Flywheel energy-accumulating energy-saving-type hydraulic vibration system

A hydraulic vibration and energy-saving technology, which can be used in fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., and can solve problems such as lack of research and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

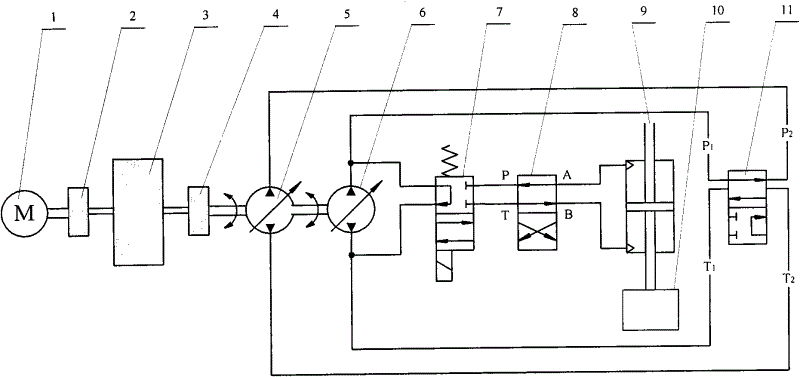

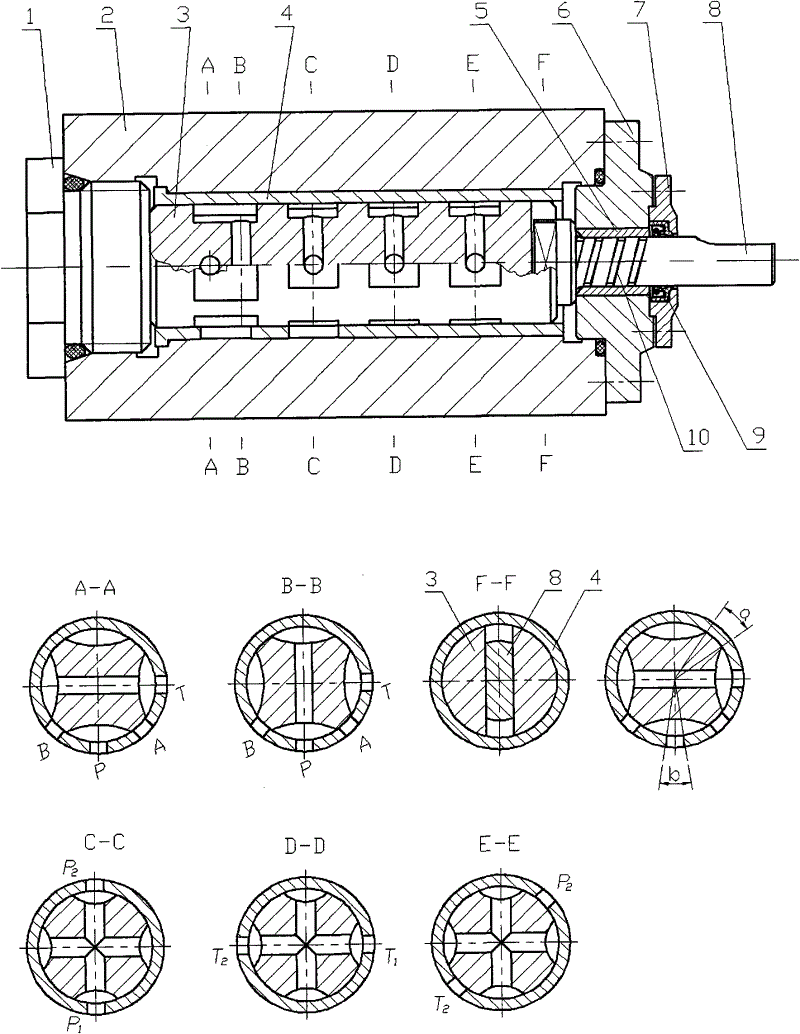

[0018] The invention relates to a flywheel energy storage and energy saving hydraulic vibration system. Includes drives, hydraulic pumps, hydraulic cylinders and hydraulic valves. The driving device includes a motor 1, a hydraulic coupling 2, a flywheel 3 and an elastic coupling 4, and the three are coaxially connected. The hydraulic pump is a duplex pump, including a first hydraulic pump 5 and a second hydraulic pump 6, which are coaxially connected with the elastic coupling 4. The hydraulic valves include a two-position four-way electromagnetic reversing valve 7 , a first two-position four-way reversing valve 8 and a second two-position four-way reversing valve 11 . The solenoid valve 7 and the first reversing valve 8 are connected in series between the second hydraulic pump 6 and the hydraulic cylinder 9 to form a pump-valve-cylinder closed circuit, and the vibration body 10 and the hydraulic cylinder 9 are rigidly connected. Wherein, the T, P oil ports of the electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com