Preparation method of ferroferric oxide nanoparticles

A technology of ferroferric oxide and nanoparticles, which is applied in the direction of iron oxide/iron hydroxide, nanotechnology, ferrous oxide, etc., and can solve the problem of wide particle size distribution range and fine particle size of nanometer ferric oxide particles. It is difficult to meet the requirements of nanoscale and uneven particle size distribution, and achieve the effect of low price, convenient large-scale production, and easy control of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

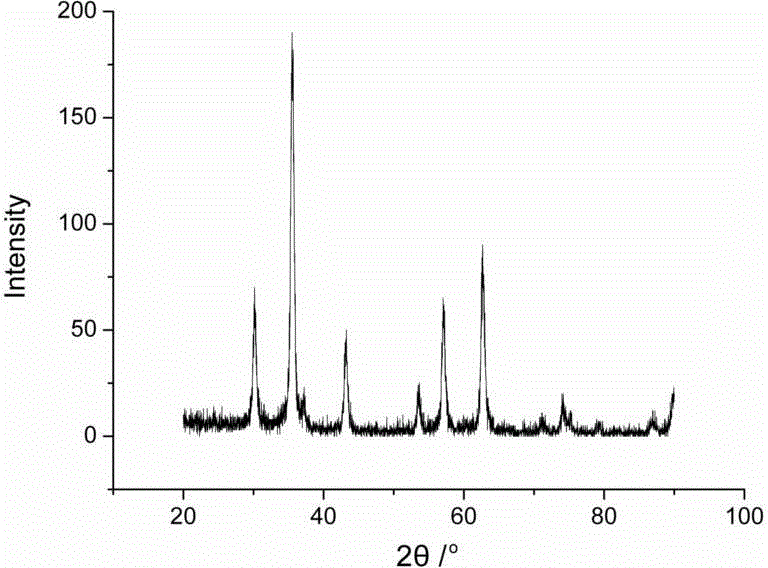

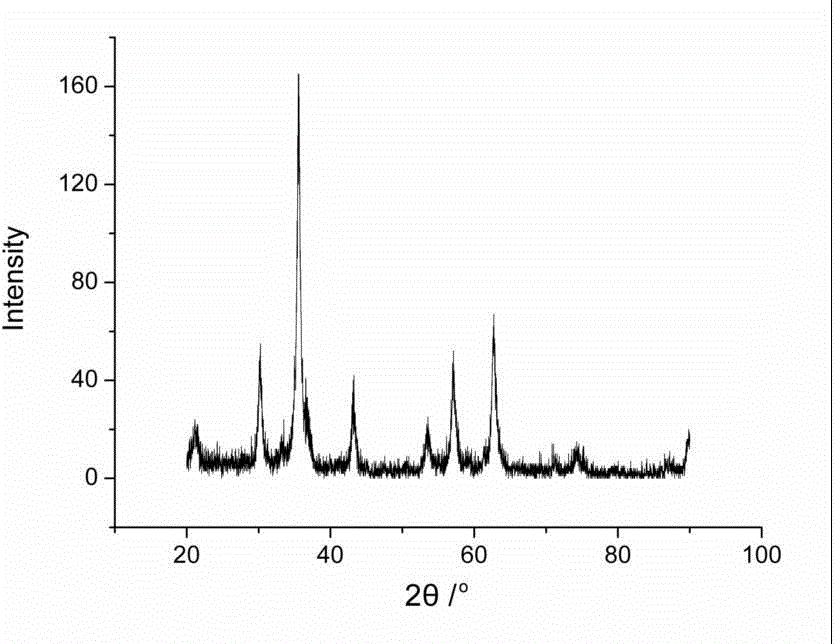

Image

Examples

preparation example Construction

[0024] A preparation method of iron ferric oxide nanoparticles, the particle size of iron ferric oxide nanoparticles is 14.0-19.0 nm, the steps of the preparation method are:

[0025] Step 1. Take 0.01 mol-0.03 mol ferric ammonium sulfate and ferrous ammonium sulfate respectively according to the molar ratio, and add ferric ammonium sulfate and ferrous ammonium sulfate to 40-120 ml with a molar concentration of 0.1-1.5 mol L -1 in the sodium sulfate solution, put it into a mixer, and stir for 10-20 minutes at a speed of 200-300 rpm to obtain a dispersion mixture of iron source and ferrous source, and set aside;

[0026] Step 2: Take 0.02-0.03 mol of sodium hydroxide in molar ratio, and add sodium hydroxide to 30-45 ml with a molar concentration of 0.1-1.5 mol L -1 In the sodium sulfate solution, put it in the mixer, stir for 10-20 minutes with the rotating speed of 200-300 rev / min, make the alkali source dispersion solution, set aside;

[0027] Step 3: Heat the alkali source ...

Embodiment 1

[0035]A preparation method of iron ferric oxide nanoparticles, comprising the steps of:

[0036] Step 1. Take 0.01 mol ferric ammonium sulfate and 0.01 mol ferrous ammonium sulfate in molar ratio, and add ferric ammonium sulfate and ferrous ammonium sulfate to 40 ml with a molar concentration of 0.1 mol L -1 in the sodium sulfate solution, put it into a mixer, and stir it for 10 minutes at a speed of 200 rpm to obtain a dispersed mixed solution of iron source and ferrous source, and set aside;

[0037] Step 2: Take 0.02 mol of sodium hydroxide in molar ratio, and add sodium hydroxide to 30 ml with a molar concentration of 0.1 mol L -1 in the sodium sulfate solution, put it into the mixer, and stir for 10 minutes with the rotating speed of 200 rev / min to prepare the alkali source dispersion solution, and set aside;

[0038] Step 3: Heat the alkali source dispersion solution to 80°C, add the iron source and ferrous source dispersion mixed solution while stirring, stir until bla...

Embodiment 2

[0044] A preparation method of iron ferric oxide nanoparticles, comprising the steps of:

[0045] Step 1. Take 0.01 mol ferric ammonium sulfate and 0.02 mol ferrous ammonium sulfate in molar ratio, and add ferric ammonium sulfate and ferrous ammonium sulfate to 80 ml with a molar concentration of 0.5 mol L -1 In the sodium sulfate solution, put in the mixer, stir with the rotating speed of 200 revs / min for 13 minutes, obtain the dispersion mixed solution of iron source and ferrous source, for subsequent use;

[0046] Step 2: Take 0.02 mol of sodium hydroxide in molar ratio, and add sodium hydroxide to 30 ml with a molar concentration of 0.5 mol L -1 In the sodium sulfate solution, put into the mixer, stir for 13 minutes with the rotating speed of 200 revs / min, make alkali source dispersion solution, for subsequent use;

[0047] Step 3. Heat the alkali source dispersion solution to 83°C, add the iron source and ferrous source dispersion mixed solution while stirring, stir unti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com