Super-supercritical air cooling steam turbine

An ultra-supercritical and steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as large water consumption, affecting shafting stability, and unusability in water-scarce areas, achieving high thermal efficiency and low heat consumption low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Taking a 600MW ultra-supercritical air-cooled steam turbine as an example, the main steam pressure is 25MPa, the main steam temperature is 600°C, the reheat steam temperature is 600°C, and the design back pressure is 16kPa.

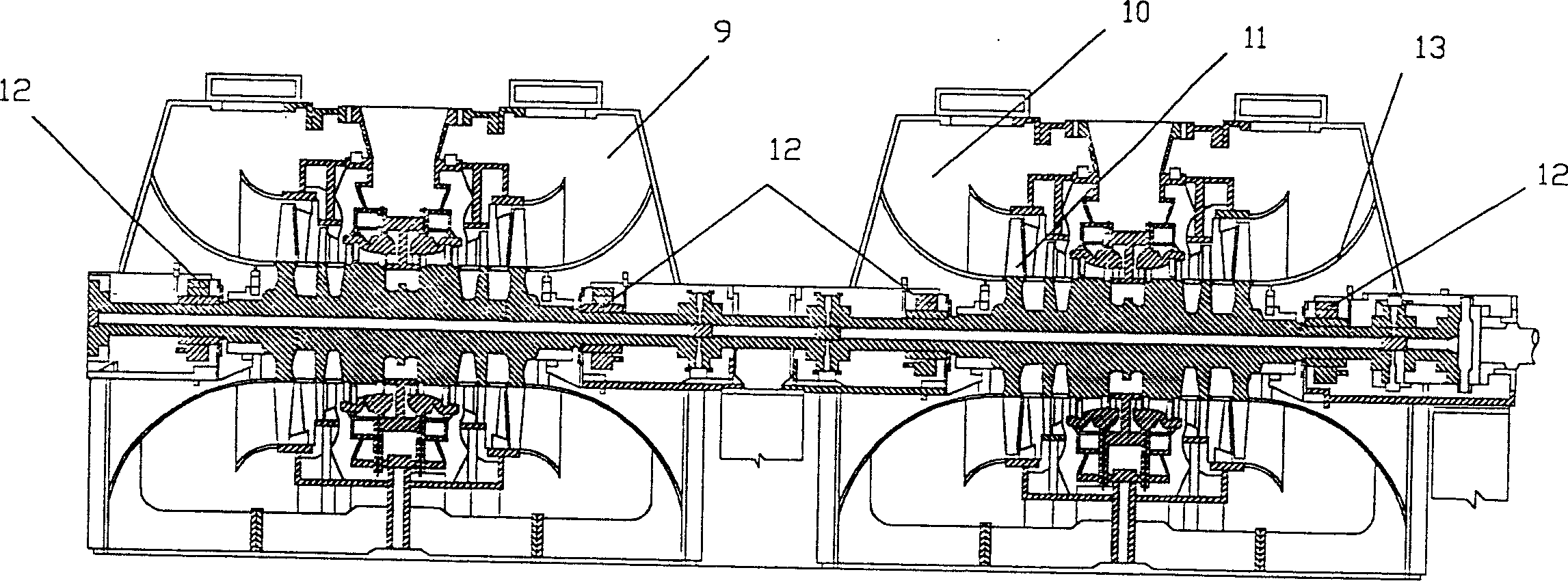

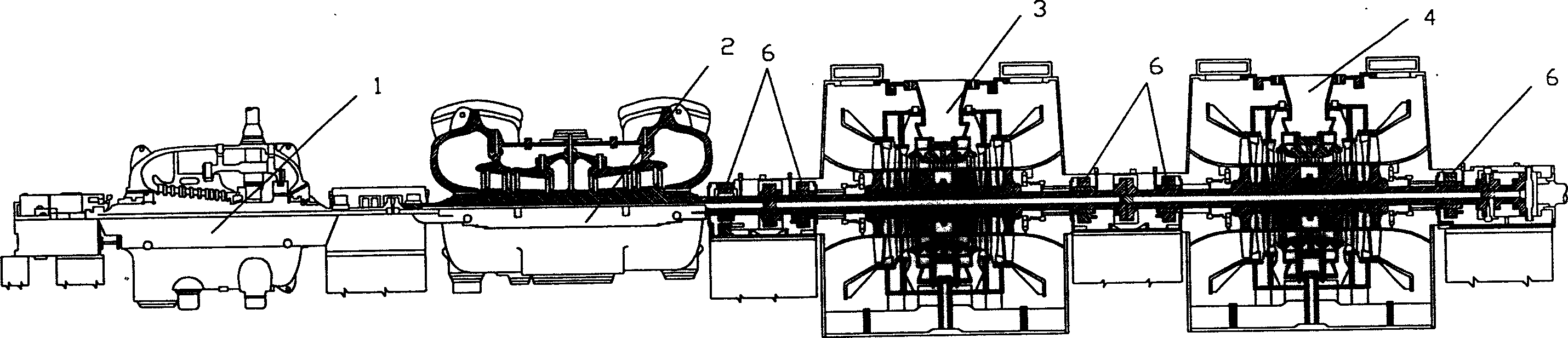

