Heat recovery system with multiple stages of deaerators

A heat recovery system and deaerator technology, applied in the direction of preheating, feed water heaters, chemical instruments and methods, etc., can solve the problems of increasing the initial investment of heater equipment, increasing the design parameters of high pressure heaters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

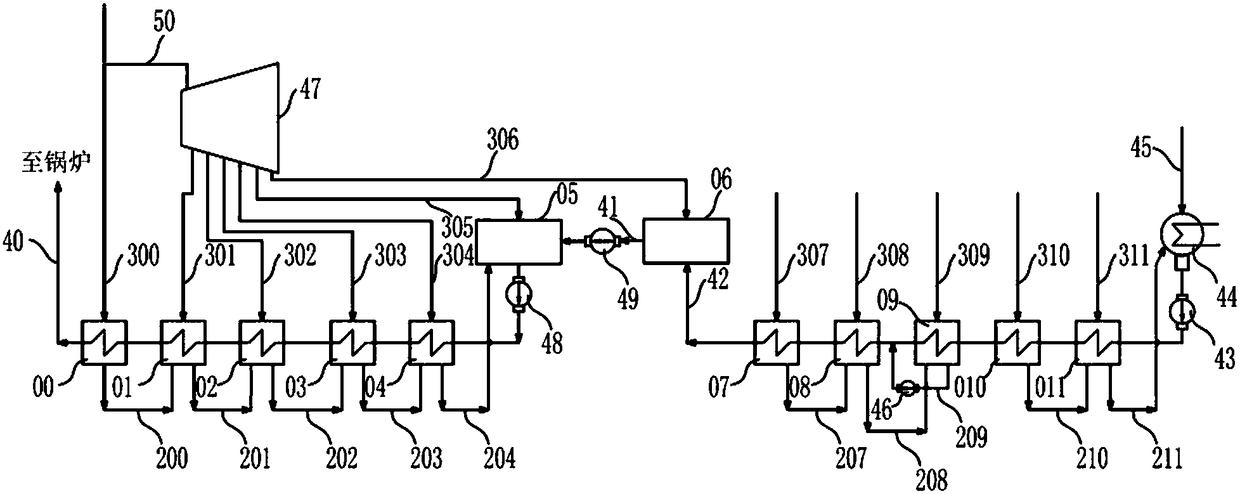

[0149] The figure of the recuperation system provided with the multi-stage deaerator of the present invention is as follows image 3 shown.

[0150] Such as image 3 As shown, the heat recovery system of the present invention includes a condenser 44, a condensed water pump 43, a low-pressure heater (surface heater), a low-pressure feed water pump 49, a high-pressure feed water pump 48, a BEST machine 47, a high-pressure heater (surface heater) device), high-pressure deaerator 05 (hybrid heater), low-pressure heater 06 (hybrid heater), condensate piping system, low-pressure water supply piping system, high-pressure water supply piping system, heater drain piping system (including drain pump 46). In this heat recovery system, the main steam turbine has 7 stages of extraction steam, of which the first stage extraction steam comes from the exhaust steam of the ultra-high pressure cylinder, which is divided into two routes, one is the main engine primary extraction steam 300 to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com