Prepn process of polyimide microsphere

A technology of polyimide microspheres and polyamic acid, which is applied in the field of preparing polyimide microspheres from monomers in solution by dispersion polymerization, can solve the problem of poor control of particle shape and particle size distribution. Easy to degrade imide, high cost, low solubility of polyimide, etc., to achieve the effect of mild implementation conditions, increased yield, and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

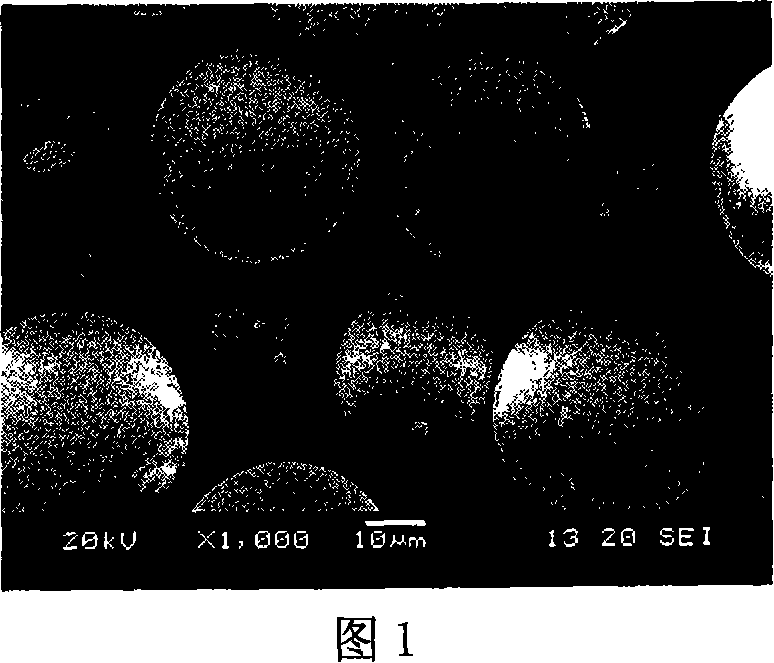

Image

Examples

example 1

[0037] Example 1: In a 1 L three-necked flask, 19 g of 1,3-bis(3-aminophenoxy)benzene BAPB (commercially available) was dissolved in 160 g of NMP, and stirred until completely dissolved. Add about 20g of PVA into this homogeneous solution, stir and dissolve evenly. Add 21 g of triphenyl ether tetra-acid dianhydride HQDPA (commercially available) in three times, add 0.2 g of phthalic anhydride after polymerization, and polymerize at 60°C for four hours to obtain a polyamide with a solid content of 20%. Acid solution 200g. Then according to the process conditions, 2.37 g of triethylamine catalyst and 10.6 g of dehydrating agent acetic anhydride were sequentially added for chemical imidization. After the stirring reaction is complete, 400 g of an aqueous solution of PVA with a mass concentration of 10% is prepared and added dropwise to the imidized reaction system. The aqueous solution of the dispersant needs to be added after the previous solution is completely dissolved, unti...

example 2

[0038] Example 2: In a 500 mL open beaker, 35 g of diaminotriphenylamine DATPA (commercially available) was dissolved in 90 g of DMAc, and stirred until completely dissolved. Add about 5g of PVA into this homogeneous solution, stir and dissolve evenly. Add 5.12 g of 3,3,4,4,-biphenyltetracarboxylic dianhydride (commercially available) BPDA (commercially available) in four times, and polymerize for four hours in a water bath at 70°C to obtain 100 g of a polyamic acid solution with a solid content of 10%. . Then, 1.4 g of pyridine catalyst and 3.6 g of dehydrating agent acetic anhydride were sequentially added according to the process conditions for chemical imidization. After complete stirring, 300 g of an aqueous solution of PVA with a mass fraction of 3% was prepared and added dropwise to the imidized reaction system. The aqueous solution of the dispersant needs to be added after the previous solution is completely dissolved, until the precipitate no longer disappears, cont...

example 3

[0039] Example 3: In a 1 L three-necked flask, 19 g of 1,3-bis(3-aminophenoxy)benzene BAPB (commercially available) was dissolved in 160 g of NMP, and stirred until completely dissolved. Add about 10g of PVP into this homogeneous solution, stir and dissolve evenly. Add 21g of triphenyl ether tetra-acid dianhydride HQDPA (commercially available) in three times, add 0.2g of phthalic anhydride after polymerization, and polymerize at 60°C for five hours to obtain a polyamide with a solid content of 20%. Acid solution 200g. Then, 4.2 g of pyridine catalyst and 10.6 g of dehydrating agent acetic anhydride were sequentially added according to the process conditions for chemical imidization. Stir to complete the reaction. Prepare 400 g of an aqueous solution of PVP with a mass fraction of 10%, and add it dropwise into the imidized reaction system. The aqueous solution of the dispersant needs to be added after the previous solution is completely dissolved, until the precipitate no l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com