Supercritical/super-supercritical unit heating drain recovery method

An ultra-supercritical unit and hydrophobic recovery technology, applied in feedwater heaters, steam/steam condensers, preheating, etc., can solve the problem of reducing the economy of the regenerative cycle system, large heating and drainage flow, and reducing the overall cycle thermal efficiency of the unit, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

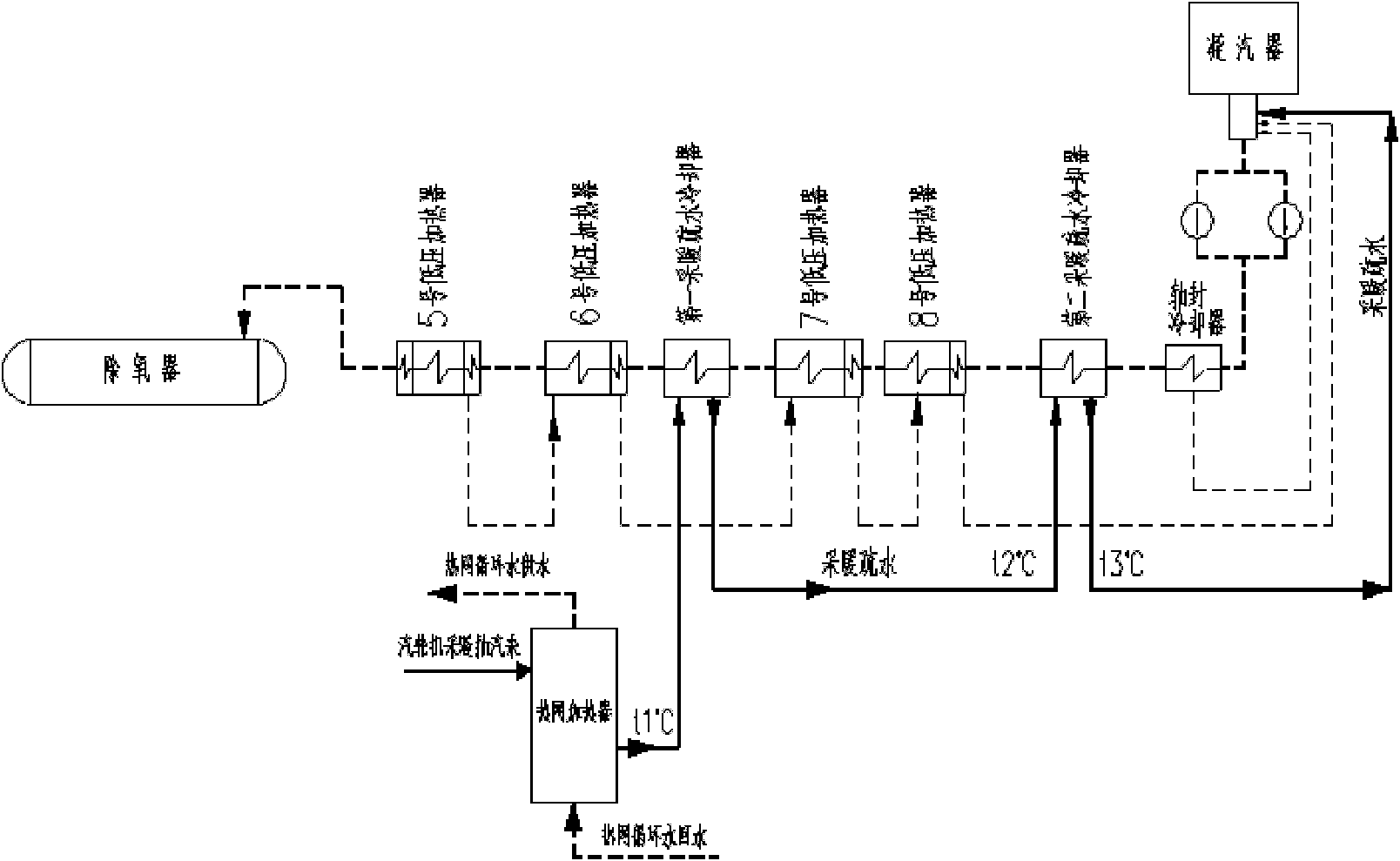

