Double clutch

A dual-clutch, clutch technology, applied in clutches, friction clutches, fluid-driven clutches, etc., can solve problems such as motion instability, dual-clutch tilt, etc., and achieve the effect of improving motion characteristics and high motion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

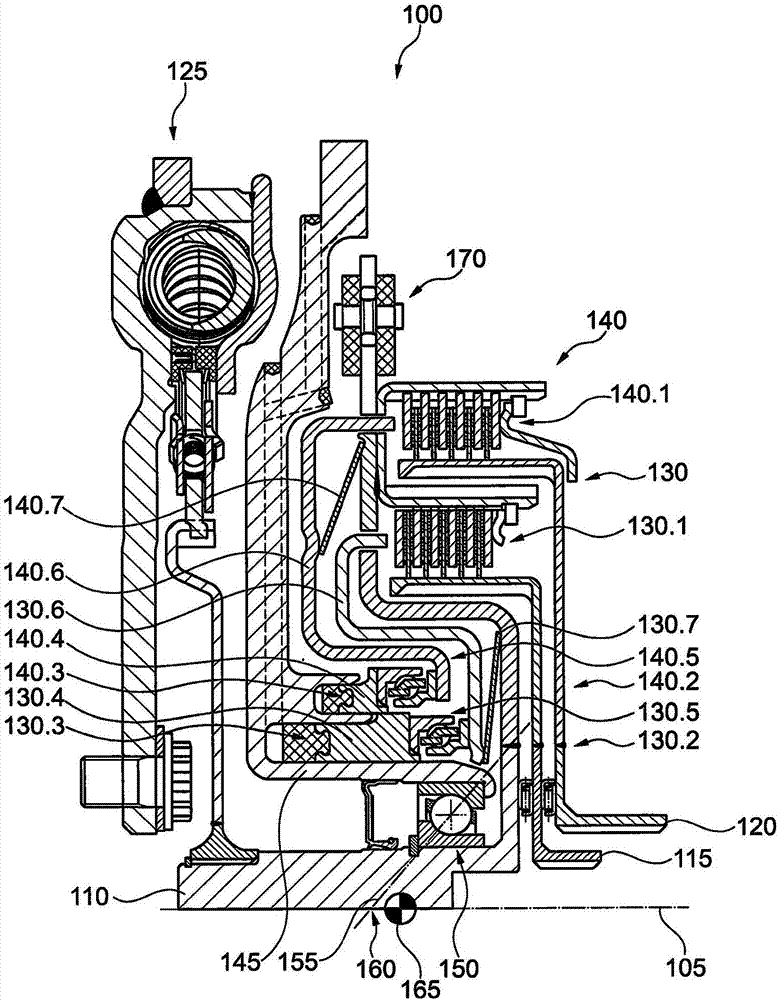

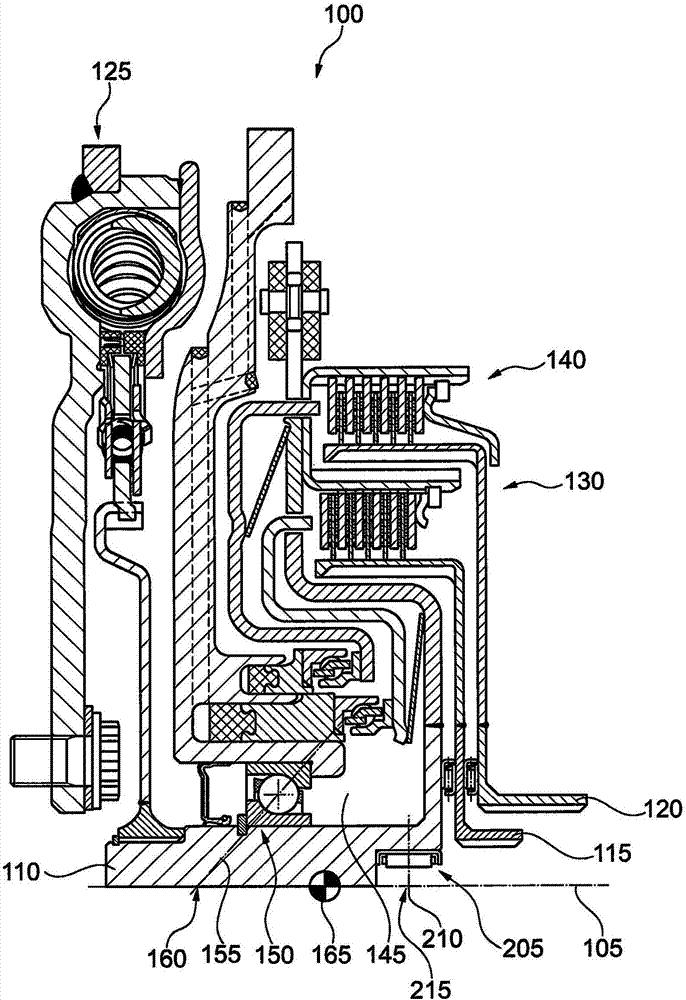

[0019] figure 1 A dual clutch 100 is shown especially for use on a drive train of a vehicle. The input side 110 , the first output side 115 and the second output side 120 are arranged rotatably about the axis of rotation 105 . In the illustrated embodiment, an optional damper 125 is connected to the input side 110 , which can be designed, for example, as a dual-mass flywheel.

[0020] Dual clutch 100 includes a first clutch 130 and a second clutch 140 , which are arranged radially offset in the present embodiment. The two clutches 130, 140 are substantially identical in construction. Among them, representatively, only the first clutch 130 will be discussed in detail below. In this case, the reference numerals of the elements of the clutches 130 , 140 are preceded by the reference numerals of the corresponding clutches 130 , 140 .

[0021] The first clutch 130 includes a first disk set 130 . 1 for torque transmission between the input side 110 and the first output side 115 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com