Recycled green concrete with low cement content and preparation method thereof

A concrete and green technology, applied in the field of building materials, can solve the problems of high cost, high cement consumption, and the inability to implement technical and economic policies for resource conservation and environmental protection, and achieve resource consumption, effective utilization, and high density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

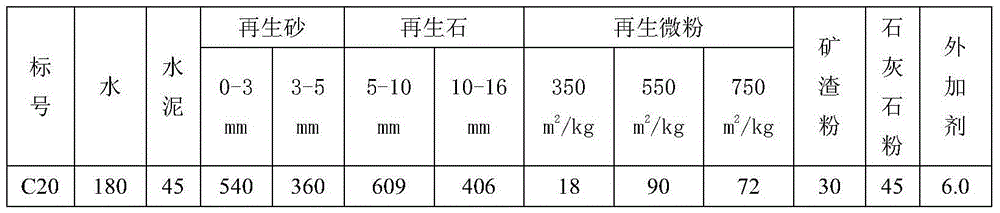

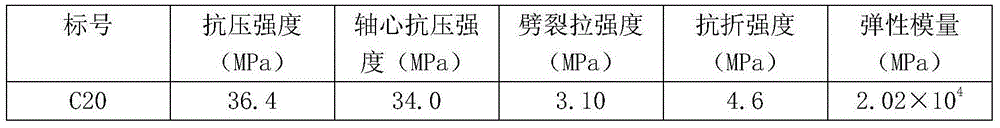

[0027] Prepare recycled green concrete with strength class C20. The cementitious material contains 15% of cement, 60% of recycled micropowder, 10% of slag powder, and 15% of limestone powder. The particle size ratio of 5mm~10mm and 10mm~16mm is 6:4; the specific surface area is 350m 2 / kg, 550m 2 / kg, 750m 2 / kg of regenerated micropowder according to the ratio of 1:5:4, according to the mix ratio in Table 1, the sand rate is 47%, the water-cement ratio is 0.6, weigh cement, regenerated sand, regenerated stone, slag powder, regenerated micropowder, limestone powder, Put in regenerated sand, regenerated stone and 2∕5 of water and stir for 10 seconds; put in cement, regenerated micropowder, slag powder, limestone powder, admixture and the remaining 3∕5 of water and continue stirring until the machine is evenly discharged. The mixing time from the regenerated sand and regenerated stone into the mixer to the concrete output is 100-120 seconds.

[0028] Table 1 Mixing ratio of ...

Embodiment 2

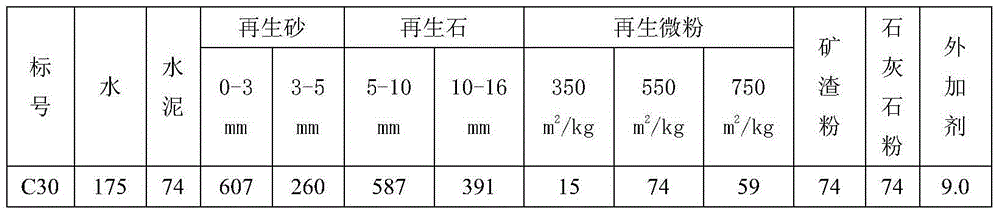

[0035] Prepare recycled green concrete with strength class C30. The cementitious material contains 20% of cement, 40% of recycled micropowder, 20% of slag powder, and 20% of limestone powder. The ratio of fine sand with a particle size of 0mm to 3mm and a particle size of 3mm to 5mm in the recycled sand is 7:3; recycled stone The particle size ratio of 5mm~10mm and 10mm~16mm is 6:4; the specific surface area is 350m 2 / kg, 550m 2 / kg, 750m 2 / kg of regenerated micropowder according to the ratio of 1:5:4, according to the mix ratio in Table 3, the sand ratio is 47%, the water-cement ratio is 0.47, weigh cement, regenerated sand, regenerated stone, slag powder, regenerated micropowder, limestone powder, Put in regenerated sand, regenerated stone and 2∕5 of water and stir for 10 seconds; put in cement, regenerated micropowder, slag powder, limestone powder, admixture and the remaining 3∕5 of water and continue stirring until the machine is evenly discharged. The mixing time fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com