Device special for sanding surfaces of wooden plates

A technology of sanding and wood boards, which is applied in the direction of grinding/polishing safety devices, abrasive belt grinders, grinding/polishing equipment, etc., which can solve the problems of inconvenient internal sanding of devices, shortening the service life of abrasive belts, and easy heating of abrasive belts, etc. problem, achieve the effects of reducing the probability of heating, simple structure, improving quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

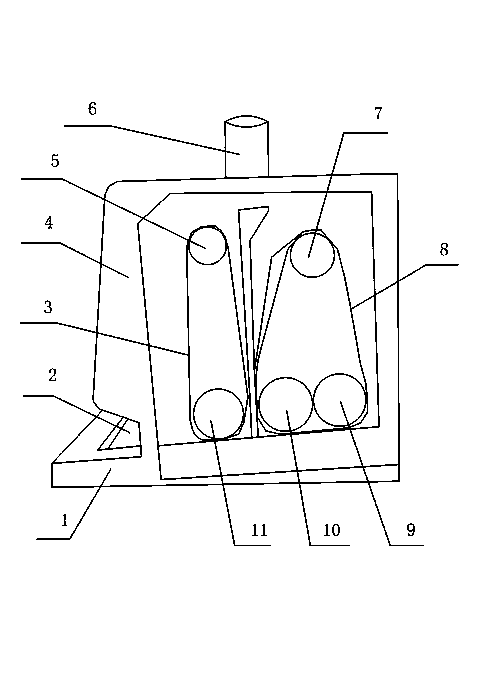

[0012] Such as figure 1 As shown, a device dedicated to sanding the surface of a wooden board includes a base 1 and a casing 4. A pressing device 2 is arranged on the base 1, and a sanding device is arranged above the pressing device 2. The sanding device is arranged in the casing 4; the sanding device includes a runner and an emery cloth, and the runner includes a runner one 5, a runner two 11, a runner three 7, a runner four 9 and a runner five 10, Emery cloth comprises emery cloth one 3 and emery cloth two 8; Runner one 5 is arranged on the top of runner two 11, emery cloth one 3 is arranged on the outer wall of runner one 5 and runner two 11 simultaneously, runner one 5 and runner two 11 is arranged inside the emery cloth-3. Multiple sanding improves sanding efficiency and saves sanding time. Multiple wheels are set to achieve multiple sanding to ensure the surface quality of the material, and the pressing device is placed below to hold the material to ensure that it wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com