Thermal treatment process for erbium-containing aluminum-magnesium-manganese wrought aluminium alloy

A technology for deforming aluminum alloys and processes, which is applied in the field of heat treatment technology to achieve the effects of good strength, enhanced second-phase strengthening and dispersion strengthening, and stable mechanical properties and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Melting aluminum-magnesium-manganese alloys containing erbium, the mass percentage content of each component is Mg4.7%; Mn0.71%; Zr0.11%; Er0.31%; The amount is Al; the alloy is cast into an alloy ingot;

[0031] 2) Homogenize and anneal the alloy ingot, heat it at 280°C for 8 hours, and then hold it at 470°C for 10 hours;

[0032] 3) The homogenized annealed alloy is directly hot-rolled, always rolling along the width direction, about 4-20mm / pass, multi-pass; according to the hot rolling situation, it can be annealed again in the middle, the intermediate annealing temperature is 470 ° C, and the temperature is kept 1h;

[0033] 4) The hot-rolled sheet is cold-rolled to 1.5mm after about 0.5-1mm / pass, multi-pass;

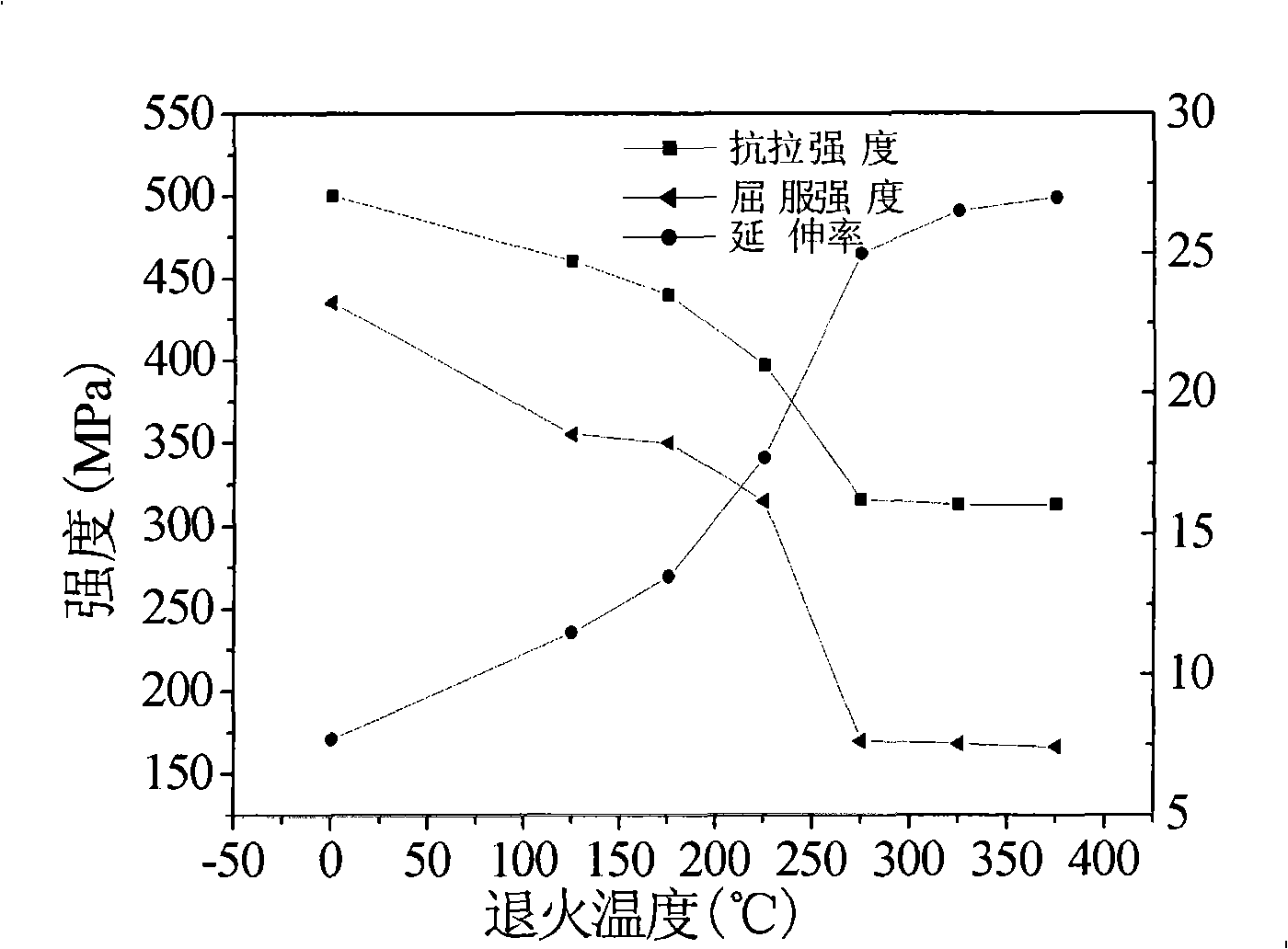

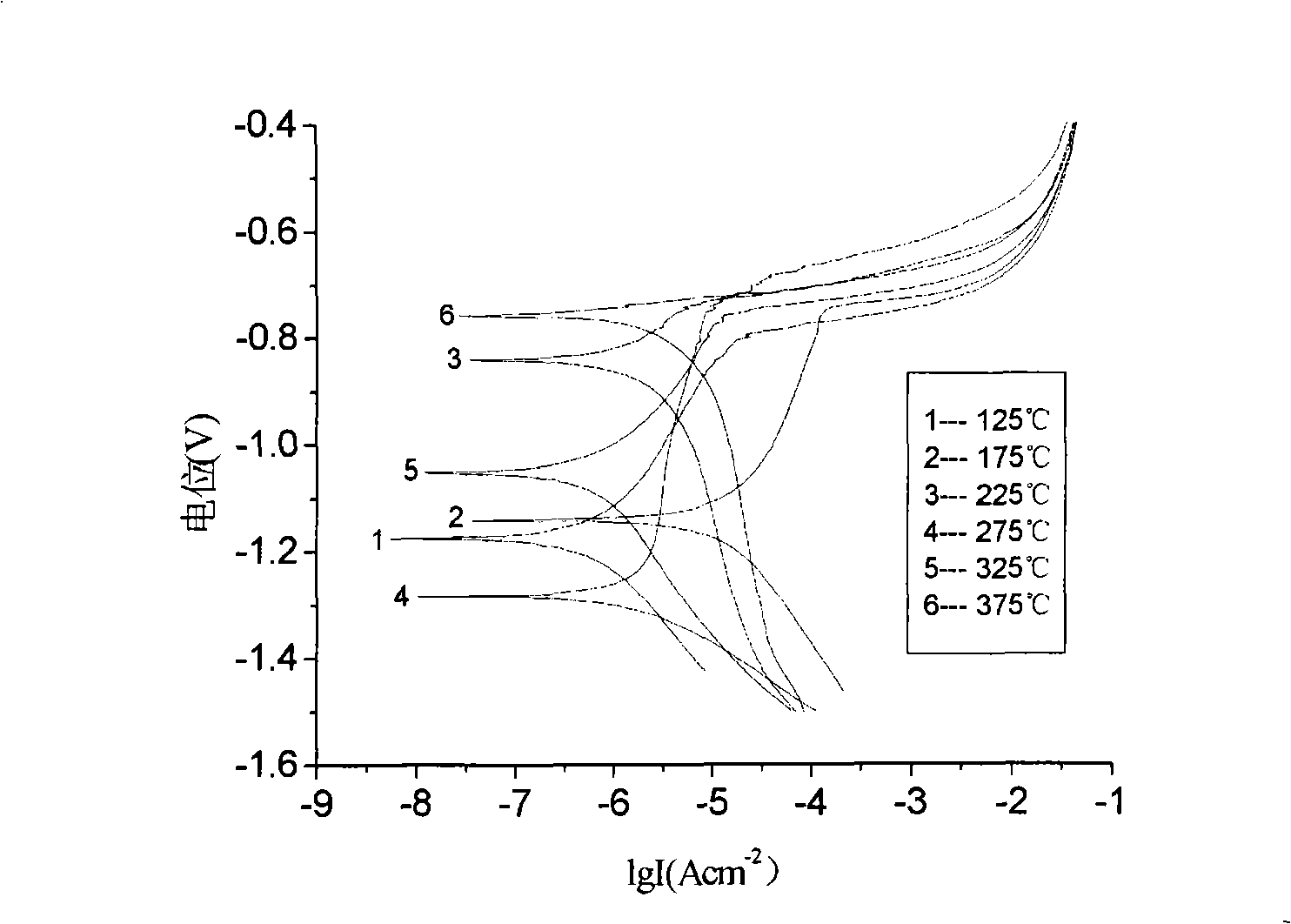

[0034] 5) Perform stabilization annealing on the cold-rolled sheet, keep it at 125-375° C. for 2 hours, and then air-cool to room temperature.

[0035] A total of 6 sets of experiments were carried out, and the alloy samples at different annealing tempe...