[0029] Such as figure 2 As shown, it is a schematic structural diagram of an ultra-supercritical air-cooled steam turbine, which is composed of a high-pressure cylinder 1 of an ultra-supercritical wet-cooled steam turbine, an intermediate-pressure cylinder 2 of an ultra-supercritical wet-cooled steam turbine, a low-pressure cylinder 3 of an air-cooled steam turbine, and a low-pressure cylinder 4 of an air-cooled steam turbine. Cylinder 4 adopts floor type bearing seat.

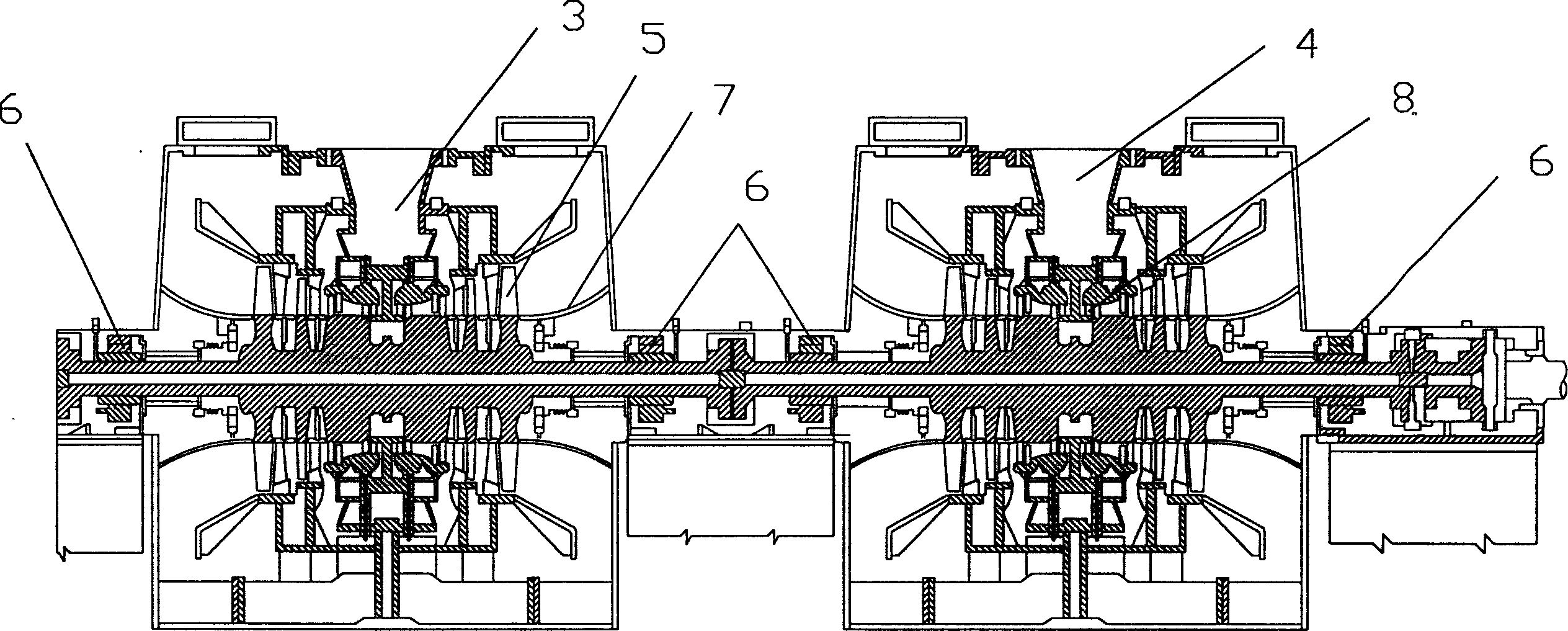

[0030] Such as image 3 As shown, it is a schematic structural diagram of the low-pressure cylinder of an ultra-supercritical air-cooled steam turbine. The height of the first-stage low-pressure moving blade 8 is 201 mm, and the height of the last-stage blade 5 is 664.99 mm; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com