Permanent magnet bearing-free auto-suspension three-degree-of-freedom spherical motor and control method thereof

A spherical motor, bearingless technology, applied in the direction of electrical components, magnetic attraction or thrust holding device, etc., can solve the problems of reducing friction, strong pressure, damage to the rotor surface, etc., to simplify design, improve motion characteristics, The effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

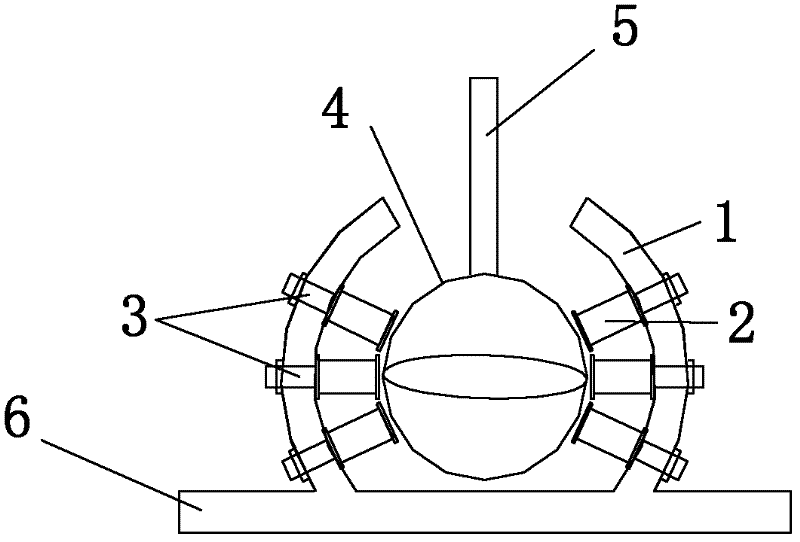

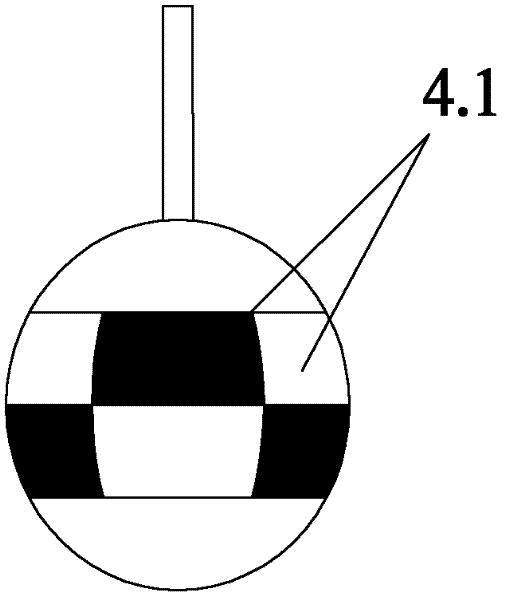

[0025] The permanent magnet bearingless self-suspending three-degree-of-freedom spherical motor includes a supporting part, a stator and a spherical rotor sensor. The supporting part includes a stator wall 1, a base 6, a stator including a hollow coil 2, a coil bolt (3), and a spherical rotor 4. 上fix the output shaft 5. The basic structure of the motor is as figure 1 Shown. Permanent magnet poles 41 are pasted on the surface of the rotor. The poles are divided into upper and lower layers along the equator. Each layer has 6 poles. Each layer has alternate N and S poles, and the upper and lower layers alternate N and S poles. Such as figure 2 Shown.

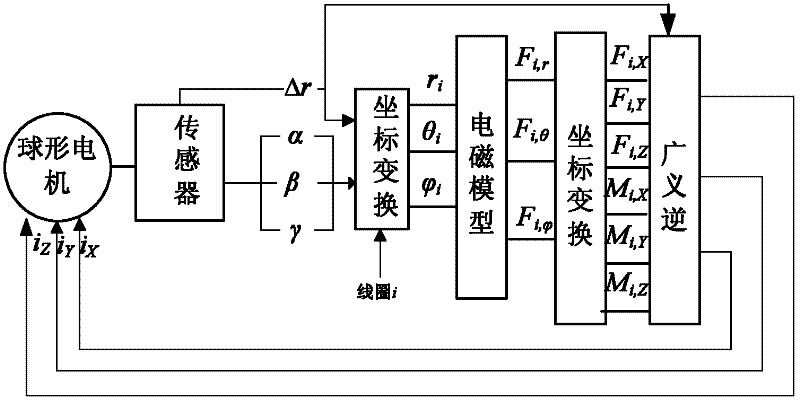

[0026] When the stator winding is energized, the electromagnetic force received by the winding will contain a radial component and a tangential component. The radial component of the electromagnetic force does not produce electromagnetic torque, but it can cause the rotor to shift in position. Before the motor runs, the rotor is sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com