Small high-speed five-axis linkage machine tool

A five-axis linkage machine tool, high-speed technology, applied in the field of machine tools, can solve the problems of affecting the range of motion of the machine tool, occupying a large space of the machine tool, reducing the motion stroke, etc., so as to improve the machining accuracy and range, shorten the cutting processing time, eliminate The effect of overturning moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

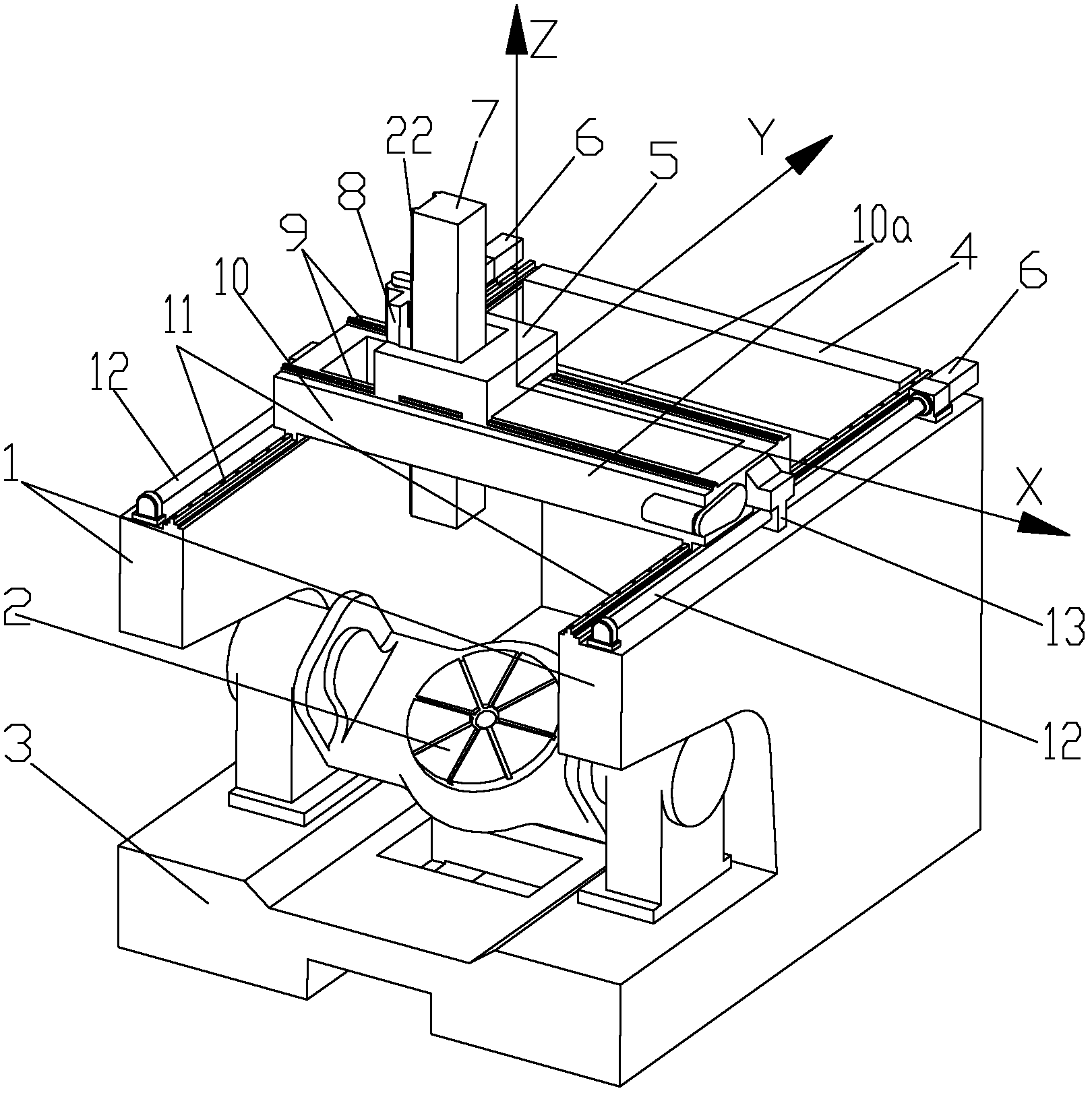