Embodiment 2

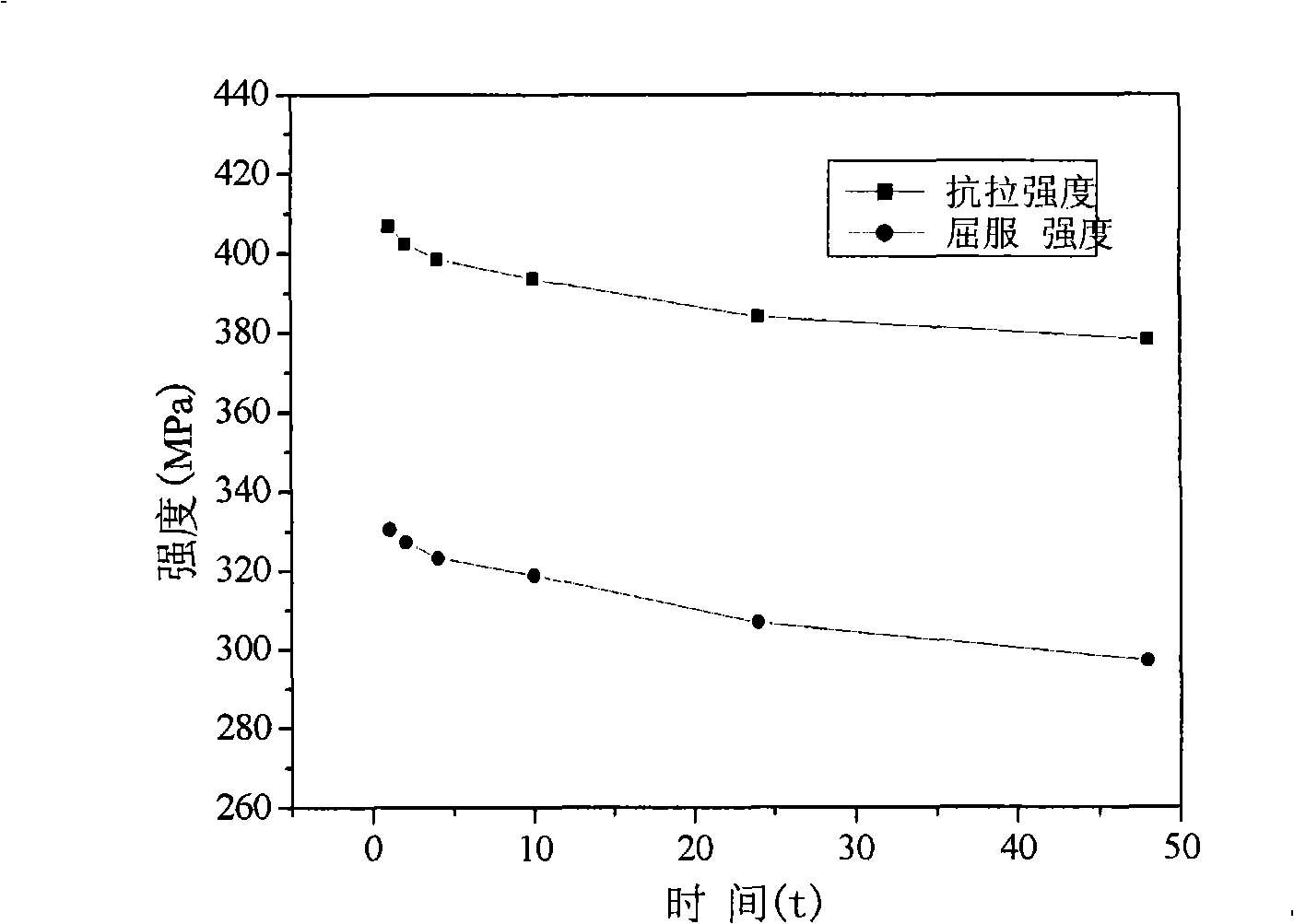

[0041] 1~4) synchronously with embodiment 1;

[0042] 5) Perform stabilization annealing on the cold-rolled sheet, anneal at 225° C., keep warm for 2 hours, and air-cool to room temperature. The cold-rolled sheet was stabilized and annealed at a temperature of 225°C. A total of 7 groups of experiments were carried out. The holding times were 1, 2, 4, 10, 24, and 48 hours, and air-cooled to room temperature.

[0043] The alloy samples with different annealing times were taken, and their mechanical properties and corrosion resistance were tested. The results are shown in Table 2.

[0044] Table 2Al-4.7Mg-0.7Mn-0.1Zr-0.3Er alloy

[0045] Mechanical properties and Tafel curve test results of annealing at 225°C for different annealing times

[0046] 225℃ / t

1

2

4

10

24

48

σ b

407

402

399

394

384

378

σ 0.2

331

327

323

318

307

301

δ

1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com