A preparation method of an amphiphilic surfactant and a controllable preparation method of zwitterionic nano hollow capsules

A technology of surfactant and zwitterion, which is applied in the field of preparation of functional polymer materials by active controllable radical polymerization, can solve the problems of cumbersome preparation process, unsuitability for nano-polymer capsules, low hollow rate, etc., and achieve optimal shell The effect of layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

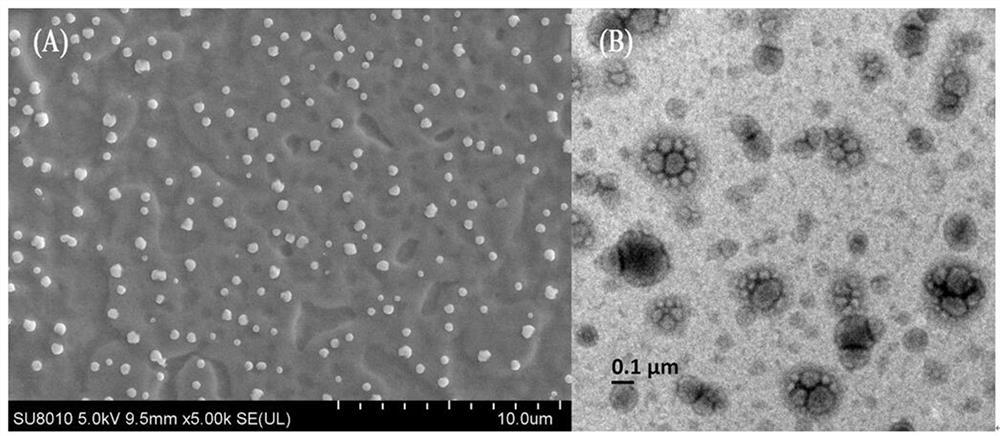

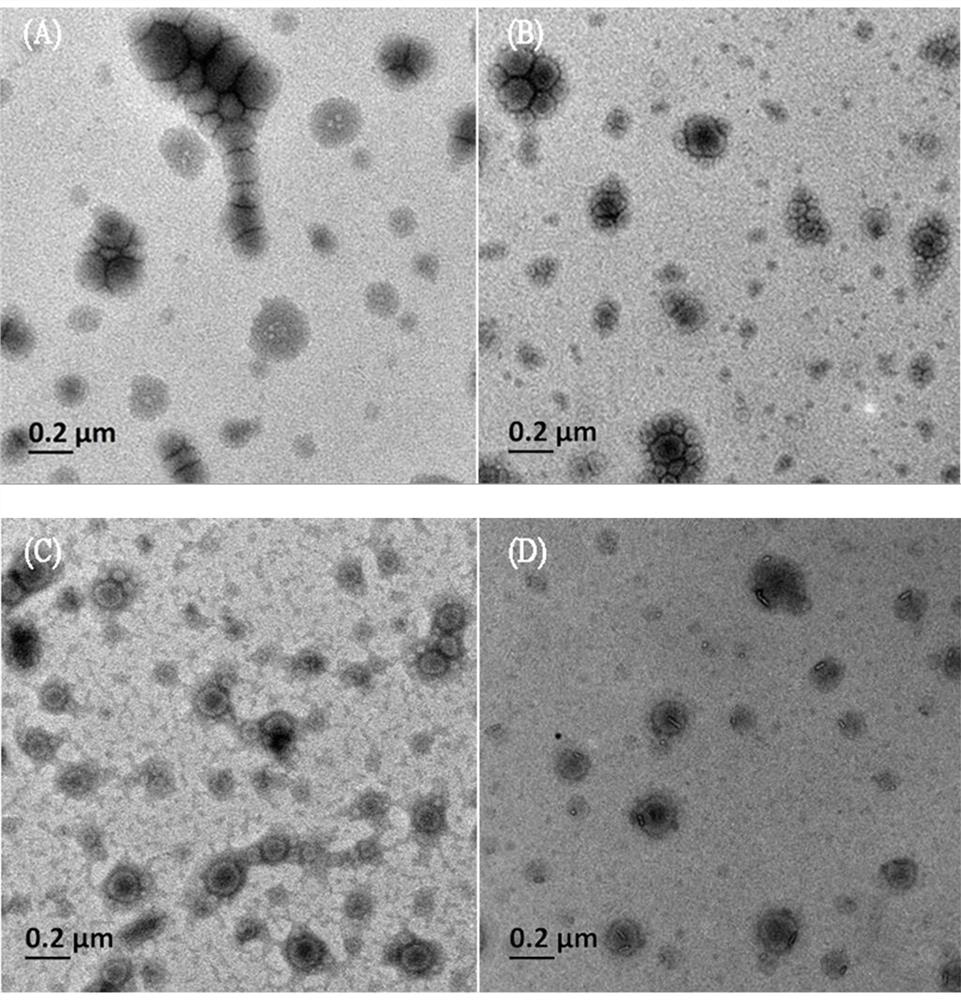

Image

Examples

Embodiment 1

[0034] Prepare a RAFT reagent with acrylic acid at the hydrophilic end and methyl acrylate at the lipophilic end, named R 0 ,Specific steps are as follows:

