High-speed precision press

A press and precision technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve problems such as low work efficiency, low manufacturing precision, vibration, etc., to achieve the effect of eliminating low work efficiency and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

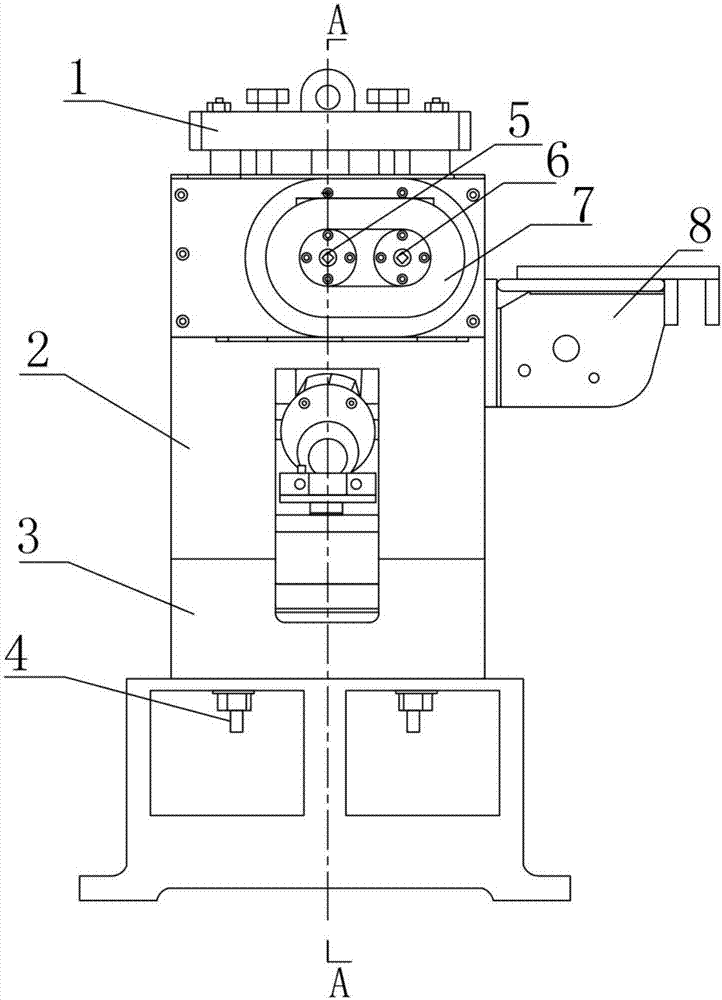

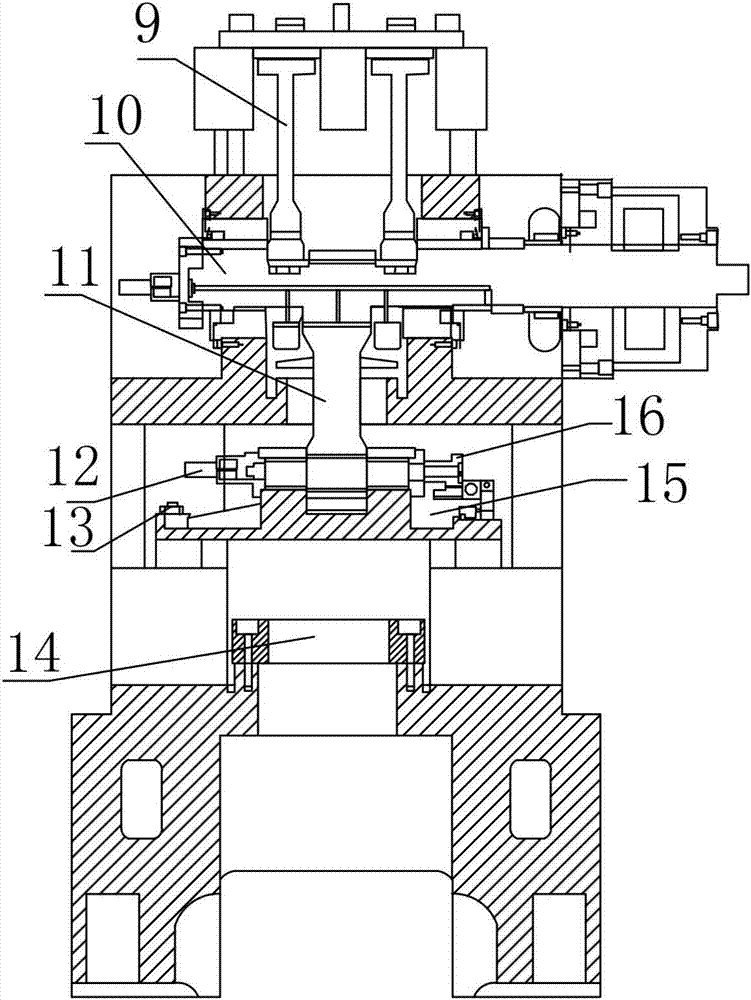

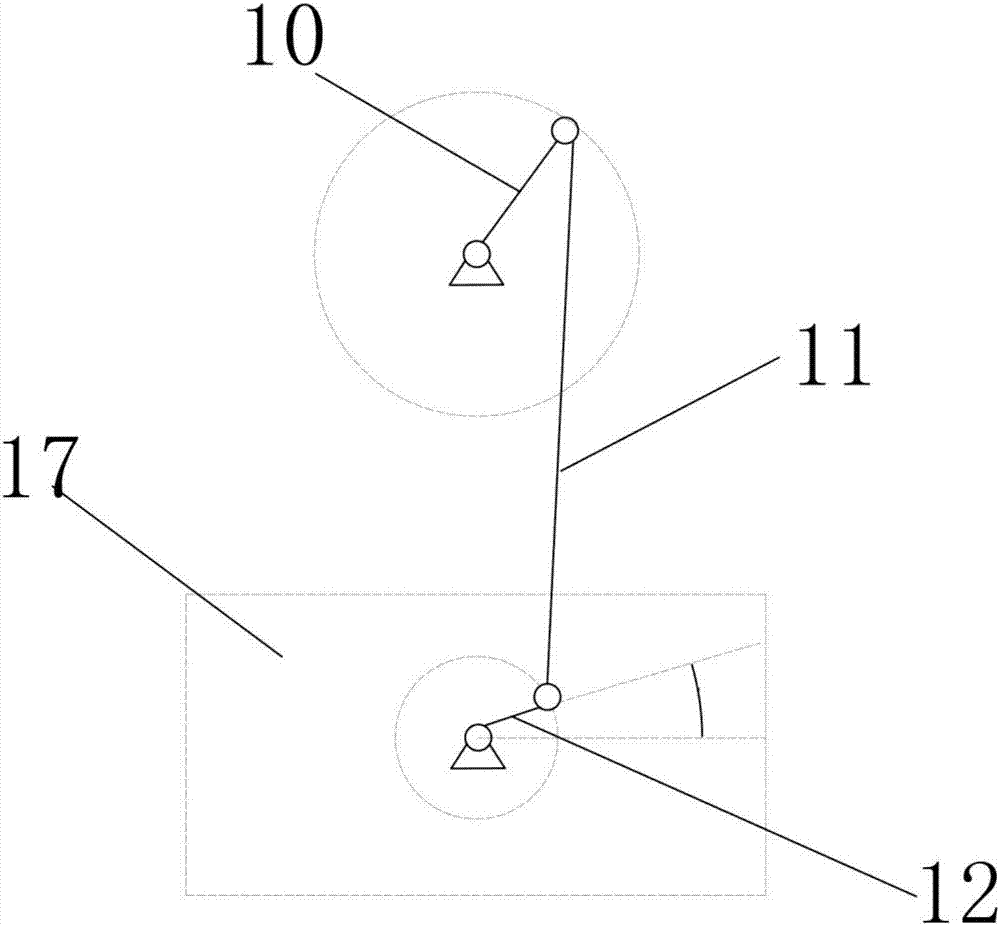

[0027] A high-speed precision press, including a working mechanism, a transmission system, a servo motor, and a fuselage. The fuselage includes a balance weight 1, a column 2, a base 3, a screw 4, a motor bracket 8, and a workbench 14. The column 2 Connect together with base 3 by screw rod 4; Described transmission system is arranged on column 2 side, and described column 2 is provided with motor support 8, and described transmission system is connected with servomotor and crank 10; Described working mechanism comprises crank 10 , connecting rod 11, slide block 17, described crank 10 is connected with slide block 17 by connecting rod 11; Described transmission system comprises noncircular gear transmission and belt transmission, and described noncircular gear transmission comprises noncircular driving gear 6, noncircular The circular driven gear 5, the non-circular driving gear 6 and the non-circular driven gear 5 are arranged in the non-circular gear box 7, and the non-circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com