Microminiature wheeling-walking combined wall climbing robot mechanism

A wall-climbing robot and composite technology, which is applied in the directions of motor vehicles, transportation and packaging, can solve the problems of poor motion performance, complex structure and high power consumption, and achieve the effects of good motion characteristics, flexible motion and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

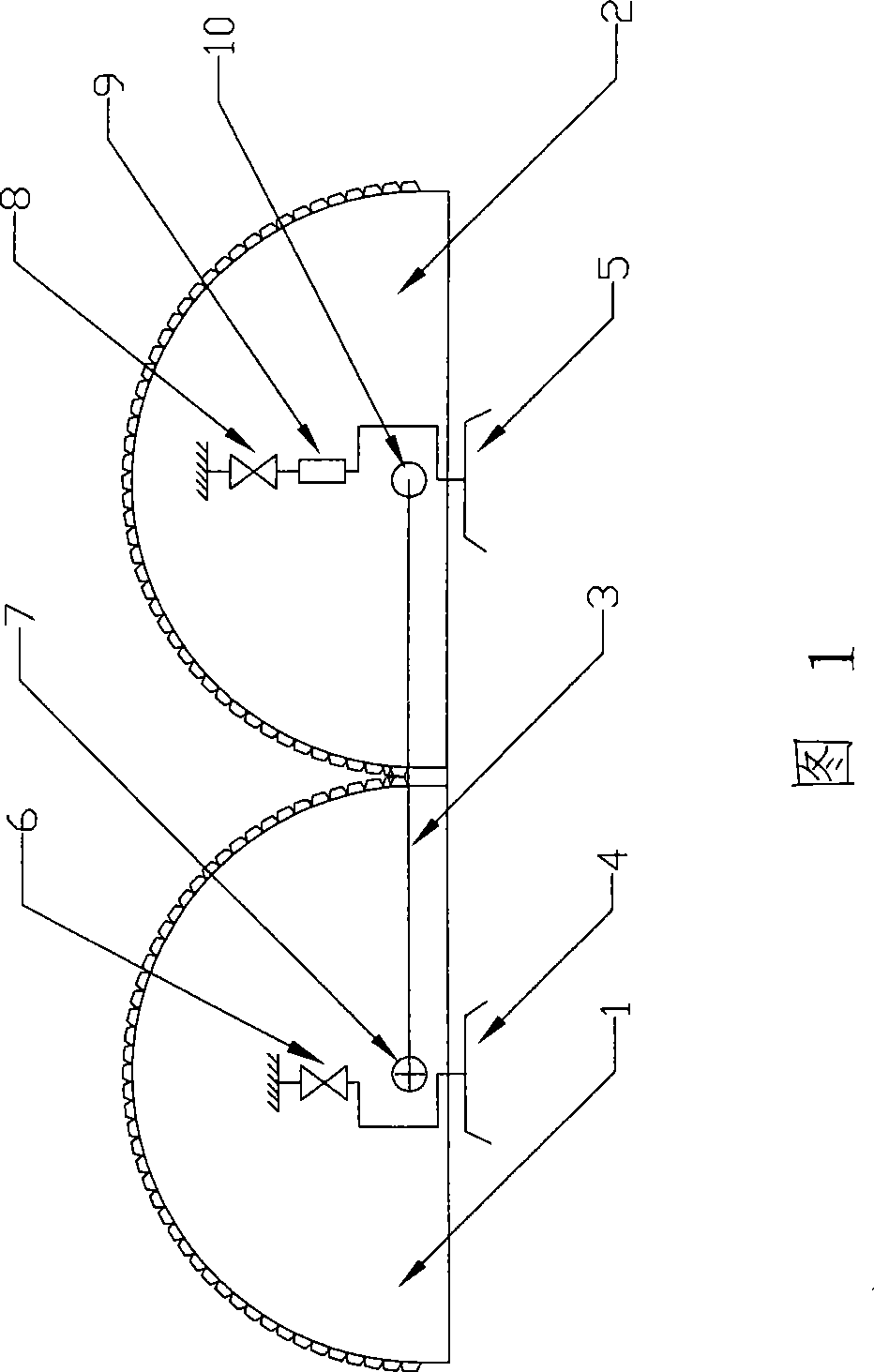

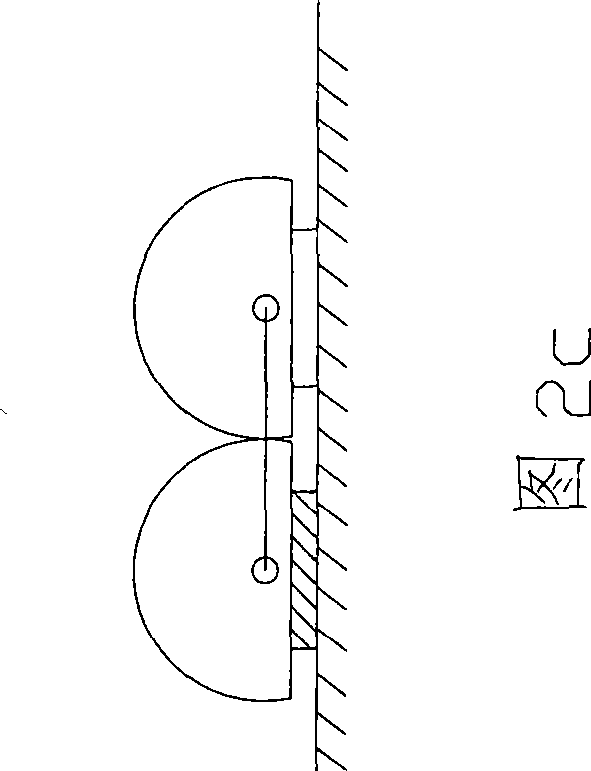

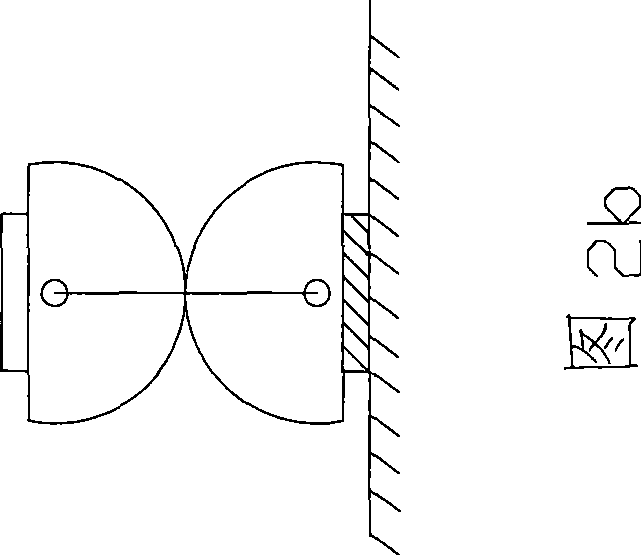

[0036] As shown in Figure 1, the mechanical structure of the present invention consists of a first body 1, a second body 2, a connecting rod 3, a first suction cup foot 4 connected to a vacuum pump, and a second suction cup foot 5, wherein: the first body 1 and the second suction cup foot The two bodies 2 are connected by the connecting rod 3 through the second revolving joint 7 and the fourth revolving joint 10, the first sucker foot 4 is connected with the first body 1 through the first revolving joint 6 (vertical setting), and the second sucker foot 5 is connected by mutual The third rotary joint 8 (vertical setting) and the first mobile joint 9 (vertical setting) in series are connected with the second body 2; the first rotary joint 6, the second rotary joint 7, the third rotary joint 8, the first mobile joint 9 are respectively connected with the motor drive.

[0037] The mechanism of the present invention has four degrees of freedom. The first rotary joint 6, the second ...

Embodiment 2

[0045]As shown in FIG. 6 , the difference between the mechanism of the present invention and Embodiment 1 is that the fourth rotating joint 11 (set horizontally) replaces the moving joint 9 . Compared with Example 1, Example 2 realizes the spanning of the crossing wall surface of the inventive mechanism by means of the fourth rotary joint 11 .

Embodiment 3

[0047] As shown in Figure 7, the difference between the mechanism of the present invention and Embodiment 1 is that the fourth rotary joint 10 on the second sucker foot 5 is removed, and a second moving joint 12 is added on the connecting rod (horizontally arranged, with the connecting rod same direction) to realize the relative movement between the two half cylinders.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com