Method for preparing dual-structure flocky ZnO-base transparent conductive thin film

A technology of transparent conductive film and double structure, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of adding process steps to anti-reflective films, achieve low manufacturing costs, avoid excessively high etching rates, and avoid poor controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

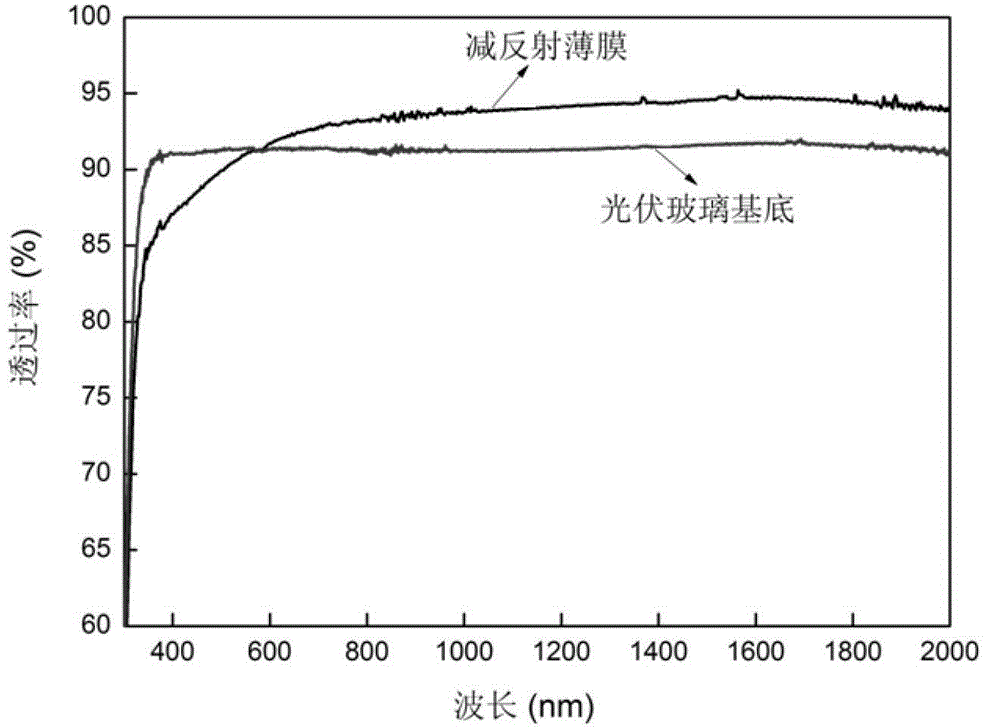

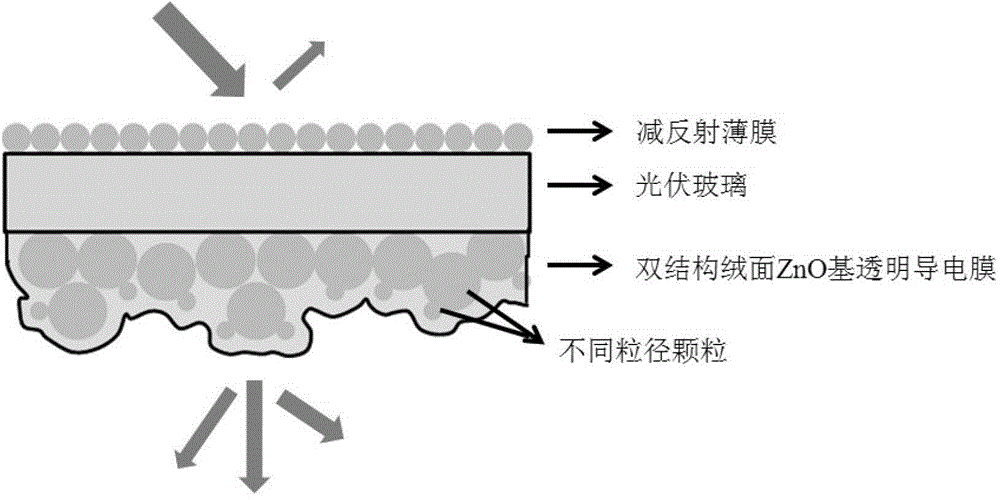

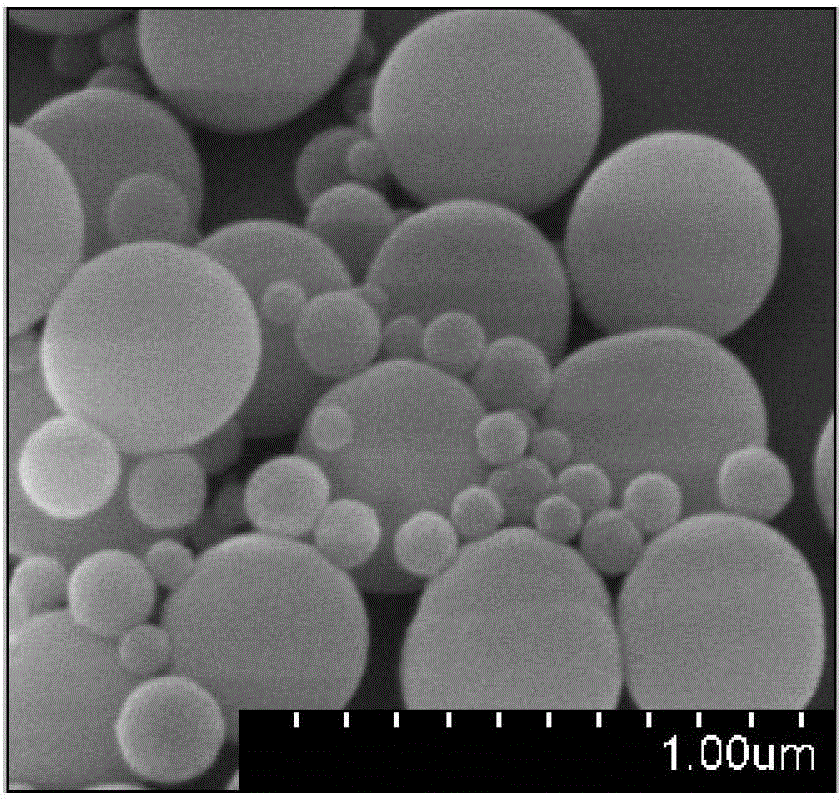

[0036] Example 1: Mix 12 mL of tetraethyl orthosilicate, 40 mL of ammonia, 28 mL of deionized water and 125 mL of ethylene glycol, and stir at room temperature with a magnetic stirrer for 8 hours; then add 12 mL of tetraethyl orthosilicate and 2mL of deionized water, continue to stir for 8 hours to obtain solution A containing large particles; mix 8mL of tetraethylorthosilicate, 14mL of ammonia, 20mL of deionized water and 150mL of ethanol, and stir for 8 hours at room temperature with a magnetic stirrer , Obtain solution B containing small particles; the difference in particle size between large particles and small particles is 250-350nm; mix solution A and solution B at a volume ratio of 1:1 for 3 hours to obtain mixed solution C; With a pulling speed of 1000 μm / s, the mixed solution C was coated on one side of the photovoltaic glass substrate, and then the solution B was coated on the other side of the photovoltaic glass substrate, and then dried at 200°C for 30 minutes; usin...

Embodiment 2

