Parallel connection equipment opening type motion control card based on two-stage DSP and control method thereof

A motion control card and control card technology, applied in electric controllers, controllers with specific characteristics, program control, etc., can solve the problem that the working performance of parallel equipment is difficult to further improve, it is difficult to achieve high-speed and high-precision parallel equipment, and users cannot change it. Internal control algorithm and other issues to achieve the effect of reducing the pressure of data communication, improving the feed speed and positioning accuracy, and improving the dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described below in conjunction with accompanying drawing.

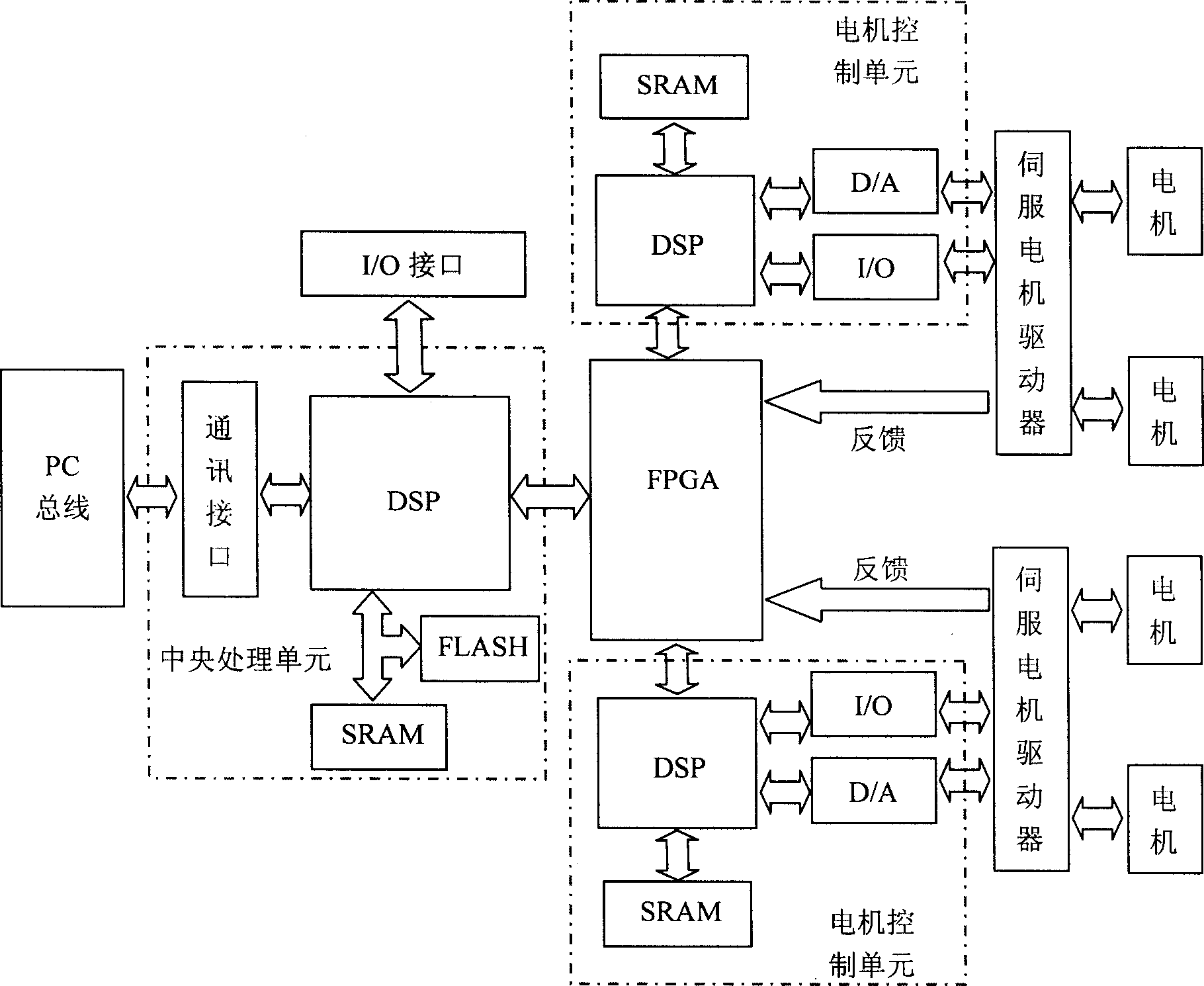

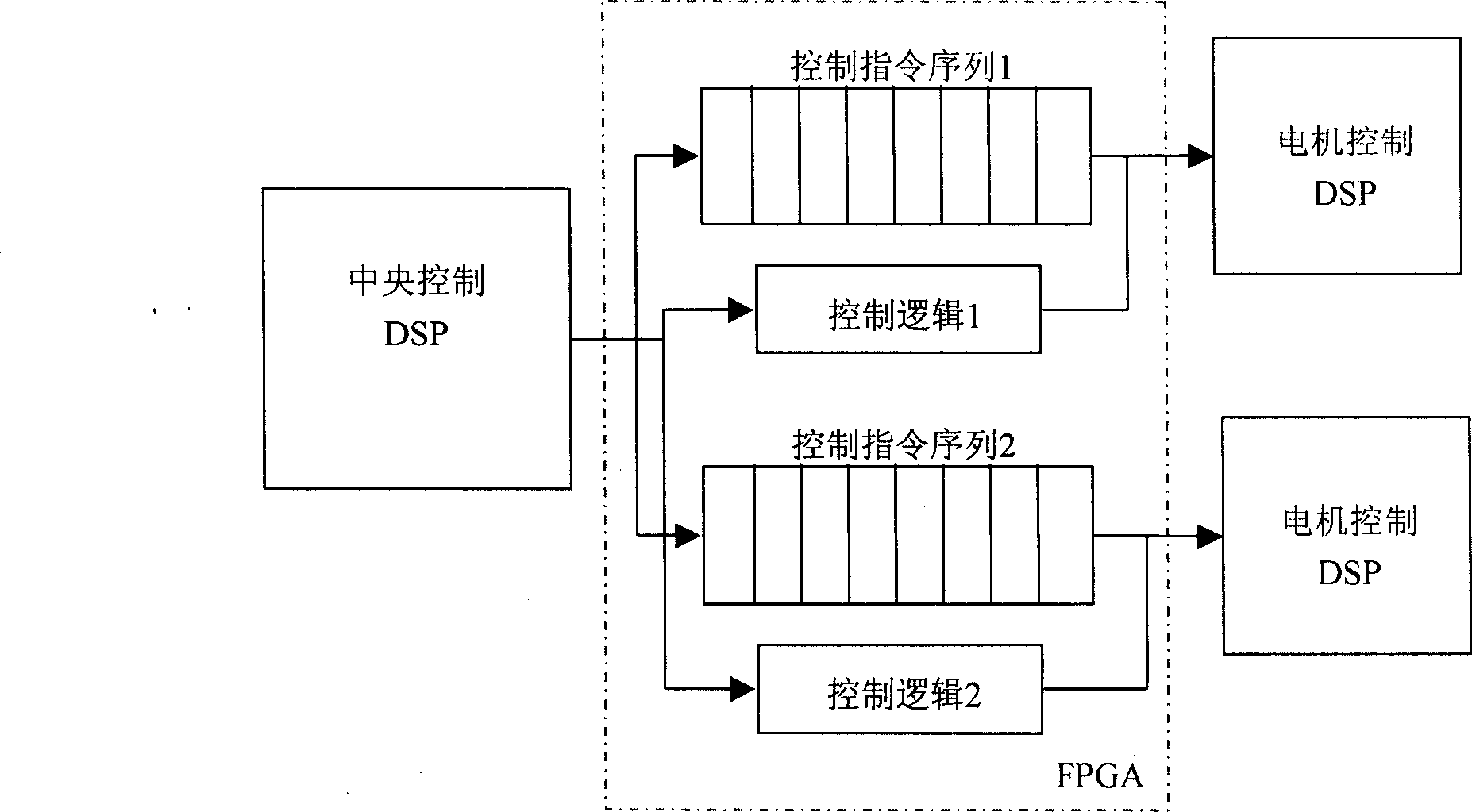

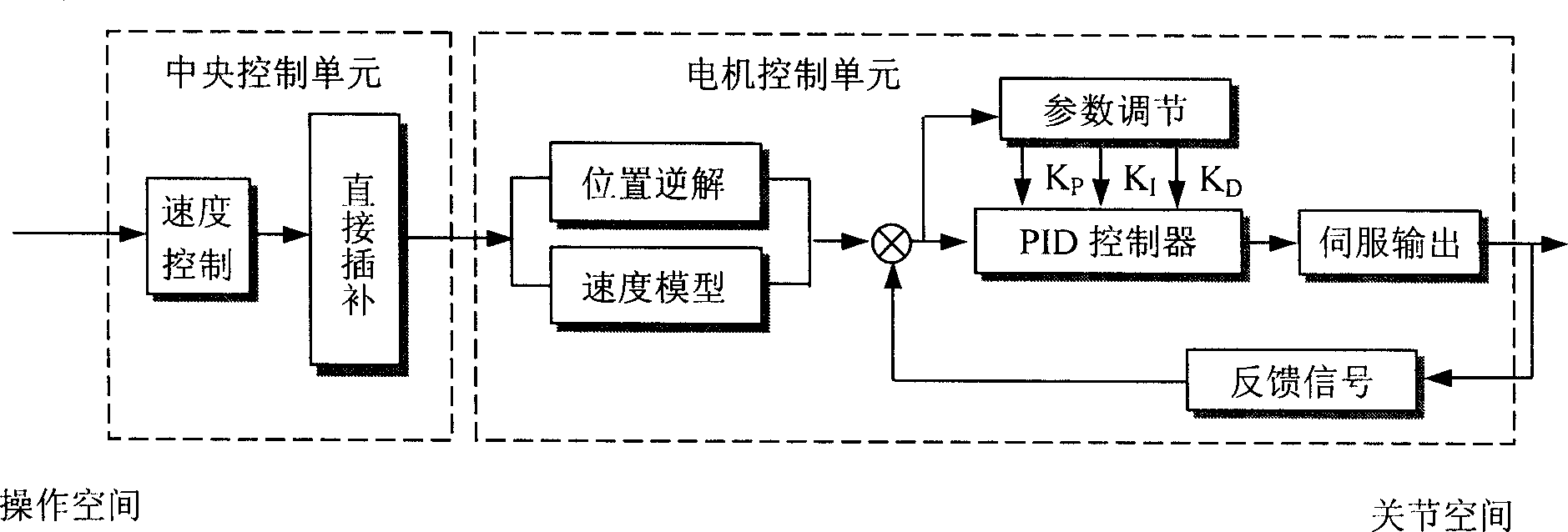

[0023] Depend on figure 1 Shown is the functional block diagram of the control card. The control card adopts a two-level control structure of multi-CPU parallel processing. The control level uses TI's DSP chip TMS320VC5402 as the central processing unit. TMS320C5402 can reach the command processing speed of 100MIPS, has more peripheral circuit interfaces and better data processing capabilities. The central processing CPU realizes the overall control of the system, including task scheduling, control decision-making, fault handling, error compensation, and calculation of motion trajectory in the operating space, such as trajectory interpolation and speed control of motion curves. Because the central processing CPU does not participate in the specific control of the motor, it only needs to complete the calculation and transmit the result to the motor control CPU, and does not need to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com