Composite material section bar as well as preparation method and application thereof in preparation of solar photovoltaic module

A composite material and profile technology is applied in the application field of preparing solar photovoltaic modules, which can solve the problems of reducing the service life of photovoltaic modules, limiting the application of solar cells, and being easy to corrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

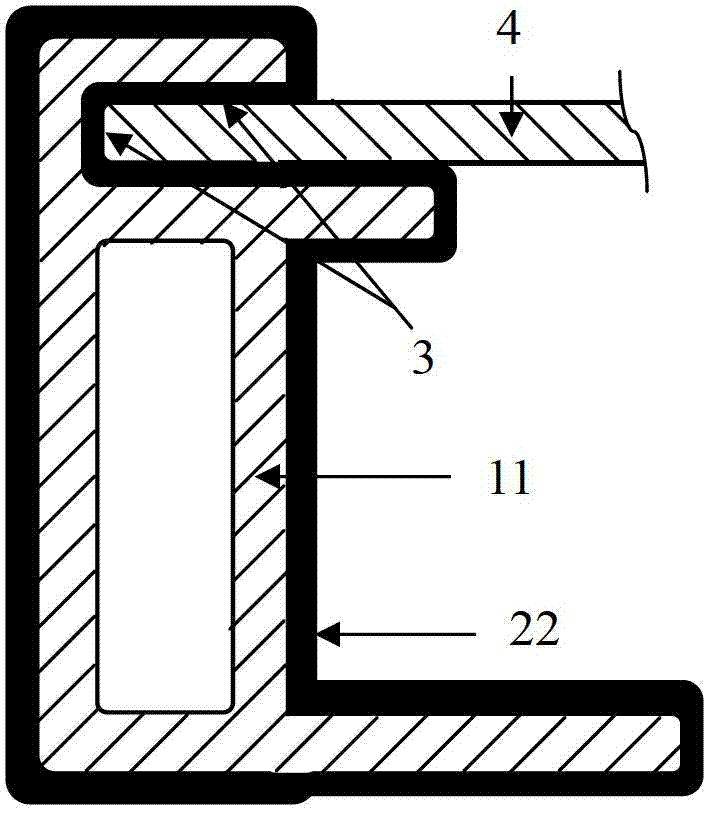

[0027] like Figure 1-2 As shown, a FRP profile for photovoltaic modules is used to make the frame of photovoltaic modules. figure 2 is the frame diagram of the photovoltaic module, figure 1 Yes figure 2 Schematic diagram of the 1-1 section of the frame 12 of the middle component. In this embodiment, unidirectional glass fiber, unidirectional carbon fiber, glass fiber plain woven fabric, carbon fiber plain woven fabric and phenolic resin are obtained by pultrusion according to the mass ratio of 3 / 1 / 3 / 1 / 2.

[0028] The tensile strength and bending strength of the profile are both up to 250MPa, reaching the mechanical performance index of ordinary aluminum alloy profiles.

[0029] The wall thickness of the profile is about 2mm everywhere.

[0030] The profile has a density of 1.80g / mm 3 , has the characteristics of light weight.

[0031] Among them, the profile wall 11 is made of unidirectional glass fiber and unidirectional carbon fiber, and the profile wall 22 is made ...

Embodiment 2

[0035] like Figure 1-2 As shown, a FRP profile for photovoltaic modules is used to make the frame of photovoltaic modules. figure 2 is the frame diagram of the photovoltaic module, figure 1 Yes figure 2 Schematic diagram of the 1-1 section of the frame 12 of the middle component. In this embodiment, the mixed fiber plain weave fabric of unidirectional glass fiber, unidirectional aramid fiber, glass fiber twill woven fabric, carbon fiber and polyimide fiber and epoxy resin are according to the quality of 1 / 1 / 2 / 2 / 4 Ratio Composite profiles obtained by pultrusion, wherein the mixing ratio of carbon fiber and polyimide fiber is 1:1.

[0036] The tensile strength and bending strength of the profile are both up to 200MPa, reaching the mechanical performance index of ordinary aluminum alloy profiles.

[0037] The wall thickness of the profile is about 2mm everywhere.

[0038] The profile has a density of 1.80g / mm 3 , has the characteristics of light weight

[0039] Among th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com