Supercritical air cooling steam turbine

A steam turbine, supercritical technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of affecting the stability of the shaft system, large water consumption, unusable in water-deficient areas, etc., achieving low water consumption and high thermal efficiency. , the effect of low heat consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Taking a 600MW supercritical air-cooled steam turbine as an example, the main steam pressure is 24.1MPa, the main steam temperature is 538°C, the reheat steam temperature is 538°C, and the design back pressure is 12.7KPa.

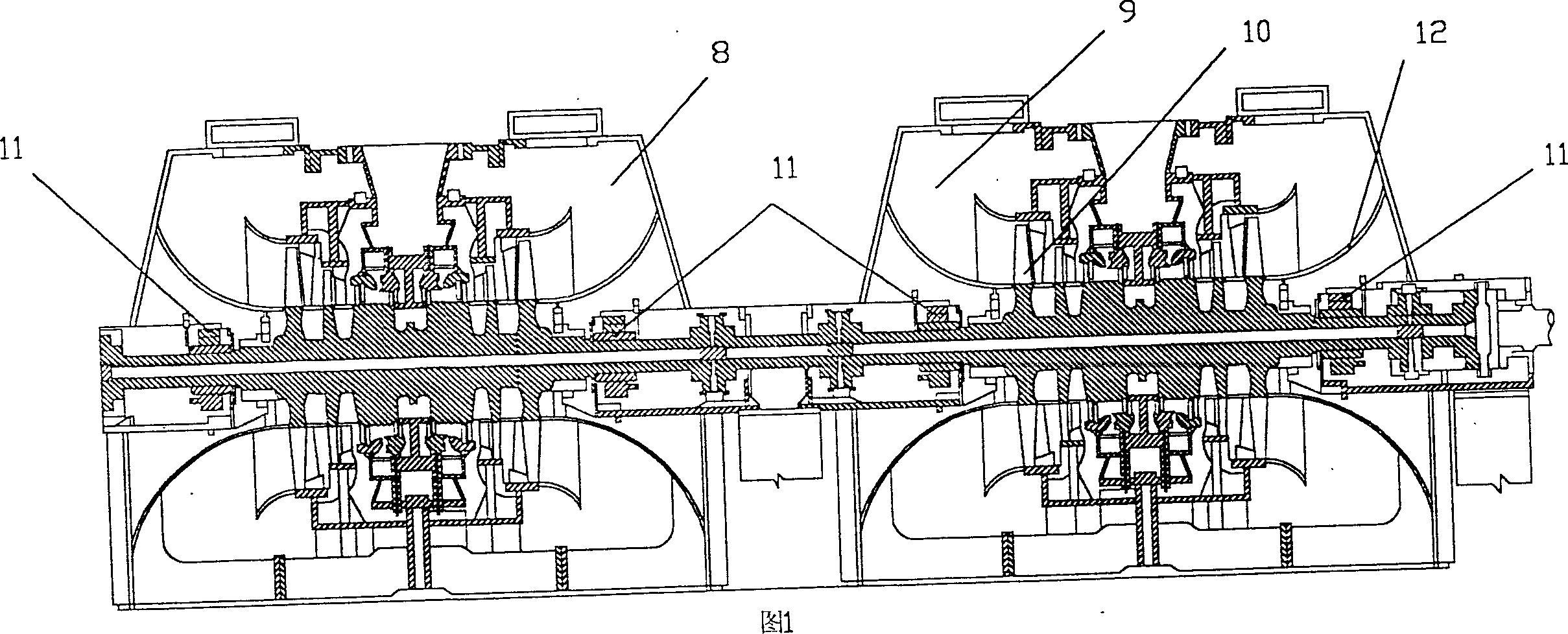

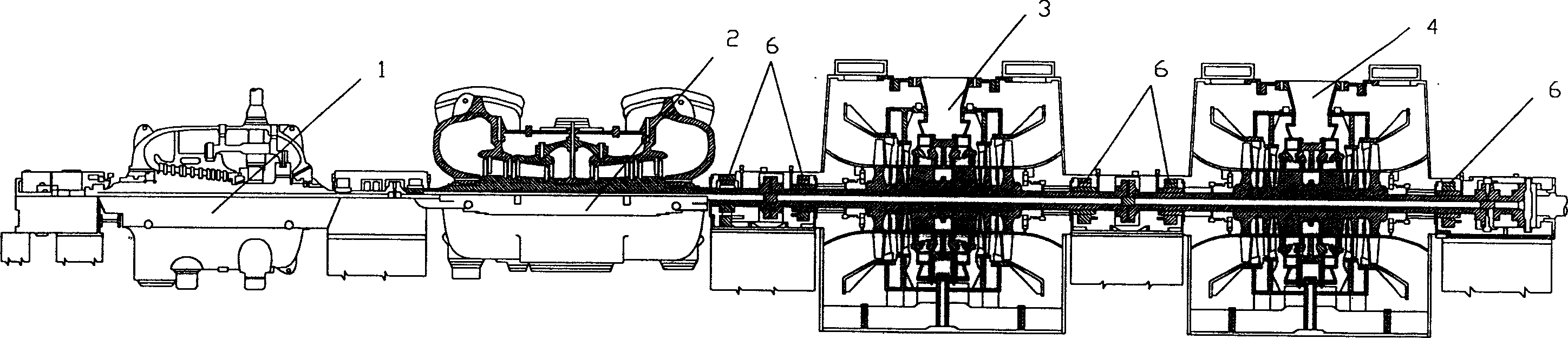

