Casting drawing device and drawing method thereof

A technology for casting models and molds, which is applied in the field of casting mold lifters and mold lifters, can solve the problems of time-consuming screw in and out, broken models, and damaged models, so as to reduce production costs, improve production efficiency, Eliminate the effect of mold damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

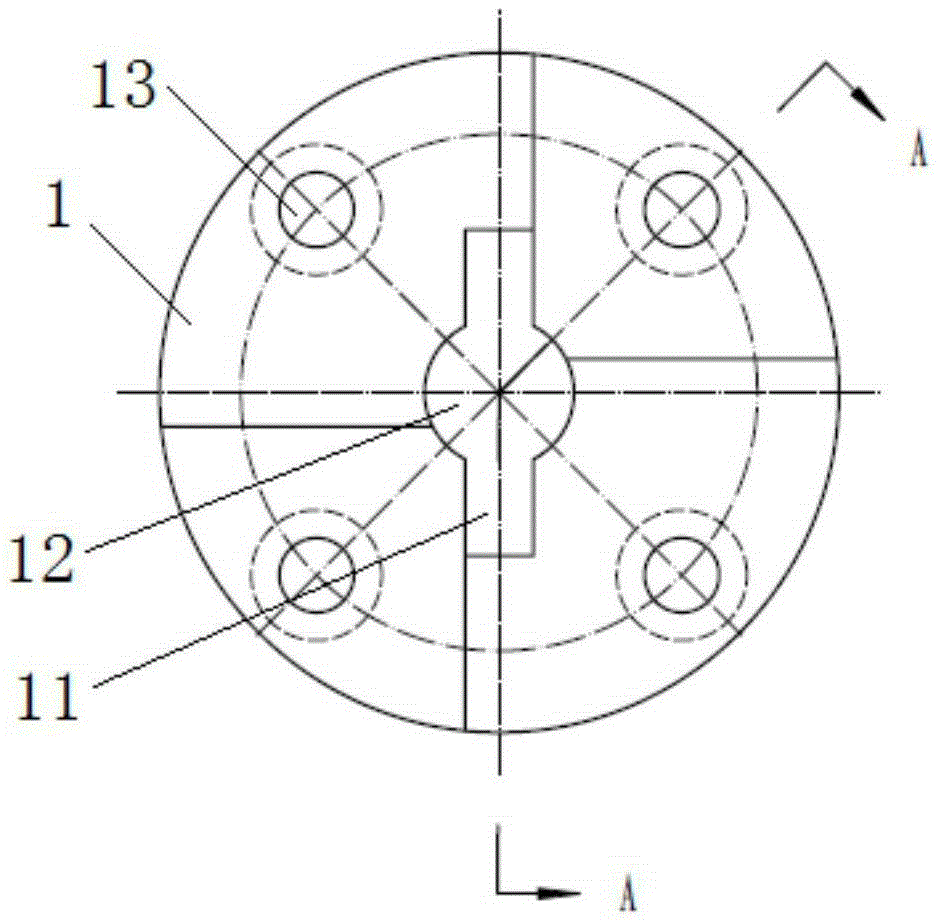

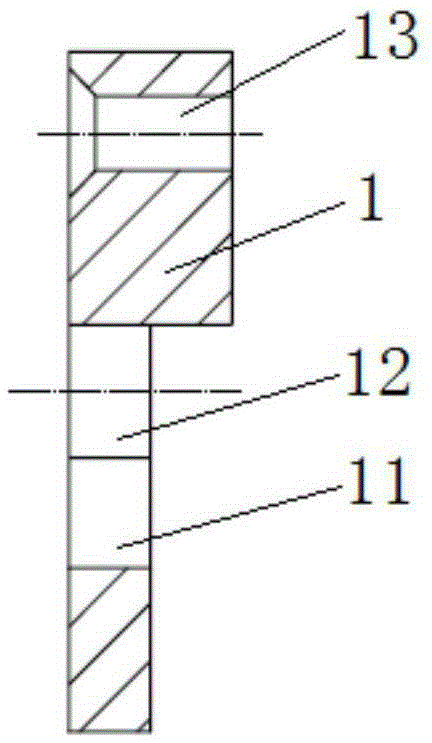

[0030] refer to Figure 1-3 , The casting ejector described in this embodiment includes a fixed plate 1 and an ejector rod.

