Wet-process substrate non-woven fabric used for reverse osmosis membrane and preparation method thereof

A technology of reverse osmosis membrane and non-woven fabric is applied in the field of preparation of the base non-woven fabric, and can solve the problems of inability to meet the use requirements of reverse osmosis membrane, insufficient structure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

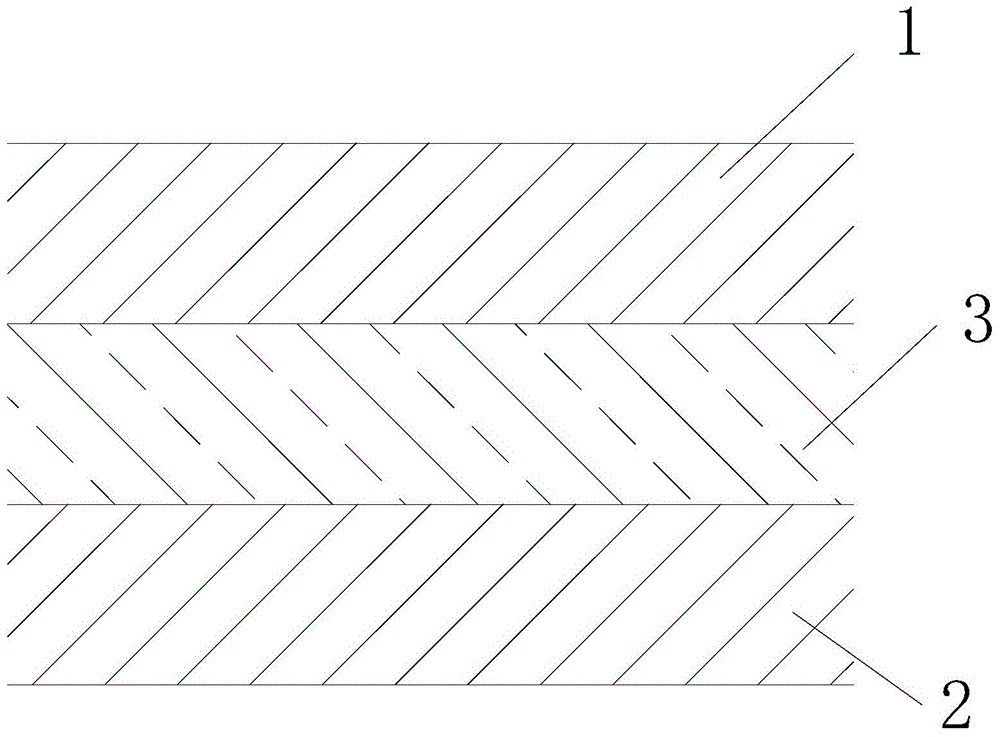

[0069] Example 1, see attached figure 1

[0070] A non-woven base material used for wet sheeting of reverse osmosis membranes, which is made of synthetic fibers after wet sheeting and hot-melt rolling, and its:

[0071] a, the substrate non-woven fabric has a single-layer structure as a whole;

[0072] b, the substrate non-woven fabric with a single-layer structure as a whole, which is composed of synthetic fibers of different raw materials in the upper, middle and lower layers;

[0073] And its upper layer is a low-melting point hot-melt ES composite fiber 1, and the ES composite fiber is a concentric circular fiber composed of surface layer PE polyethylene and inner core PP polypropylene;

[0074] And its lower layer is low-melting-point hot-melt COPET / PET polyester composite fiber 2, and the COPET / PET polyester composite fiber is a concentric circular fiber composed of surface-modified COPET low-melting-point polyester and inner core PET polyester;

[0075] And the middl...

Embodiment 2

[0082] Example 2: See attached figure 1 :

[0083] A method for preparing the above-mentioned substrate non-woven fabric, using synthetic fibers meeting the technical requirements claimed in Example 1 as a raw material, and using a wet papermaking machine as a process equipment, the preparation steps include:

[0084]a. Hydrophilic pretreatment of raw fiber: first use tap water and high-efficiency hydrophilic penetrating agent to mix and prepare circulating water for hydrophilic papermaking at a weight ratio of 1000:4. The raw material fibers were weighed according to the following proportions by weight: 10.5 kg of ES fibers (20 μm in diameter and 4 mm in length). Accounting for 35%; COPET / PET fiber (diameter 15μm, length 4mm) 10.5kg, accounting for 35%; PET ultrafine fiber (diameter 5μm, length 2.5mm) 9kg, accounting for 30%. Put the weighed raw fiber into a beater, add water, mix and beat. The weight ratio of water and fiber in the beater cylinder is 12:1. Put the beaten...

Embodiment 3

[0091] Embodiment 3: A kind of preparation method of described substrate nonwoven fabric is carried out according to the following steps

[0092] In step a, tap water and high-efficiency hydrophilic penetrating agent are mixed at a weight ratio of 1000:4 to make hydrophilic circulating water. Weigh the raw material fibers according to the following proportions: ES fiber (diameter 18μm, length 3mm) 9.1kg, accounting for 33%; COPET / PET fiber (diameter 12μm, length 4mm) 9.6kg, accounting for 35%; PET ultrafine fiber (diameter 5μm, length 3mm) ) 8.8kg, accounting for 32%. Hydrophilic papermaking circulating water and total fiber weight ratio is 1000:1.1. Put the weighed fiber into the beater for mixing and beating. The weight ratio of water and fiber in the tank of the beater is 12:1. Put the fiber slurry after beating and mixing into the hydrophilic papermaking circulating water in the slurry storage tank, turn on the mixer to dilute and disperse until the fiber is in a single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com