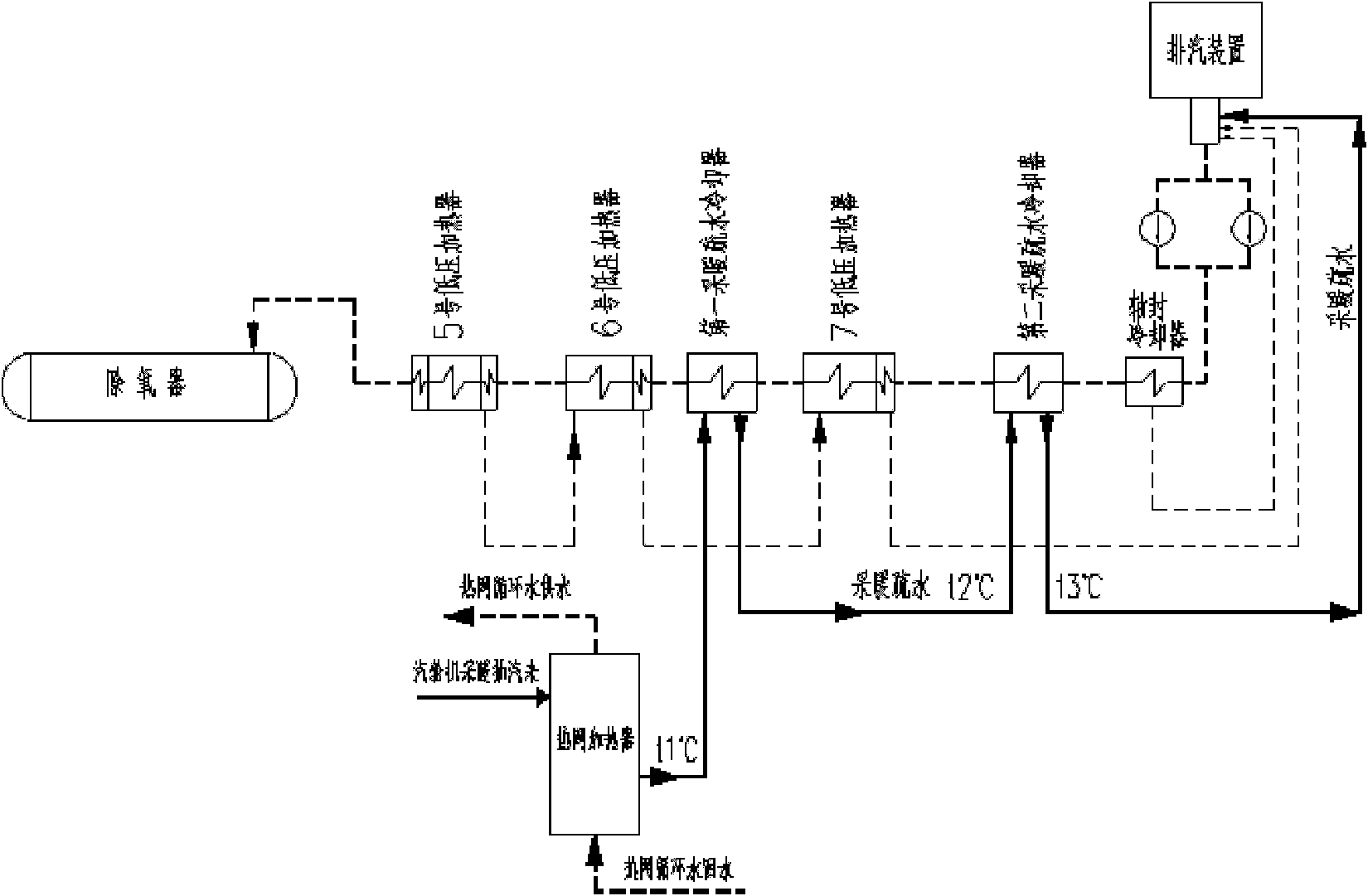

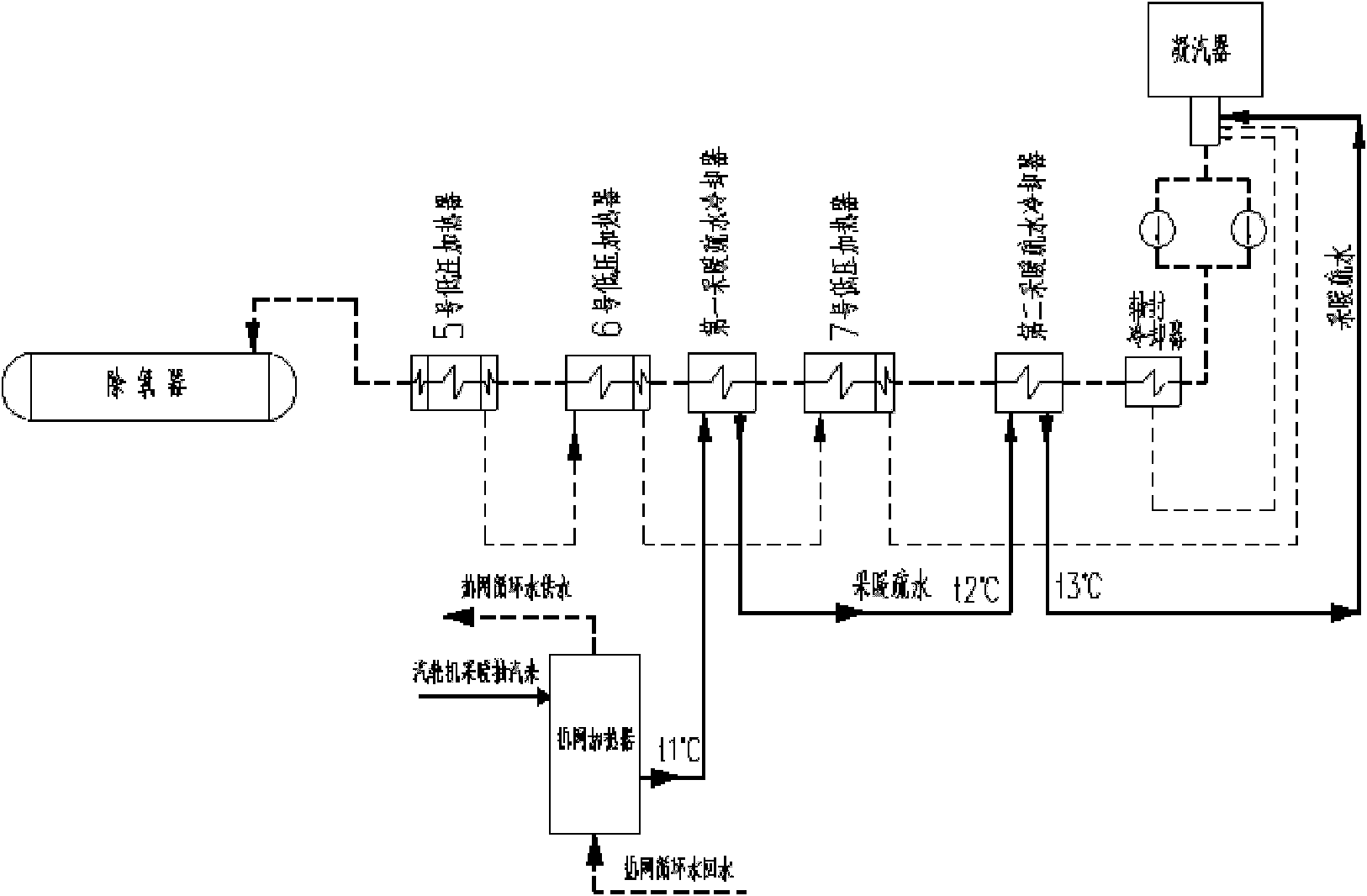

[0028] Such as figure 1 As shown, it is an implementation example of the heating hydrophobic recovery method of the present invention in a supercritical / ultra-supercritical wet-cooling unit.

[0029] Extract the exhaust steam that has worked in the steam turbine as heating steam, and lead it to the heating network heater; heat exchange in the heating network heater increases the temperature of the circulating water in the heating network, and at the same time, the heating steam transforms after releasing heat For heating and drainage; the specific recycling methods and steps for heating and drainage are as follows:

[0030] (a) First lead the heating drainage from the outlet of the heating network heater to the first heating drainage cooler installed on the condensate pipeline of the main engine between No. 6 low-pressure heater and No. 7 low-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com