Preparation method of mixed fiber system aramid paper

A technology of mixed fiber and aramid paper, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material treatment, papermaking, etc., and can solve problems such as fiber flocculation, poor paper formation, and poor paper strength , to achieve the effect of improving paper evenness, reducing the ratio and avoiding flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

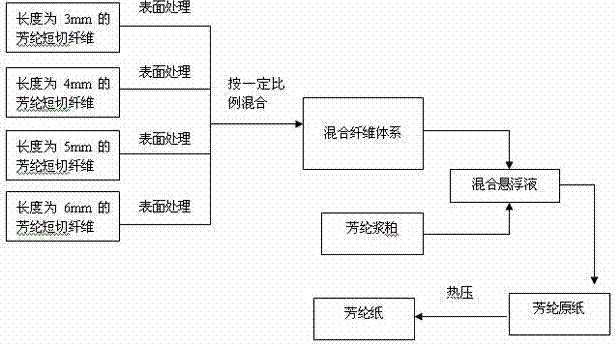

[0030] A method for preparing an aramid paper of a mixed fiber system, comprising the following steps:

[0031] 1), the molar concentration will be 1.5×10 -3 -3.0×10 -3 mol / L sodium dodecylbenzene sulfonate solution, under the condition of 40-60 ℃, constant temperature treatment of two or more kinds of aramid chopped fibers of different lengths for 0.5h-1h, mixed according to different proportions to obtain mixed fiber system,

[0032] 2) Mix 30-50 parts by mass of the mixed fiber system in step 1) with 50-70 parts by mass of aramid pulp, and then disintegrate and disperse in the fiber dissociation machine; add 4-6mL of poly Ethylene oxide solution to obtain a mixed suspension of mixed fiber and aramid pulp, the sum of the mass parts of the mixed fiber system and aramid pulp is 100;

[0033] 3) Pour the mixed suspension into the sheet former for dehydration and forming, then wet press to remove excess water, and finally dry.

[0034] 4) The prepared aramid paper is subject...

Embodiment 1

[0036] A method for preparing aramid paper with mixed fiber system, comprising the following steps:

[0037] 1) Use aramid chopped fibers with a length of 3mm and 6mm at a molar concentration of 1.5×10 -3 The mol / L sodium dodecylbenzenesulfonate solution was soaked at 40°C for 0.5h;

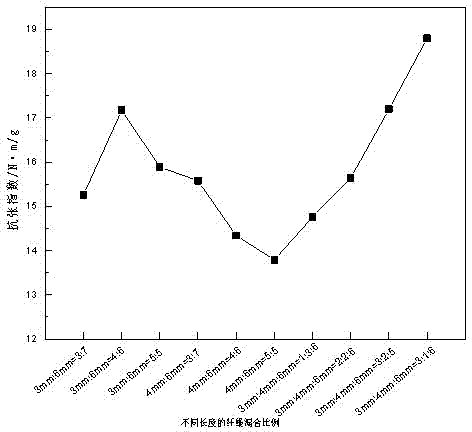

[0038] 2) Mix the soaked aramid chopped fibers with a length of 3 mm and 6 mm in a ratio of 4:6 to obtain a mixed fiber system.

[0039] 3) Mix 30 parts by mass of the mixed fiber system with 70 parts by mass of aramid pulp, then disintegrate and disperse in a fiber dissociation machine, add 4mL of PEO (polyethylene oxide) solution during the dispersion process, and obtain a mixed suspension , the sum of the mass parts of the two raw materials is 100.

[0040] 4) Pour the mixed suspension into the sheet former for dehydration and forming, then wet press to remove excess water, and finally dry.

[0041] 5) The prepared aramid paper is subjected to high-temperature hot-pressing treatment on a ho...

Embodiment 2

[0043] A method for preparing aramid paper with mixed fiber system, comprising the following steps:

[0044] 1) Use aramid chopped fibers with a length of 4mm and 6mm at a molar concentration of 2.0×10 -3 The mol / L sodium dodecylbenzenesulfonate solution was soaked for 45min at 50°C;

[0045] 2) Mix the soaked aramid chopped fibers with a length of 4 mm and 6 mm in a ratio of 4:6 to obtain a mixed fiber system with an average length of 5 mm.

[0046] 3) Take 40 parts by mass of the mixed fiber system with an average length of 5mm and mix it with 60 parts by mass of aramid pulp, and then disintegrate and disperse in the fiber dissociation machine. During the dispersion process, 5 mL of PEO solution was added to obtain a mixed suspension, and the sum of the mass parts of the two raw materials was 100.

[0047] 4) Pour the mixed suspension into the sheet former for dehydration and forming, then wet press to remove excess water, and finally dry.

[0048] 5) The prepared aramid pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com