Structural color film material and method for preparing same

A technology of structural color and film materials, which is applied in the field of structural color film materials, preparation of structural color film materials, and structural color film materials used in large areas, and can solve the problems of difficult to obtain monodisperse colloid, time-consuming, and low photonic crystal strength and other problems, to achieve the effect of simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

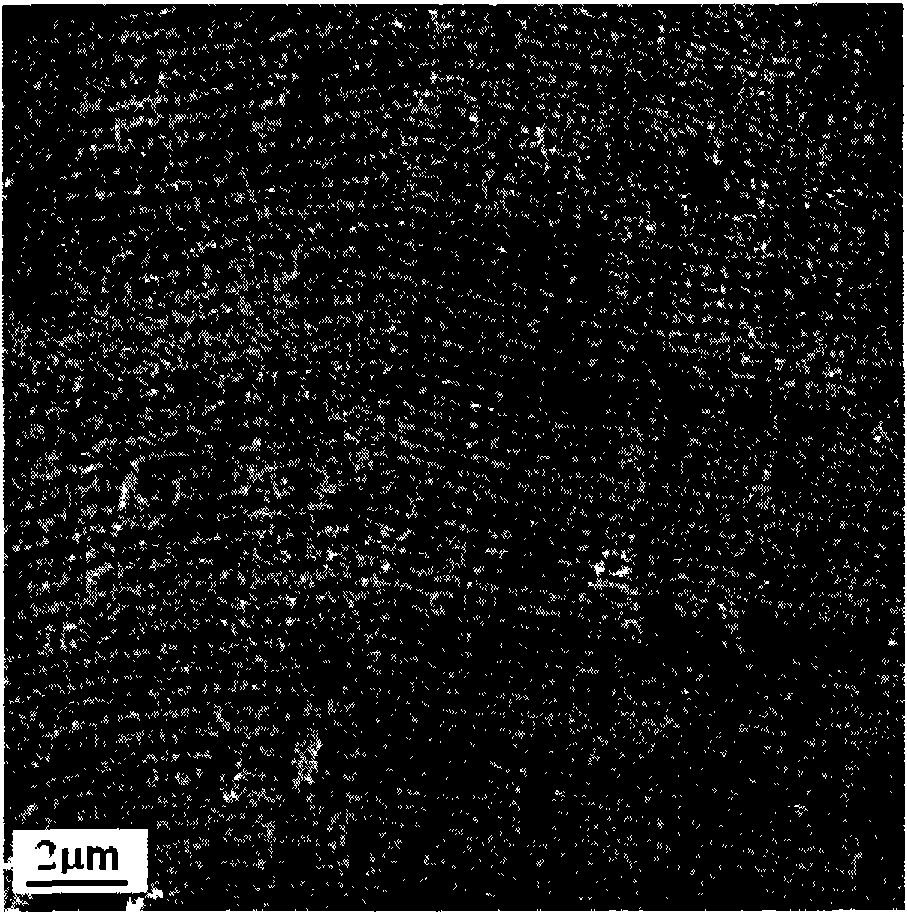

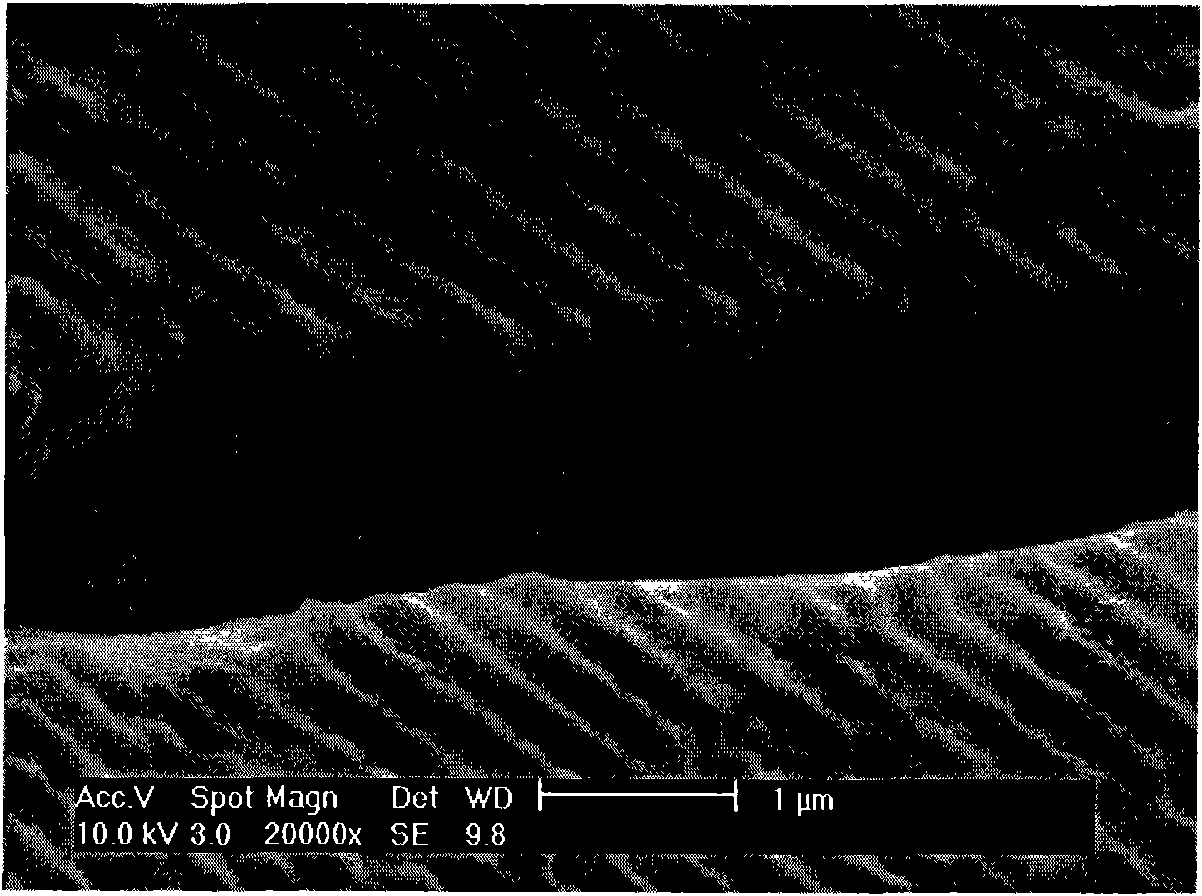

Image

Examples

Embodiment 1

[0086] Methyl methacrylate: 2-hydroxyethyl acrylate: vinyl acetate: methylvinyldimethoxysilane was mixed in a ratio of 30:20:20:30, and a monodisperse water-based polymer emulsion was prepared by emulsion polymerization.

Embodiment 2

[0088] Butyl acrylate: methacrylic acid: styrene: methacrylamide was mixed in a ratio of 60: 10: 20: 10, and a monodisperse water-based polymer emulsion was prepared by a dispersion polymerization method, and water-based nano-titanium dioxide particles with a particle size of 4 nm were added. Stirring at 100 rpm for 60 minutes to prepare nanocomposite emulsion, the dosage of nano titanium dioxide particles is 10wt%.

Embodiment 3

[0090] Mix methylstyrene: perfluoropropyl vinyl ether and butyl acrylate in a ratio of 50:30:20, prepare a monodisperse water-based polymer emulsion by emulsion polymerization, add water-based nano barium titanate particles with a particle size of 50nm, Stirring at 500 rpm for 60 minutes to prepare a nano-composite emulsion, the amount of nano-barium titanate particles is 1 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com