Small-particle-size carboxylic styrene-butadiene latex and its preparation method

A technology of carboxylated styrene-butadiene latex and small particle size, which can be used in coatings, paper coatings, textiles and papermaking, etc. It can solve the problems that the particle size of latex cannot be adjusted and affects the fluidity of latex, and achieves excellent mechanical stability and chemical stability. The effect of stability, good fluidity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

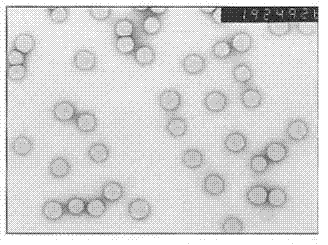

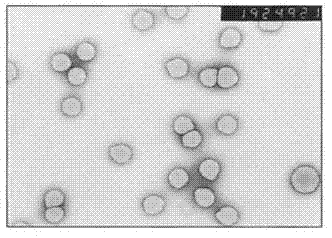

Image

Examples

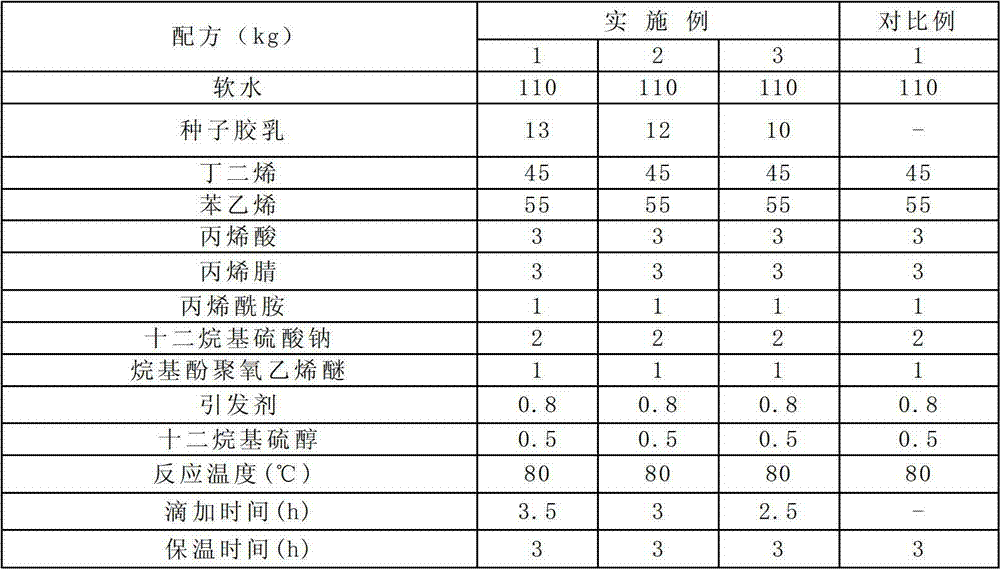

Embodiment 1

[0030] A, raw material components of seed latex and preparation method thereof:

[0031] 1. seed latex comprises the raw material component of following parts by weight:

[0032] Soft water: 250-350 parts, Butadiene: 10-30 parts, Styrene: 70-90 parts, Composite emulsifier: 10-15 parts, Initiator: 0.2-1.2 parts, Molecular weight regulator: 0.1-0.6 parts, As well as electrolytes, chelating agents and pH buffers required for emulsion polymerization;

[0033] ②The preparation method of seed latex:

[0034] After evacuating the polymerization tank, put in the above soft water, compound emulsifier, molecular weight regulator, pH buffer, butadiene, styrene, and electrolyte and chelating agent required for emulsion polymerization. After heating up to 40-60°C, add initiator agent, react for 10-15 hours, react until the conversion rate reaches more than 98%, and then cool down to below 30°C to synthesize seed latex;

[0035] B, raw material components of carboxylated styrene-butadien...

Embodiment 2

[0044] The raw material components of the seed latex and the carboxylated styrene-butadiene latex and the preparation method thereof are similar to the above-mentioned embodiment 1, and are not repeated herein.

[0045]In the above-mentioned Example 2, the molecular weight regulator, compound emulsifier, unsaturated carboxylic acid, and functional monomers are all similar to those in Example 1, and will not be repeated here.

[0046] The small-diameter carboxylated styrene-butadiene latex prepared by the above-mentioned preparation method has a particle diameter of 80-100nm.

[0047] As one of the most optimized technical solutions, in the present embodiment 2, soft water is 310kg in the preparation of seed latex, and composite emulsifier is 11kg, and butadiene is 15kg, and styrene is 85kg, and initiator is 0.4kg, and reaction temperature The temperature is 48°C, and the reaction time is 14 hours; the preparation of carboxylated styrene-butadiene latex is 12kg of seed latex, a...

Embodiment 3

[0049] The raw material components of the seed latex and the carboxylated styrene-butadiene latex and the preparation method thereof are similar to those of the above-mentioned embodiment 1 or 2, and are not repeated herein.

[0050] In the above-mentioned embodiment 3, the molecular weight regulator, complex emulsifier, unsaturated carboxylic acid, and functional monomers are all similar to those in embodiment 1 or 2, and will not be repeated here.

[0051] The small-diameter carboxylated styrene-butadiene latex prepared by the above-mentioned preparation method has a particle diameter of 80-100nm.

[0052] As one of the most optimized technical solutions, in the present embodiment 3, soft water is 330kg in the preparation of seed latex, and composite emulsifier is 13kg, and butadiene is 22kg, and styrene is 78kg, and initiator is 0.7kg, and reaction temperature It was 55 DEG C, and the reaction time was 11 hours; the seed latex in the preparation of carboxylated styrene-buta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com