Three-dimensional ordered macroporous alumina and preparation method thereof

A macroporous alumina, three-dimensional ordered technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of low adhesion, collapse of macroporous structure, low mechanical strength, etc., to improve adhesion and good hydrophilicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

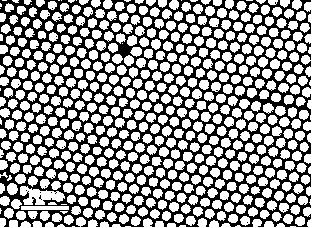

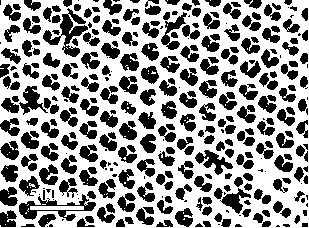

Image

Examples

Embodiment 1

[0029] Synthesis of Monodisperse Polymer Microspheres. Take 135 mL of twice distilled water and add it to a three-neck flask, then place the flask in a water bath and heat it to 75°C. Add 0.1348 g NaHCO 3 , start the stirrer, and start feeding N at the same time 2 , stabilized for 10 minutes to make NaHCO 3 Fully dissolve. Then add 0.0666 g of emulsifier and stabilize for 10 minutes, then add 30.7 mL of styrene (St) monomer and stabilize for 30 minutes. Finally, 0.1368 g of initiator potassium persulfate (KPS) was added. The reaction system was kept at a constant temperature of 75° C., and the stirrer rotated at 300 rpm. After 20 hours of reaction, the reaction was terminated, cooled naturally to room temperature, and the reaction mother liquor was left standing for future use. In this example, monodisperse polystyrene microspheres with a diameter of 240 nm were obtained. The specific test data are shown in Table 1.

[0030]

Embodiment 2~5

[0032] According to the method of Example 1, polystyrene emulsion microspheres with different particle sizes can be synthesized by changing the dosage of each reagent. The specific test data are shown in Table 1.

[0033]

[0034] Table 1 Polystyrene microspheres prepared by styrene emulsion polymerization

[0035] St / mL Emulsifier / mL NaHCO 3 / g KPS / g h 2 O / mL Reaction temperature / ℃ Particle size / nm Example 1 30.7 0.0666* 0.1348 0.1368 230 75 240 Example 2 28.6 0.2345 # 0.1385 0.1323 230 80 65 Example 3 29.4 0.0496* 0.1011 0.1293 230 80 330 Example 4 32.7 0.0278* 0.1334 0.1378 230 75 430 Example 5 35.4 0.0325* 0.1395 0.1386 230 75 780

[0036] # The emulsifier used is sodium lauryl sulfate;

[0037]*The emulsifier used was sodium p-styrenesulfonate.

[0038]

Embodiment 6

[0040] Measure 100 mL of the polystyrene microsphere emulsion obtained in Example 1, add sucrose and concentrated sulfuric acid to the emulsion, and the amount of the two accounts for 5.0wt% and 1.5wt% of the polystyrene microsphere emulsion respectively. After the emulsion was centrifugally settled, the liquid phase was removed, and after drying at 60° C. for 48 hours, a modified polymer microsphere colloidal crystal template with a particle size of 5 mm was obtained, which was named T6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com