A two-for-one twister with automatic brake for broken yarn

A technology of automatic braking and double twisting machine, applied in the textile field, can solve the problems of high yarn wear, high energy consumption of twisting device, and high product hairiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

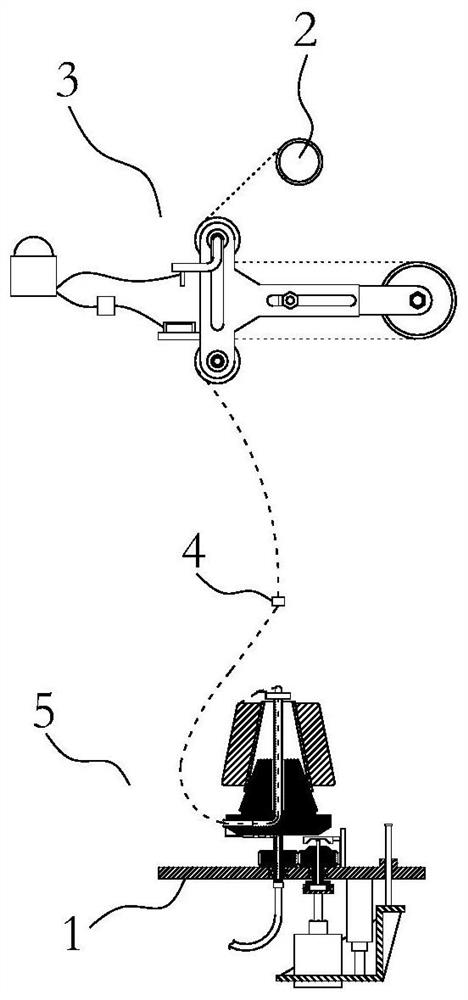

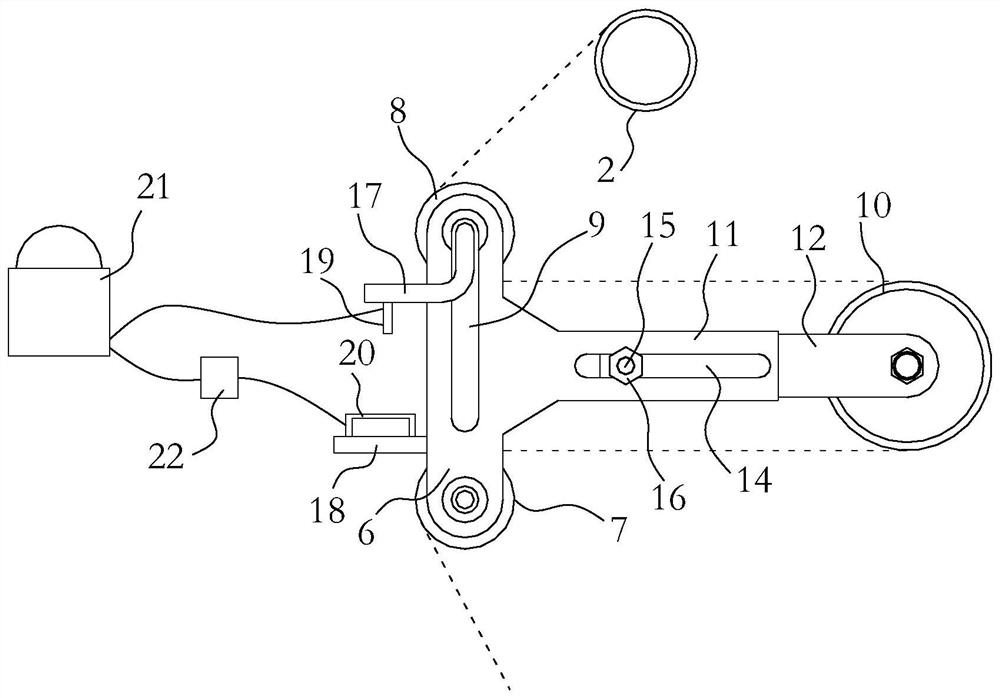

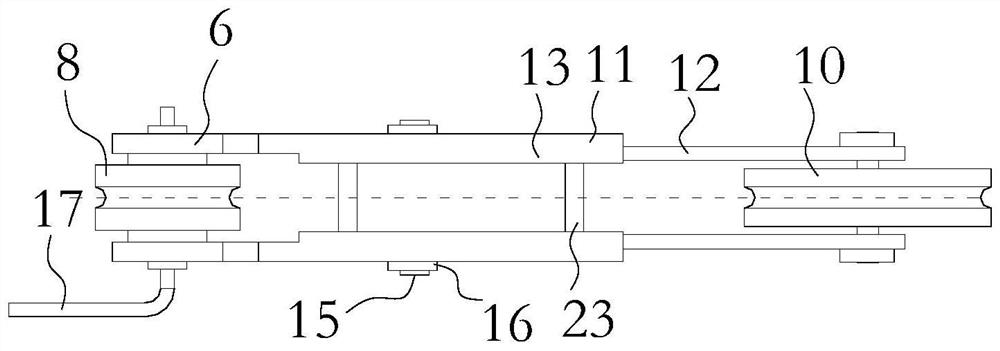

[0031] Such as Figure 1-9 As shown, a two-for-one twister with automatic braking of broken wires is similar to a traditional two-for-one twister. The present invention also includes a winding device 2, a wire breakage detection device 3, Yarn collector 4 and twisting device 5. The yarn is wound on the winding device 2 after passing through the twisting device 5, the yarn collector 4, and the yarn break detection device 3 in sequence. The winding device 2 is used for winding and collecting the twisted yarn, the broken thread detection device 3 is used for detecting whether the yarn on the two-for-one twister is broken, and the yarn collector 4 is used for performing a check on the yarn. Guiding and converging, the twisting device 5 is used to twist the yarn to improve the toughness, appearance, strength and other qualities of the yarn. Of course, in addition to the above-mentioned devices, the present invention can also add other two-for-one twisting related equipment such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com