[0035] 0.1g 2-(dodecyltrithiocarbonate group)-2-methylpropionic acid, 0.3956g acrylic acid, 13.4670g methyl acrylate and 0.0135g azobisisobutyronitrile were dissolved in 20g dioxane In the solvent, magnetic stirring is used to form a homogeneous solution, and the polymerization reaction is carried out at 80° C. for 8 hours, and the amphiphilic RAFT reagent is obtained by ice methanol precipitation and vacuum drying to remove the solvent.

Embodiment 2

[0037] Prepare the RAFT reagent whose hydrophilic end is SBAA and the lipophilic end is styrene, named R 1 ,Specific steps are as follows:

[0038] 0.1 g of 2-(dodecyltrithiocarbonate)-2-methylpropionic acid was dissolved in 0.4 g of dioxane solvent, 0.7637 g of SBAA, 5.7143 g of styrene and 0.0135 g of azobis Isobutyronitrile is dissolved in benzyl alcohol, the above two solutions are mixed evenly, polymerized at 80°C for 8 hours, and the amphiphilic RAFT control agent is obtained by ice methanol precipitation and vacuum drying to remove solvent.

Embodiment 3

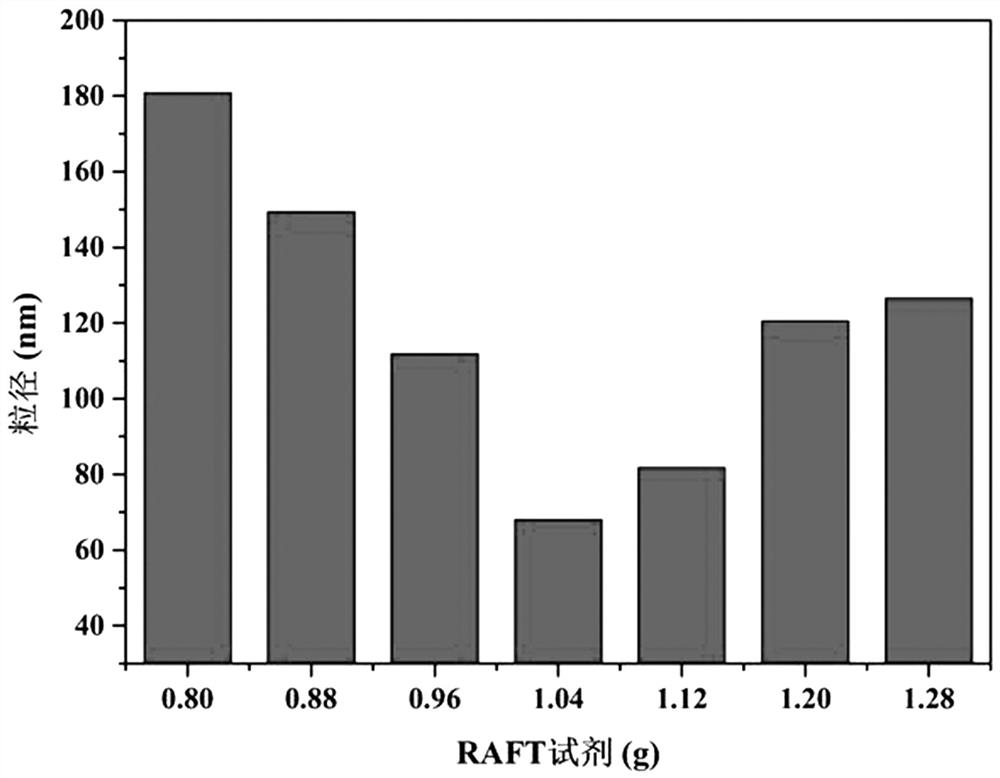

[0040] The method of embodiment 3-6 is identical with embodiment 1, difference is that SBAA consumption is successively 0.9929g (embodiment 3), 1.2220g (embodiment 4), 1.4511g (embodiment 5), 1.5275g (embodiment 6), styrene consumption is successively 8.5714g (embodiment 3), 11.42857g (embodiment 4), 14.2857g (embodiment 5), 16.2857g (embodiment 6), named after R 2 , R 3 , R 4 , regulate the chain length of RAFT reagents, and seek the structure of RAFT reagents with higher surface activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com