[0027] Such as figure 2 Shown is a schematic structural diagram of a supercritical air-cooled steam turbine, which consists of a high-pressure cylinder 1 of a supercritical wet-cooled steam turbine, an intermediate-pressure cylinder 2 of a supercritical wet-cooled steam turbine, a low-pressure cylinder 3 of an air-cooled steam turbine, and a low-pressure cylinder 4 of an air-cooled steam turbine, and an intermediate-pressure cylinder 2 of a supercritical wet-cooled steam turbine It is connected with the low-pressure cylinder 3 of the air-cooled steam turbine, and between the low-pressure cylinder 3 of the air-cooled steam turbine and the low-pressure cylinder 4 of the air-cooled steam turbine by a floor bearing seat 6 .

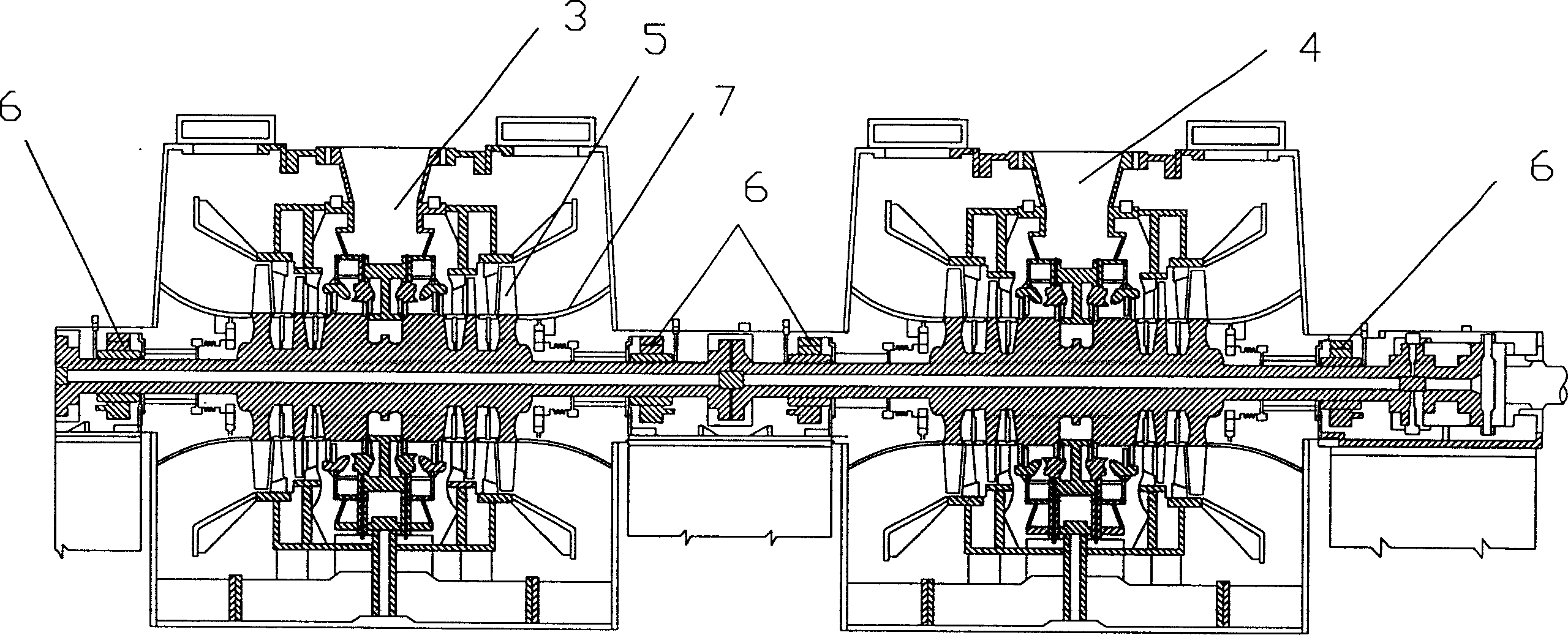

[0028] Such as image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com