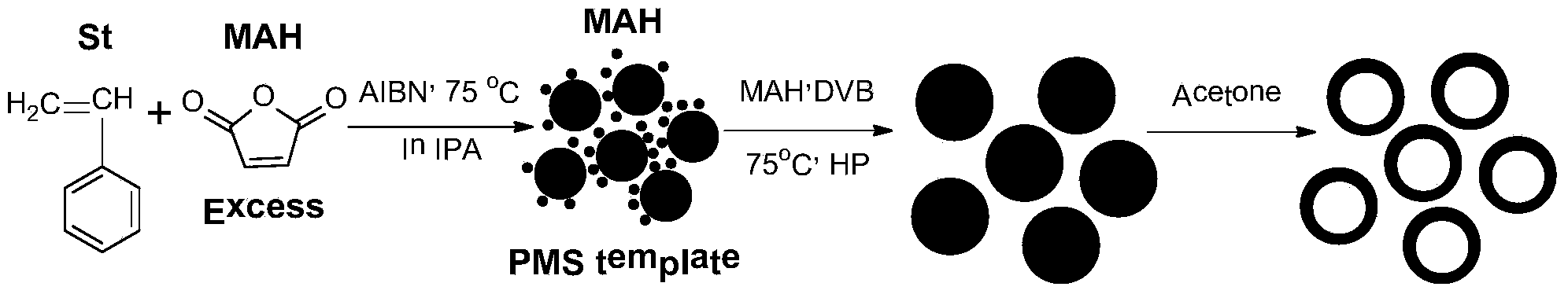

Preparation method of functional hollow polymer microspheres

A polymer and functional technology, applied in the field of hollow polymer microspheres and its preparation, can solve problems such as complex preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Example 1 (see Table 1 for specific monomer ratios, solvents, and initiator formulations)

[0076] Add 2.15g of monomer vinyl acetate, 4.90g of maleic anhydride, and 0.070g of AIBN initiator into the reaction flask, add 25mL of butyl acetate to dissolve, stir, mix well, and pass nitrogen gas for 30 minutes to remove dissolved oxygen. After that, the reaction system gradually The temperature was raised to the reaction temperature of 75°C, and the condenser condensed and refluxed. After reacting to the set time, stop heating, and obtain monodisperse PMV copolymer microsphere 1# after cooling. For styrene, 1.30g of monomer styrene, 2.45g of maleic anhydride, and 0.040g of AIBN initiator were added to the reaction flask, and 25mL of isoamyl acetate was added to dissolve and stir, and after mixing evenly, pass nitrogen for 30 minutes to remove dissolved oxygen. Afterwards, the temperature of the reaction system was gradually raised to the reaction temperature of 75° C., and...

Embodiment 2

[0083] Cool the suspension dispersion system of monodisperse PMV microsphere 1# to 30°C, start stirring to disperse PMV polymer microspheres evenly in the system, add 12.5mL n-heptane, MAH 2.45g and DVB 2.3g under stirring condition Add 0.025g of BPO initiator to the above-mentioned PMV dispersion liquid, dissolve and disperse evenly, and add 0.025g of BPO initiator to the above-mentioned reaction system. The temperature of the reaction system is gradually raised to 85°C, and the polymerization is kept at a constant temperature for 3 hours to obtain PMV particles as the core and DVB-MAH as For the core-shell polymer particles of the cross-linked shell layer, add 50 mL of solvent acetone to the dispersion system of the above-mentioned core-shell polymer particles, stir for 30 minutes, centrifuge, and dry to obtain the DVB-MAH hollow polymer microspheres of the present invention. The core-shell ratio of the hollow polymer microsphere is 1:1 (specifically refers to the mass ratio ...

Embodiment 3

[0085] Cool the suspension dispersion system of monodisperse PMV microspheres 2# to 30°C, start stirring to disperse the PMV polymer microspheres evenly in the system, and mix 12.5mL of n-hexane and 0.675mL of 1,4-butadiene under stirring conditions. g is added to the PMV dispersion liquid, after the dispersion is uniform, 0.0150 g of AIBN initiator is added to the above reaction system, the temperature of the reaction system is gradually raised to 75 ° C, and the polymerization is kept at a constant temperature for 3 hours to obtain PMV particles as the nucleus, butadiene- Maleic anhydride is the core-shell polymer particle of the cross-linked shell layer, and the monomer conversion rate is above 99%; 50 mL of solvent acetone is added to the dispersion system of the above-mentioned core-shell polymer particle, stirred for 30 minutes, centrifuged, and dried to obtain The butadiene-maleic anhydride hollow polymer microsphere of the present invention has a core-shell ratio of 1:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com