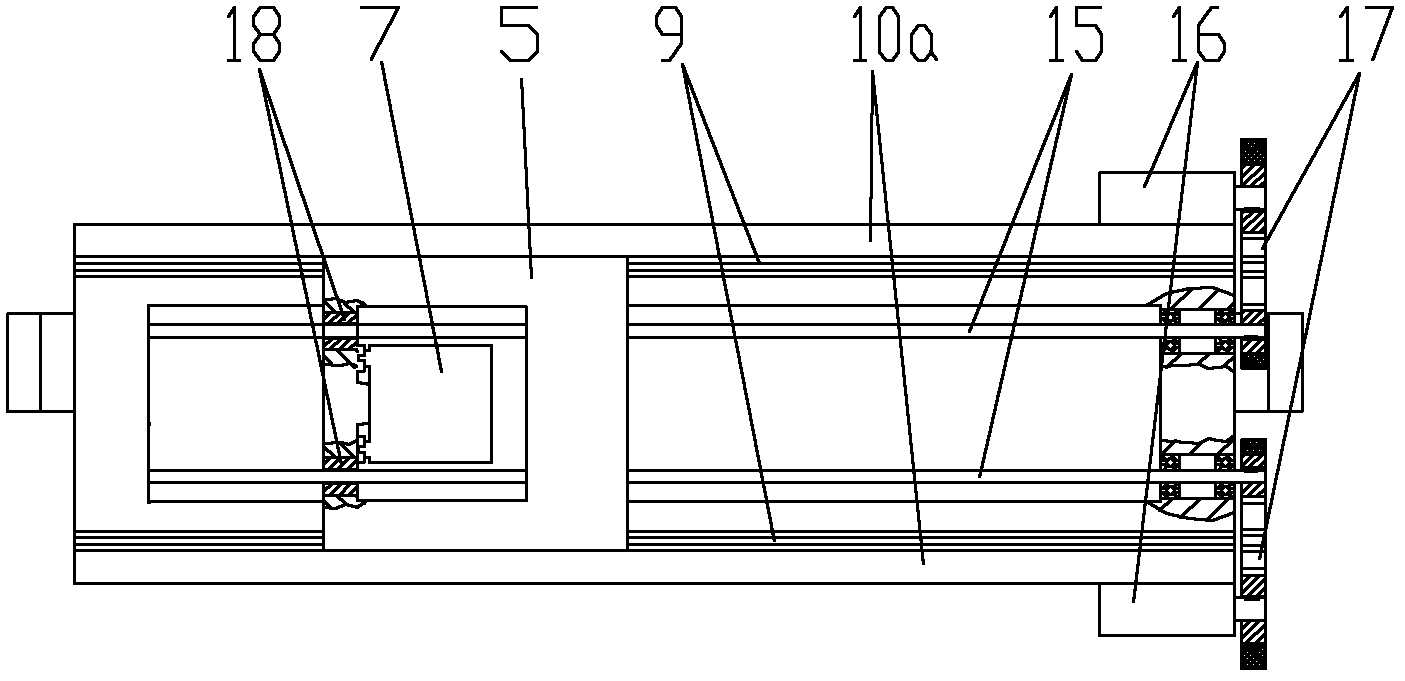

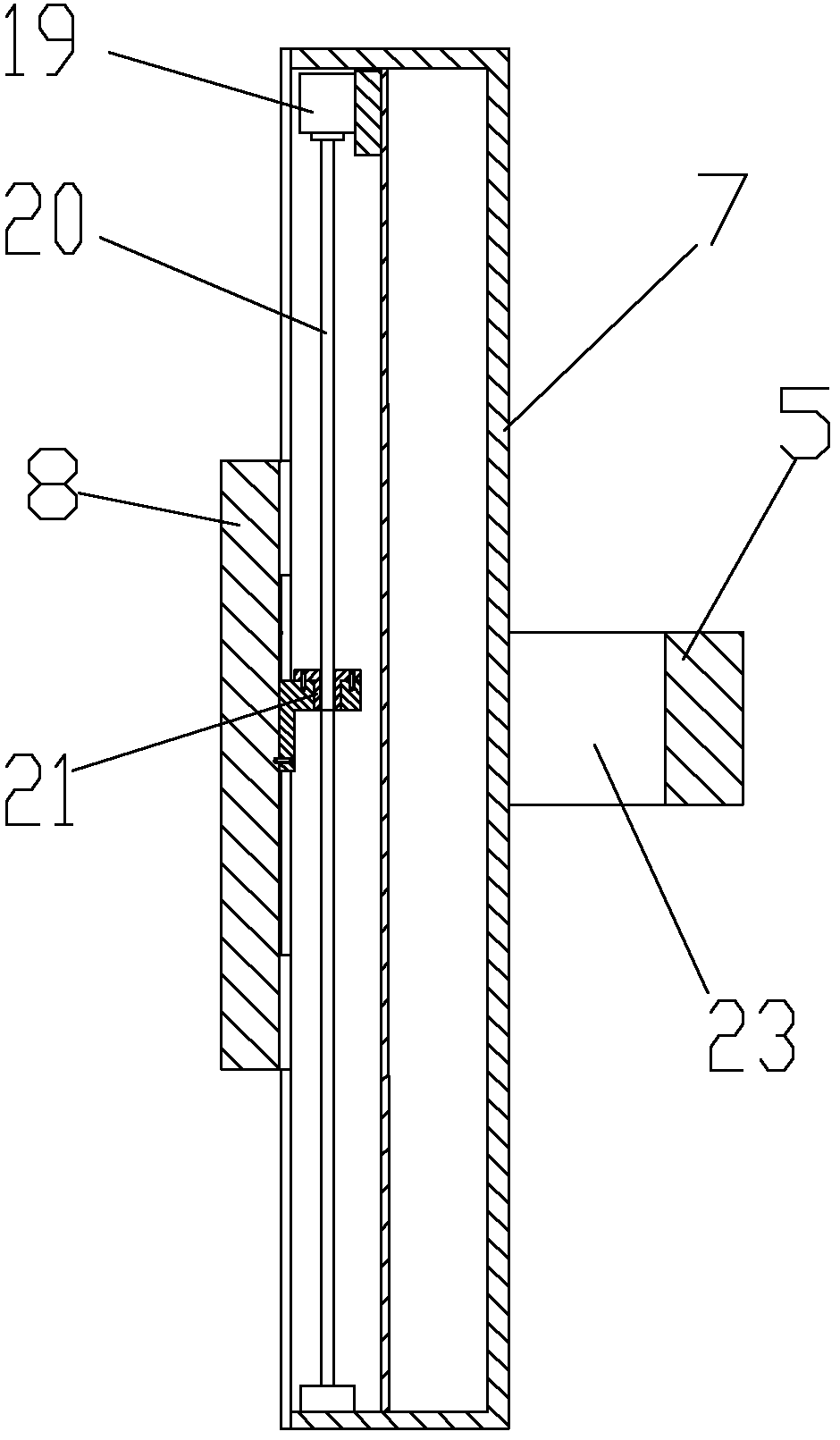

[0025] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the X-axis drive structure, image 3 It is a schematic diagram of the Z-axis drive structure, as shown in the figure: the small high-speed five-axis linkage machine tool of this embodiment includes a basic structure, a headstock assembly supported on the basic structure, and a cradle-type workbench 2;

[0026] The basic structure includes a machine tool base 3 and two columns 1 parallel and fixed on the base 3 along the X axis; it can be an integral structure, or can be formed by subsequent welding or connection;

[0027] The headstock assembly includes a Y-axis moving assembly, an X-axis moving assembly and a Z-axis moving assembly;

[0028] The Y-axis moving assembly includes a frame-shaped crossbeam 10 that spans between two columns 1 and can move back and forth in a single degree of freedom along the Y-axis direction and a Y-axis driving device for drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com