High-performance continuous synthetic fiber reinforced thermoplastic composite and preparation method thereof

A technology for reinforcing thermoplastic and continuous fibers, which is used in the field of thermoplastic composite materials to achieve the effects of reducing cost, improving reinforcement effect, and improving impact resistance and fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

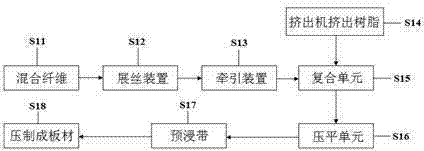

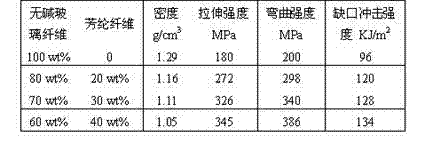

[0030] Production process such as figure 1 As shown, the alkali-free glass fiber and aramid fiber are placed on the creel (S11) according to the different weight ratios shown in Table 2, and are introduced from the creel into the spreading device (S12), and then drawn by the pulling device The continuous fiber tape (S13) which is evenly mixed with alkali-free glass fiber and aramid fiber is obtained by spreading evenly under the bottom, and then it is preheated by the infrared heating system and then introduced into the double extrusion die head. The preheating temperature is 200 ° C, and the preheating time is 8s. The matrix resin is selected as polypropylene, and the auxiliary agent is compatibilizer PP-g-MAH. Through the method of extrusion coating, the modified resin is melt-extruded (S14) with double extrusion dies and the continuous fiber tape is pre-processed. Impregnation, composite molding at the composite unit (S15), the continuous fiber tape is flattened (S16), coo...

Embodiment 2

[0033] The reinforcing fibers in Example 2 are alkali-free glass fibers and ultra-high molecular weight polyethylene fibers; other operating procedures and test methods are the same as in Example 1, and the test results are listed in Table 3.

Embodiment 3

[0035] In Example 3, the reinforcing fibers are alkali-free glass fibers and aramid fibers; the matrix resin is nylon 6; the auxiliary agents are antioxidant 1010 and antioxidant 168. Other operation process and test method are identical with embodiment 1, and test result is listed in table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com