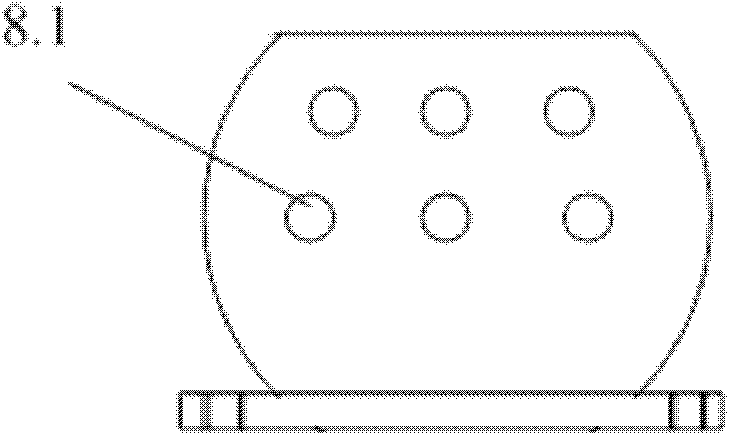

[0025] The stator case 8 is a spherical structure, fixed on the base 6 by bolts 4, a round hole is opened at the top of the stator case, and the output shaft 7 protrudes from it to connect the output torque and force. The size of the round hole is determined by the pitch angle of the motor. The upper hemisphere of the stator shell is evenly distributed along the equator with multi-layer winding installation holes 8.1. The installation holes 8.1 are through holes. The number of layers and density of the installation holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com