[0037] Example 2: Mix 8 mL of methyl orthosilicate, 14 mL of ammonia, 20 mL of deionized water and 150 mL of isopropanol, and stir at room temperature with a magnetic stirrer for 9 hours; then add 8 mL of methyl orthosilicate and 2 mL to Ionized water, continue to stir for 8 hours to obtain solution A containing large particles; mix 8mL of tetraethyl orthosilicate, 5mL of ammonia, 12mL of deionized water and 150mL of isopropanol, and stir for 6 hours at room temperature with a magnetic stirrer , The solution B containing small particles is obtained; the size difference between the large particles and the small particles is 250~350nm; the solution A and solution B are mixed and stirred at a volume ratio of 2:1 for 3 hours to obtain a mixed solution C; The mixed solution C was coated on one side of the photovoltaic glass substrate at a speed of 3000r / s, and then the solution B was coated on the other side of the photovoltaic glass substrate, and then dried at 150°C for 40 minutes;...

Embodiment 3

[0038] Example 3: Mix 8 mL n-butyl titanate, 12 mL ammonia, 16 mL deionized water and 150 mL ethanol, and stir at room temperature for 8 hours with a magnetic stirrer; then add 8 mL n-butyl titanate and 1 mL deionized water Water, continue to stir for 8 hours to obtain solution A containing large particles; take 4mL of n-butyl titanate, 6mL of ammonia, 10mL of deionized water and 150mL of ethanol and mix, stir at room temperature with a magnetic stirrer for 5 hours to obtain a solution containing small Solution B of particles; The difference in particle size between large particles and small particles is 250~350nm; Mix solution A and solution B in a volume ratio of 1:2 for 4 hours to obtain mixed solution C; spray mixed solution C to coat On one side of the photovoltaic glass substrate, solution B was then coated on the other side of the photovoltaic glass substrate, and then dried at 250°C for 25 minutes; the photovoltaic glass substrate was coated with mixed solution C and dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com