[0031] The fixed plate 1 is made of medium carbon steel, and has undergone quenching and tempering heat treatment and surface oxidation treatment. The fixed plate 1 has a circular shape as a whole, and is equally divided into four fan-shaped areas as a whole, wherein the thickness of two opposite fan-shaped areas is greater than the thickness of the other two opposite fan-shaped areas. A counterbore 13 is provided near the edge of each fan-shaped area of the fixed plate 1; a through hole 12 is provided in the center of the fixed plate 1, and square grooves 11 are respectively provided on the upper and lower sides of the through hole 12. The outer diameter of the fixed plate is 50mm, 60mm, 65mm or 70mm.

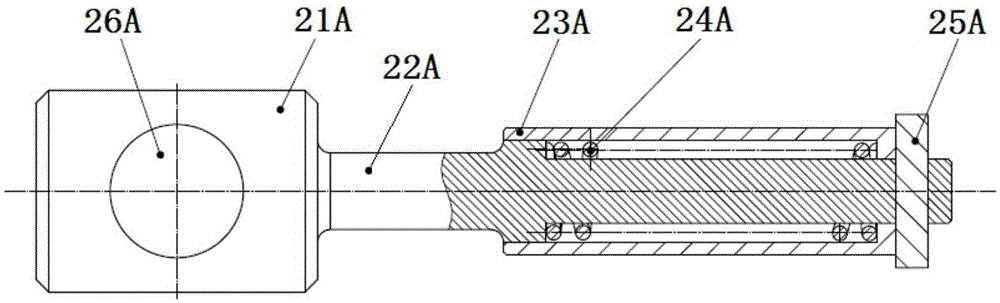

[0032] The ejector lever is a lifting type ejector lever, which includes a rod body 22A, a handle 21A, a sleeve 23A, a spring 24A and a square pin ...

Embodiment 2

[0034] refer to figure 1 , 2 , 4. The casting ejector described in this embodiment includes a fixed plate 1 and an ejector rod.

[0035] The fixed plate 1 is made of medium carbon steel, and has undergone quenching and tempering heat treatment and surface oxidation treatment. The fixed plate 1 has a circular shape as a whole, and is equally divided into four fan-shaped areas as a whole, wherein the thickness of two opposite fan-shaped areas is greater than the thickness of the other two opposite fan-shaped areas. A counterbore 13 is provided near the edge of each fan-shaped area of the fixed plate 1; a through hole 12 is provided in the center of the fixed plate 1, and square grooves 11 are respectively provided on the upper and lower sides of the through hole 12. The outer diameter of the fixed plate is 50mm, 60mm, 65mm or 70mm.

[0036] The ejector lever is a hand-held ejector lever, comprising a rod body 22B, a handle 21B, a sleeve 23B, a spring 24B and a square pin 25...

Embodiment 3

[0058] Ejecting method embodiment 3 (4 fixed plates are installed):

[0059] The present embodiment is to apply the casting mold lifter to the K30 / 150 type air compressor fuselage model. The weight of this model is 65kg. Install the four fixed plates.

[0060] Select the projection point of the center of gravity of the casting model on the parting surface as the origin, and install the fixed plate 1 at four appropriate symmetrical positions. According to the shape of the casting model, the connecting line between the centers of the four fixed plates should be rectangular (square or rectangular) and the fixed plate Install it at an appropriate position symmetrical to the center of gravity of the model, and ensure that the top surface of the fixed plate or the highest point of the top of the fixed countersunk bolt is 0.5-3mm lower than the parting surface of the model.

[0061] Carry out molding in casting mold with foundry model, molding method and step are known in foundry in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com