Beta-naphthol produced waste liquid modified amido sulfoacid series high-efficiency water reducer and preparation method thereof

A sulfamic acid-based, high-efficiency water-reducing agent technology, applied in the field of building materials, to achieve good workability, easy control of reaction conditions, and obvious enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

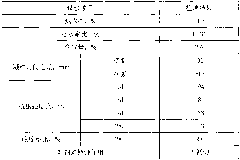

[0020] The preparation process steps of the preparation method of the high-efficiency water reducer are as follows: each process step is carried out under normal pressure.

[0021] (1) Sulfonation reaction: first add β-naphthol production waste liquid into the reaction kettle, heat it to 105-110°C, add concentrated sulfuric acid dropwise, drop it in 15-30 minutes, and keep it warm for 1.5-2.5 hours to obtain naphthol Sulfonate.

[0022] (2) Polycondensation reaction: Heat water to 65-75°C, add sodium p-aminobenzenesulfonate, phenolic compounds and about three-quarters of the total amount of pH regulator into the reaction kettle, and heat up to 80-90°C; add formaldehyde dropwise, finish dropping within 10-30 minutes, and keep the temperature between 85-95°C, keep warm for 2-5 hours; add the remaining pH regulator and naphthol obtained in step (1) The sulfonate is reacted at 85-95° C. for 1.5-2.5 hours, and then cooled and discharged to obtain a liquid product. The above liqui...

Embodiment 1

[0034] The preparation process of the present invention comprises two steps, and each process step is all carried out under normal pressure:

[0035] (1) Sulfonation reaction: Put 480 kg of β-naphthol production waste liquid into the reaction kettle, heat it to 110°C, add 120 kg of concentrated sulfuric acid dropwise, drop it in 15 minutes, and keep it warm for 2 hours to obtain naphthol sulfonate .

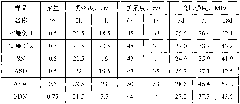

[0036] (2) Polycondensation reaction: Heat water to 70°C, add 419 kg of sodium p-aminobenzenesulfonate, 475 kg of phenol and 75 kg of sodium hydroxide into the reaction kettle, heat up to 85°C while stirring; add 720 kg of formaldehyde dropwise , dripped within 20 minutes, and kept the temperature at 95°C for 2.5 hours; added the remaining 30 kg of sodium hydroxide and the naphthol sulfonate obtained in step (1), reacted at 95°C for 1.5 hours, then cooled and discharged , that is, a liquid product is prepared. The above-mentioned liquid product is then spray-dried to obtain a p...

Embodiment 2

[0038] The preparation process of the present invention comprises two steps, and each process step is all carried out under normal pressure:

[0039] (1) Sulfonation reaction: put 390 kg of β-naphthol production waste liquid into the reaction kettle, heat it to 105°C, add 114 kg of concentrated sulfuric acid dropwise, drop it in 15 minutes, and keep it warm for 2 hours to obtain naphthol sulfonate .

[0040] (2) Polycondensation reaction: Heat water to 70°C, add 405 kg of sodium p-aminobenzenesulfonate, 526 kg of bisphenol A, 12 kg of calcium hydroxide and 60 kg of potassium hydroxide into the reaction kettle, and heat up to 85°C; add 685 kg of formaldehyde dropwise, drop it within 20 minutes, and keep the temperature at 90°C for 3 hours; add the remaining 33 kg of potassium hydroxide and the naphthol sulfonate obtained in step (1), at 95°C After reacting for 2 hours, the temperature was lowered and the material was discharged to obtain a liquid product.

[0041] The followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com