Metal ceramic combination binding agent and combination binding agent diamond wheel

A metal-ceramic composite and diamond grinding wheel technology, which is applied in the field of diamond grinding wheels, can solve the problems of high sintering temperature, inability to apply non-metal and non-ferrous metal materials, etc., and achieve excellent performance, good self-sharpening and high rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

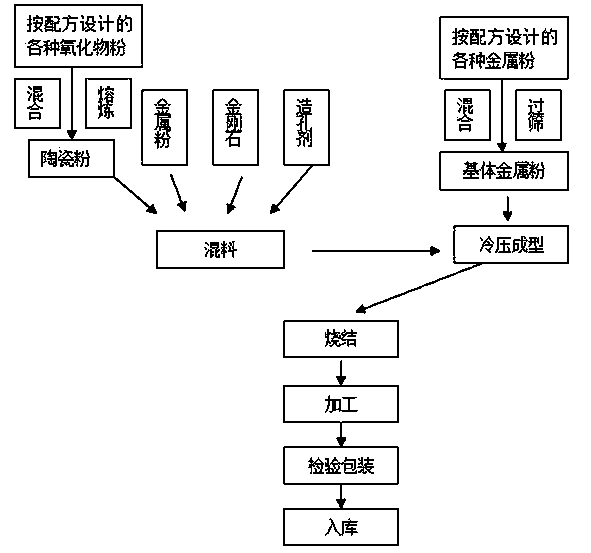

[0038] Embodiment one: see attached figure 1 , preparing a composite bond diamond grinding wheel, comprising the following steps:

[0039] 1. Preparation of ceramic powder:

[0040] Raw materials according to the following weight percentages: silicon dioxide SiO 2 55%, boron oxide B 2 o 3 25%, potassium oxide K 2 O 10%, magnesium oxide MgO 7.5%, calcium oxide CaO 2.5%, mixed and smelted to prepare ceramic powder;

[0041] The preparation steps are:

[0042] (1) Prepare mixed powder: mix and ball-mill the raw materials for preparing ceramic powder and pass through a 325-mesh standard sieve to obtain mixed powder;

[0043] (2) Melting glass: Melting the mixed powder prepared in step (1) in an electric furnace at 1700°C for 3 hours, and quenching to obtain a glass-ceramic block;

[0044] (3) Preparation of ceramic powder: crush the glass-ceramic block obtained in step (2) in a ball mill for 10 hours, and pass through a 325-mesh standard sieve to obtain ceramic powder.

...

Embodiment 2

[0051] Embodiment two: see attached figure 1 , prepare composite bond diamond grinding wheel, technological process is identical with embodiment one, specifically:

[0052] 1. Preparation of ceramic powder:

[0053] Raw materials according to the following weight percentages: silicon dioxide SiO 2 50%, boron oxide B 2 o 3 27%, potassium oxide K 2 O 15%, magnesium oxide MgO 5%, calcium oxide CaO 3%, mixed and smelted to prepare ceramic powder.

[0054] 2. Preparation of composite bond diamond grinding wheel:

[0055] (1) The raw materials with the following weight ratio: 663 bronze powder 80%, ceramic powder 20%, ball milled in a planetary vacuum ball mill for 20 hours, the mixture was placed in a vacuum box for 24 hours, and then taken out through a 325-mesh standard sieve , to obtain a composite binder. Put the obtained composite binder and diamond abrasive into a planetary vacuum ball mill and mix evenly, then pass through a 200-mesh standard sieve, add a pore-formi...

Embodiment 3

[0060] Embodiment three: see attached figure 1 , prepare composite bond diamond grinding wheel, technological process is identical with embodiment one, specifically:

[0061] 1. Preparation of ceramic powder:

[0062] Raw materials according to the following weight percentages: silicon dioxide SiO 2 45%, boron oxide B 2 o 3 27%, potassium oxide K 2 O 13%, magnesium oxide MgO 10%, calcium oxide CaO 5%, mixed and smelted to prepare ceramic powder.

[0063] 2. Preparation of composite bond diamond grinding wheel:

[0064] (1) The raw materials with the following weight ratio: 60% of 663 bronze powder and 40% of ceramic powder were ball milled in a planetary vacuum ball mill for 20 hours. , to obtain a composite binder. Put the obtained composite binder and diamond abrasive into a planetary vacuum ball mill and mix evenly, then pass through a 200-mesh standard sieve, add a pore-forming agent, and then pass through a 200-mesh standard sieve to obtain a grinding wheel mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com