Crimping resistance nondestructive measurement tool

A technology for measuring tooling and resistance, applied in measuring devices, measuring electrical variables, workpiece clamping devices, etc., can solve the problems of easy oxidation, time-consuming, inaccurate measurement data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

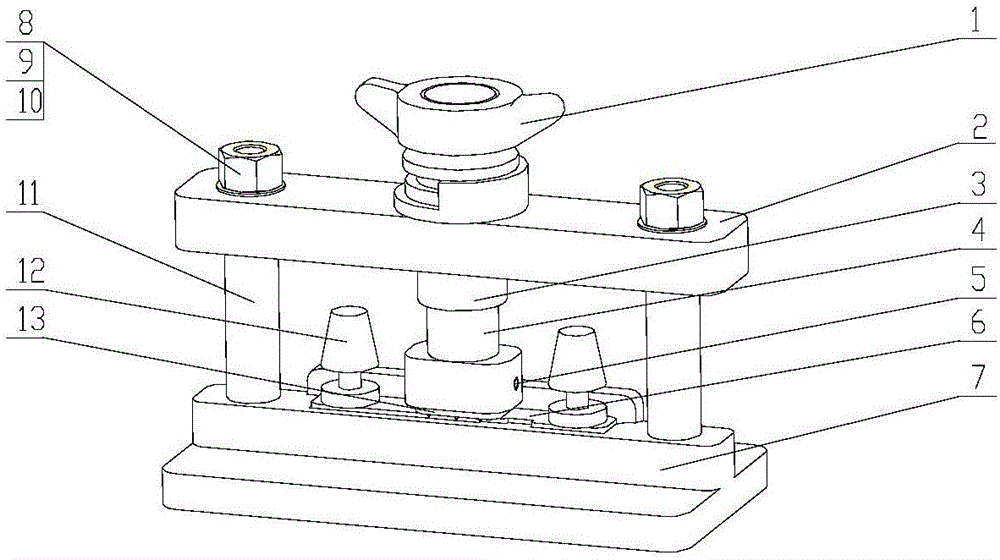

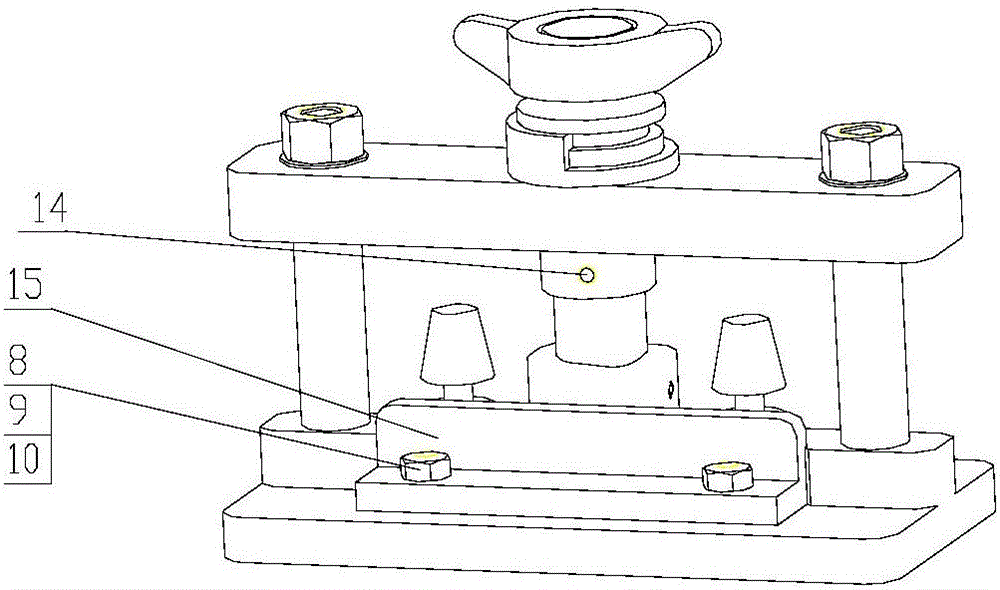

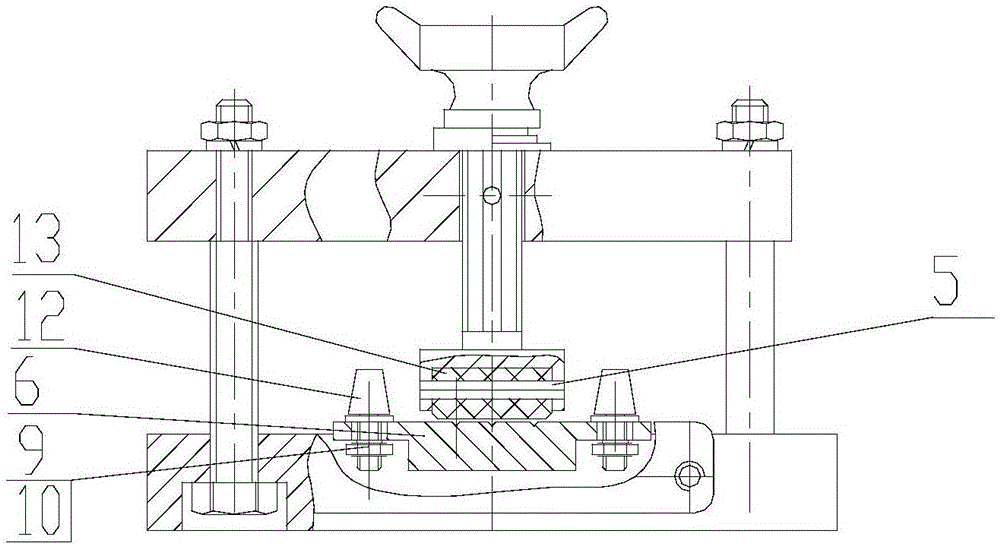

[0016] The invention provides a non-destructive measurement tooling with simple structure, fast clamping, and accurate measurement of wire crimping resistance. The workpiece is clamped by the principle of screw clamping, and various lengths and cross-sectional diameters (0.08 mm) can be realized. 2 ︿3mm 2 ) ) Precise measurement of wire crimping resistance; the specific fixture scheme is as follows:

[0017] The tooling includes 2 clamp bodies and 1 external short circuit piece. The two clamp bodies have the same structure and are placed side by side during work. The elastic pressing blocks on the clamp body tightening components press the two ends of the external short circuit piece to realize the connection. One clamp body is used to clamp the metal crimping end of the wire, and the other clamp body is used to clamp the other core end of the wire. The clamp body includes an upper bracket, a middle tightening component, a support component and a bottom base component. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com