Carbon fiber composite rotary ultrasonic milling and grinding device and method

A composite material and rotary ultrasonic technology, which is applied in the field of carbon fiber composite material rotary ultrasonic milling and grinding, can solve the problems of blockage of grinding wheel holes, poor thermal conductivity, and inability to carry out liquid cooling, and achieve the effect of ensuring machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

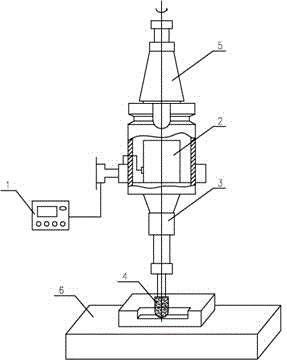

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] A carbon fiber composite material rotary ultrasonic milling device, which is composed of an ultrasonic generator 1, an ultrasonic transducer 2, a horn 3, a tool 4, a tool handle 5, and a machine tool body 6;

[0023] The ultrasonic generator 1 is connected with the ultrasonic transducer 2; the ultrasonic transducer 2 is connected with the horn 3; the horn 3 is connected with the cutter 4; the ultrasonic vibration device is connected with the cutter The handle 5 is connected; the ultrasonic vibration device is installed above the machine tool body 6 .

[0024] A carbon fiber composite material rotary ultrasonic milling processing method, comprising the following steps:

[0025] The high-frequency electrical oscillation is generated by the ultrasonic generator and applied to the ultrasonic transducer to convert the high-frequency electrical oscillation into ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com